اطلب اقتباس

cil tank bottom wet ball mill

Comprehensive Guide to CIL Process - JXSC Machine

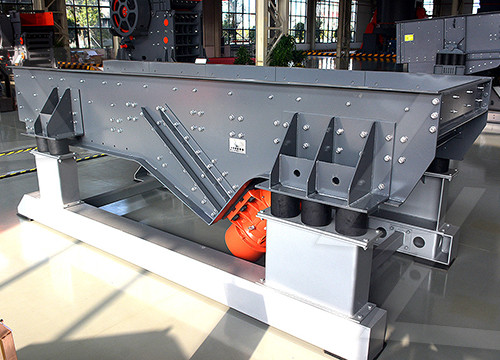

2023/10/16 Ball Mills; Batch Small Ball Mill; Raymond Grinding Mill; Wet Pan Mill; Feeding Machine. Vibratory Feeder; Electromagnetic Vibrating Feeder; Plunger Ore

获取价格

Gold CIL Processing Plant - JXSC Machinery

How To Choose Ball mill Or Wet Pan Mill In Grinding Gold

2024/8/14 Wet disc mills generally have simpler mechanical structures and fewer moving parts than traditional ball mills, which can mean lower downtime and operating

获取价格

CIP/CIL Modelling - AusIMM

The SGS carbon-in-pulp (CIP) / carbon-in-leach (CIL) modelling packaged is used to: Estimate the performance of a full-scale CIP and CIL plant. Derive the optimum design

获取价格

Gold Leaching Carbon in Leach - JXSC Machine

The gold leaching( carbon in leach) process has been widely used in newly built gold leaching plants in recent years, and many plants are changing into CIL as well.The gold-leaching CIL process is suitable for treating

获取价格

Insights From Simulation of a CIL/CIP Circuit - 911 Metallurgist

The leaching profiles generated by these parameters are illustrated in Figure 1. The profiles are for an ore feed rate of 209 t/h at 38 per cent solids to a series of tanks of 840 m3

获取价格

CIL System - Prominer

Prominer can provide the complete solution for CIL (carbon in leaching) system, which is a simultaneous leach and absorption process separate from CIP (Carbon in pulp), include

获取价格

Modern Wet Milling and Material Processing 2012-11

2012/11/1 Traditional Wet Milling. The coatings industry is no different from others in its search for modern manufacturing techniques. The traditional high-speed dissolver, ball mill, vertical mill and standard

获取价格

Gold CIP CIL Plant _The Nile Co., Ltd.

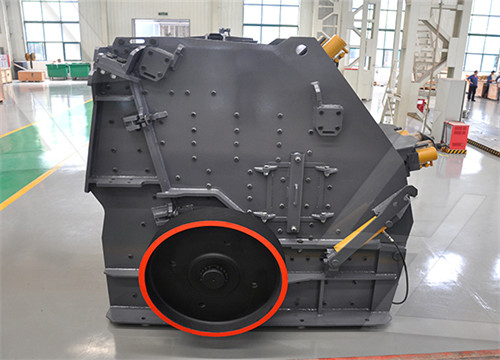

CIL is cyanide gold extraction process. Firstly, raw material is crushed into less than 10mm by different types of crushers; secondly, crushed material will be ground and classified into 90% of 200mesh, then fine powder will

获取价格

Ball Mill VS Rod Mill: Difference Selection - JXSC Machine

2024/1/10 Ore discharge method. Ball mills can be divided into overflow-type and grid-type, while rod mills are classified into overflow-type and open-type rod mills.. Among ball mills, the commonly used ones are grid-type ball mills and overflow-type ball mills (named from different structures of the ore discharge parts), while rod mills do not use

获取价格

The Difference Between CIP and CIL Beneficiation Processes in

2024/2/10 2. CIL process: The equipment of CIL process mainly includes crusher, ball mill, stirring tank, activated carbon adsorption column and filter. The crushing and grinding stages are usually carried ...

获取价格

Research on Treatment of Oily Sludge from the Tank Bottom by Ball

2020/5/20 Difficult separation of oil-solid phase and high fine content of the recovered oil were two problems in the treatment of oily sludge from the tank bottom by the hot water-based extraction process. To solve the problems, one technology with "ball milling + ozone-catalyzed oxidation" as the core was s

获取价格

How Many Types of Ball Mill? - JXSC Machine

2019/12/26 2. Edge transmission ball mill: The motor drives the gear on the edge of the barrel through the reducer to drive the barrel. Ball mill grinding conditions. 1. Wet ball mill: Water is added at the same time as the material is fed, and the material is discharged into a certain concentration of slurry and discharged.

获取价格

Inventory Of Common Faults And Solutions Of Mining Ball Mill

2024/8/14 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency. One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency. Additionally, worn or damaged liners can hinder the grinding process by reducing the

获取价格

Energy Saving Ball Mill_The Nile Co., Ltd.

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between 0.074 mm and 0.4 mm in diameter.

获取价格

What’s the Difference Between SAG Mill and Ball Mill

2019/11/26 The ball mill adopts a discharge screen similar to the ball mill, and the function of blocking the internal medium of the overflow ball mill is accomplished inside the rotary part of the ball mill. The discharge screen is only responsible for forcing out a small amount of the medium that overflows into the discharge screen through the internal ...

获取价格

What is Wet Grinding Process Wet Ball Milling Method and

The Wet Milling Method: A Deep Dive. Wet milling, a core aspect of the wet grinding process, involves breaking down materials in a liquid medium. The wet ball milling process, a popular choice in many sectors, employs a ball mill to achieve a fine grind. This method is particularly effective for materials that are too hard for standard milling ...

获取价格

Gold Processing Plant Multotec

A semi-autogenous mill (SAG) or ball mill is then used to grind and crush the gold ore to a smaller particle size. After this milling, the stream is fed to a trommel screen and next, a cyclone circuit. Cyclones, which are set at the appropriate cut point, separate correctly sized particles from larger ore particles.

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Some of the media falls and impacts the ore particles at the bottom of the mill. The rest of the media cascades and, in the process, creates particle breakage by attrition. ... For wet ball mills, Bond expressed power draw as a function of the total mass of media:P↓M / M↓B – 15.6Φ↓V (1 – 0.937 J↓B) ...

获取价格

Ball Mill Parameter Selection Calculation - JXSC

2019/8/30 V — Effective volume of ball mill, m3; G2 — Material less than 0.074mm in product accounts for the percentage of total material, %; G1 — Material less than 0.074mm in ore feeding accounts for 0.074mm in the percentage of the total material, %; q’m — Unit productivity calculated according to the new generation grade (0.074mm),

获取价格

Wet Pan Mill - JXSC Machinery - Mineral Processing

Introduction: The wet pan mill is the full name of the wet pan grinding mill, gold pan mill, or wheel pan mill.According to the different applications, it is divided into the gold mill, amalgam mill, iron mill, and electric mill; According to the different structure, it is divided into single pan mill, double pan mill and three pan mill. The equipment is mainly

获取价格

Ball Mill - Prominer - Prominer (Shanghai) Mining Technology Co.,Ltd.

We can design and manufacture grate type ball mill for mineral primary grinding and overflow type ball mill for mineral secondary grinding. The grinding media balls may be made of cast iron, steel, or ceramic, Correspondingly, the inner surface of the cylindrical shell is lined with an abrasion-resistant material such as manganese steel or ceramic.

获取价格

Exploring Ball Mill Diagram: A Comprehensive Guide - JXSC

2024/4/28 Explore the anatomy of a ball mill with a detailed ball mill diagram. Learn more on our blog for valuable insights into this essential industrial equipment. ... At low speeds, the grinding media rolls along the bottom of the mill without being lifted up by the sides. This mode is characterized by low-impact forces and is ideal for light ...

获取价格

Ball Mill Parameter Selection Calculation - JXSC

2019/8/30 V — Effective volume of ball mill, m3; G2 — Material less than 0.074mm in product accounts for the percentage of total material, %; G1 — Material less than 0.074mm in ore feeding accounts for 0.074mm

获取价格

Wet Pan Mill - JXSC Machinery - Mineral Processing

Introduction: The wet pan mill is the full name of the wet pan grinding mill, gold pan mill, or wheel pan mill.According to the different applications, it is divided into the gold mill, amalgam mill, iron mill, and electric mill; According to the different structure, it is divided into single pan mill, double pan mill and three pan mill. The equipment is mainly

获取价格

Ball Mill - Prominer - Prominer (Shanghai) Mining Technology Co.,Ltd.

We can design and manufacture grate type ball mill for mineral primary grinding and overflow type ball mill for mineral secondary grinding. The grinding media balls may be made of cast iron, steel, or ceramic, Correspondingly, the inner surface of the cylindrical shell is lined with an abrasion-resistant material such as manganese steel or ceramic.

获取价格

Exploring Ball Mill Diagram: A Comprehensive Guide - JXSC

2024/4/28 Explore the anatomy of a ball mill with a detailed ball mill diagram. Learn more on our blog for valuable insights into this essential industrial equipment. ... At low speeds, the grinding media rolls along the bottom of the mill without being lifted up by the sides. This mode is characterized by low-impact forces and is ideal for light ...

获取价格

Ball Mills Industry Grinder for Mineral Processing - JXSC Machine

A ball mill, also known as a ball grinding machine, is a well-known ore grinding machine widely used in mining, construction, and aggregate applications.JXSC started the ball mill business in 1985, supplying global services including design, manufacturing, installation, and free operation training.

获取价格

Modern Wet Milling and Material Processing - PCI Magazine

2012/11/1 Traditional Wet Milling. The coatings industry is no different from others in its search for modern manufacturing techniques. The traditional high-speed dissolver, ball mill, vertical mill and standard horizontal mill have been the primary methods used to mill pigmented materials for more than 50 years, and are still considered to be the industry

获取价格

Planetary Ball Mills 101 - Union Process

Like other ball mills, planetary ball mills provide a slight advantage in metal-free grinding, because an operator only needs to line the tank and use ceramic media to achieve a metal-free environment (as opposed to internally agitated ball mills, which require the arms and shaft to be sheathed, which is easily done).

获取价格

Everything You Need to Know About Wet Media Milling, Step

Wet media milling is an indispensable process for micronization and nanonization. Here’s a step by step guide to a toll manufacturer’s wet grinding process ... cascading type ball and/or bead mills, and basket or batch mills. Unlike dry mechanical and jet milling processes, wet milling requires multiple, specific steps that can vary based ...

获取价格

Wet Continuous Production Mills - Union Process

How Continuous Attritors Work The continuous Attritor is a compact vertical design suitable for continuous production of large quantities of materials. Advantages of using a continuous Attritor include continuous large production, fastest grinding and processing, excellent temperature control, simple and safe operation, and low power consumption. To learn

获取价格

Can the Ball Mill Grind the Material to 325 Mesh? - JXSC Machine

2019/11/18 The ball mill plays an important role in the mineral beneficiation production line, divide into overflow ball mill and grate ball mill, capable to grind various materials. The output material particle size of the ball mill is 18-200 mesh, which can be adjusted by customers according to their own production needs.

获取价格

Siltation of Ore Particles in Leaching Tanks: Causative Factors and ...

2016/12/1 The Bond Ball Mill Work Indices of the blends tested were between 16.4 kWh/t and 9.6 kWh/t and a blend ratio of 85% fresh and 15% weathered was found to have a Bond Ball Work Index almost equal to ...

获取价格

Lime Ball Mill - JXSC Machine

2019/12/5 It is important that is a local large-scale ball mill direct sales company in Henan, so in terms of the price of limestone wet ball mills Although the price of Red Star Limestone Wet Ball Mill may not be very low, under the premise of the same quality, the price of Red Star Limestone Wet Ball Mill is relatively favorable, so users and ...

获取价格

Planetary Ball Mill - JXSC Machine

【Structure】 The planetary ball mill consists of four grinding jars, stainless steel pressure rods, visible windows, hatch covers, planetary discs, and control systems. Filled with loose grinding balls, two superimposed rotary movements move the grinding jar. 【Working Principle】 The planetary ball mill is equipped with 4 grinding balls on a turntable.

获取价格

CIP/CIL Modelling - AusIMM

SAG/ball mill (gravity gold recovery in ball mill circuit), cyanidation and CIL Ore throughput progressively increased by ~300% from plant design: 4.8Mtpa to 12.0 Mtpa over first 5 years; seven open pits – blend of soft and hard ores; saprolitic Single CIL circuit (design) split into 2 parallel circuits – each with 1 leach

获取价格- الأسفلت خلط خطة اندونيسيا

- طاحونة كروية سعة 20 طن في الساعة في مصر

- تأثير نقطة كسارة العرض

- استهلاك الديزل من مخروط محطم

- طحن مطحنة لتعدين الذهب آلة

- كسارة الحجر المورد في السودان

- جنوب افريقيا مصانع الطوب

- ماليزيا المطرقة مطحنة الصانع

- محطة كسارة في tavarekere شمال شرق

- منغوليا كسارة صغيرة خام للبيع

- كسر مصنع للاسمنت

- محطم العمود الرأسي مقابل شيف صيانة كسارة

- سلامة كسارات الكوارتز

- كسارة الحجر مجموعة كاملة والرمل صنع محجر الحجر

- حجر المطحنة قائمة الأسعار اندونيسيا

- الخرسانة للبيع المملكة العربية السعودية

- قائمة أسعار الكسارات في المملكة العربية السعودية

- الخبث مطحنة عمودية

- thermal power plant process flow diagram

- استئجار صخرة أو الطوب كسارة صغيرة

- تأثير محطم للبيع في إندونيسيا

- طحن تجويف الكسارة الدورانية

- الرسم التقني كسارة الفك

- كسارات الصلب dymethaberry آثار جانبية

- مبادئ التشغيل في الكسارات الدورانية

- خام الذهب تجهيز العنقاء،

اقرأ أكثر

اقرأ أكثر