اطلب اقتباس

beneficiation of iron ore sulphur

Current strategies and future challenges on exploration,

The presence of these elements along with sulphur adversely affects the quality of iron ores and has a great bearing on performance of blast furnaces. Reduction of the alumina content in iron ore by 1% improves blast furnace performance by 3%, reduces reduction

获取价格

Towards a Sustainable and Enhanced Iron Ore Recovery: Bio

2024/3/16 An overview of iron ore beneficiation techniques, including their limitations and environmental concerns, iron ore bio-beneficiation techniques, and future outlook

获取价格

Advancing Iron Ore Beneficiation: Exploring Cutting-Edge

May 1, 2024. In the dynamic landscape of mining and metallurgy, the iron ore beneficiation process stands as a cornerstone, pivotal in transforming raw ore into high-grade iron

获取价格

Various Types Of Iron Ore Beneficiation Processes

2024/8/14 iron ore contain high sulfur, phosphorus Beneficiation. The common processes used to remove sulfur from iron ore concentrates are flotation and roasting. At the same time, the latter is costly and

获取价格

A critical review on metallurgical recovery of iron from iron ore ...

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of

获取价格

Beneficiation of Iron Ores – IspatGuru

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore. More than 85% of the hematite ore reserves

获取价格

Beneficiation: Quality Starts with the Ore — Metals

2017/2/1 In general, iron ore beneficiation is done at the mining site. The concentrated iron ore is subsequently sintered or pelletized, depending on the grain size distribution, before it is charged to an ironmaking plant.

获取价格

Existing and New Processes for Beneficiation of Indian Iron ores

2020/2/8 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making.

获取价格

Iron ore beneficiation: an overview - ResearchGate

2023/1/1 There is a need for the upgradation of ore and removal of deleterious alumina, phosphorous, and sulfur through beneficiation [2][3][4] [5] to develop mineral

获取价格

Advancing Iron Ore Beneficiation: Exploring Cutting-Edge

2024/5/1 Microorganisms capable of oxidizing sulfide minerals or producing bioflocculants aid in the removal of impurities and the concentration of iron-rich phases, offering sustainable and eco-friendly ...

获取价格

Beneficiation of Iron Ores – IspatGuru

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by

获取价格

Towards a Sustainable and Enhanced Iron Ore Recovery: Bio-beneficiation

2024/3/16 An overview of iron ore beneficiation techniques, including their limitations and environmental concerns, iron ore bio-beneficiation techniques, and future outlook toward mining sustainability, is presented and discussed in this manuscript. ... Shang H, Wen JK, Wu B, Mo XL (2015) Study on bioleaching of sulfur in iron ore by mixed

获取价格

Iron ore - Wikipedia

Lower-grade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, ... The importance attached to low-sulfur iron is demonstrated by the consistently higher prices paid for the iron of Sweden, Russia, and Spain from the 16th to 18th centuries. ...

获取价格

The Beneficiation Techniques for 5 Types of Iron Ores in Vietnam

2022/3/25 Siderite iron ore processing flow chart. Beneficiation techniques of limonite Theoretically, being rich in crystal water, limonite has a low grade. The iron concentrates can hardly be reached up to 60% according to physical dressing. ... and when processing and smelting iron ore, sulfur and phosphorus are more difficult to remove.

获取价格

Some factors that affect beneficiation of sulphide nickel–copper ores

2007/6/1 It usually contains calcium and sulphur with its compounds that take part in the surface reactions. In this article some characteristics of the flotation of nickel ores are considered. 2. Processing aspects2.1. The effect of serpentine mineralsA geological and mineralogical survey is usually done before beneficiation of the ore.

获取价格

Beneficiation of Iron Ore

Beneficiation of Iron Ore. The purpose of beneficiation is to provide the following advantages: less amount of added elements in the ore; ... acidic ,therefore the silica will be reduced through beneficiation process to about 5-8 % .Harmful component in the ore such as P, As, Cr, Cu, V, alkali, sulphur and Ti. 0.5%must be removed.

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore. More than 85% of the hematite ore reserves are of medium- to high-grade (+62% Fe) and are directly used in blast furnace and in direct-reduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and

获取价格

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017/2/1 In general, iron ore beneficiation is done at the mining site. The concentrated iron ore is subsequently sintered or pelletized, depending on the grain size distribution, before it is charged to an ironmaking plant. ... For an Indian customer with access to an untypical magnetite ore with an exceptionally high sulfur content, a feasible

获取价格

Sulphur removal of iron ore tailings by flotation: Journal of ...

2017/3/23 Beneficiation of iron ore tailings is a significant issue in the world steel industries, from the point of view of both pollution control and secondary resources. This investigation addressed the processing of tailings with high sulphur content from an iron ore concentrator to produce pellet feed fines and to prevent acid mine drainage. This ...

获取价格

Mineral processing - Wikipedia

Since then, many different technologies have been invented to replace the Bessemer process such as the electric arc furnace, basic oxygen steelmaking, and direct reduced iron (DRI). [5] For sulfide ores, a different process is taken for beneficiation. The ore needs to have the sulfur removed before smelting can begin.

获取价格

Simultaneous extraction of manganese from low grade

2002/4/1 Semantic Scholar extracted view of "Simultaneous extraction of manganese from low grade manganese dioxide ore and beneficiation of sulphur slag" by K. Abou-El-Sherbini. Skip to search form Skip to main ... Low-grade manganese oxide ore is generally characterized by high iron content. In this work, sulfidation roasting of an iron-rich

获取价格

Everything You Need to Know About Iron Ore Beneficiation

2022/12/2 Iron ore beneficiation is the process of improving the quality of iron ore by removing impurities and increasing its iron content. It is necessary to reduce alumina and silica in the feed. The process improves the chemical, physical, and metallurgical characteristics of the ore to make it a more desirable feed for iron-making furnaces.

获取价格

Developments in the physiochemical separation of iron ore

2015/1/1 In addition to silica, other impurities such as aluminum, phosphorus, and sulfur are also found in iron ores. In some cases, these impurities can be removed by flotation—strategies for the key impurities are discussed. ... In China, iron ore beneficiation started with the direct flotation of iron oxides using anionic collectors.

获取价格

Mineral processing - Wikipedia

Since then, many different technologies have been invented to replace the Bessemer process such as the electric arc furnace, basic oxygen steelmaking, and direct reduced iron (DRI). [5] For sulfide ores, a different process is taken for beneficiation. The ore needs to have the sulfur removed before smelting can begin.

获取价格

Simultaneous extraction of manganese from low grade

2002/4/1 Semantic Scholar extracted view of "Simultaneous extraction of manganese from low grade manganese dioxide ore and beneficiation of sulphur slag" by K. Abou-El-Sherbini. Skip to search form Skip to main ... Low-grade manganese oxide ore is generally characterized by high iron content. In this work, sulfidation roasting of an iron-rich

获取价格

Everything You Need to Know About Iron Ore

2022/12/2 Iron ore beneficiation is the process of improving the quality of iron ore by removing impurities and increasing its iron content. It is necessary to reduce alumina and silica in the feed. The process

获取价格

Developments in the physiochemical separation of iron ore

2015/1/1 In addition to silica, other impurities such as aluminum, phosphorus, and sulfur are also found in iron ores. In some cases, these impurities can be removed by flotation—strategies for the key impurities are discussed. ... In China, iron ore beneficiation started with the direct flotation of iron oxides using anionic collectors.

获取价格

Sustainable Use of Copper Resources: Beneficiation of Low-Grade

2022/4/27 The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, power transmission lines, alloying, anticorrosive coating, heat exchangers, refrigeration tubing, etc. Copper ore is primarily beneficiated from sulphide mineral deposits. Due to high-grade

获取价格

Mineral and Technological Features of Magnetite ... - ACS

2021/3/24 Impurities in the ore are represented by phosphorus and sulfur. For the studied ore, the presence of phosphorus can be noted. The content of phosphorus pentoxide was 0.14%. The sulfur content is in the range of 0.02–0.04%. ... Iron ore beneficiation technologies in Russia and ways to improve their efficiency. Journal of

获取价格

Environmental impact of mining and beneficiation of copper

2022/7/11 The mining and beneficiation process of one tonne copper sulfide ore is listed as a basic functional unit. 0.03 tonnes copper concentrate, 0.14 tonnes high-sulfur concentrate, and 0.02 tonnes low-sulfur concentrate obtained from one tonne raw ore were performed based on the economic allocation principle.

获取价格

Iron Ore Distribution across the World - PMF IAS

2016/1/24 Smelting, Beneficiation. Iron Ore Distribution Across the World. Factors that influence the location of Iron and Steel industry. Raw materials – iron ore, coal, limestone, etc. Transportation and other infrastructure – road, rail, ports etc. ... [Oxides decrease the strength of Iron] Sulphur. A VERY harmful element. Forms Iron Sulphide ...

获取价格

Application of biotechnology in iron ore beneficiation

2015/1/1 Shen et al. (2012) also found that acidophilic bioleaching microorganisms effectively bioleach phosphorus from iron ore when they added high-phosphorus iron ore and elemental sulfur to municipal wastewater to make an iron ore slurry. Apatite was the main phosphorus mineral in the iron ore and the wastewater contained native sulfur

获取价格

Iron Ore Beneficiation Plant - JXSC Machinery - Mineral Processing

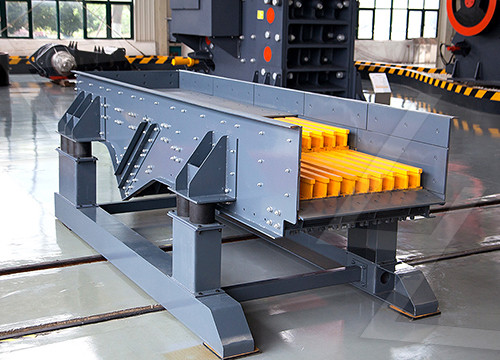

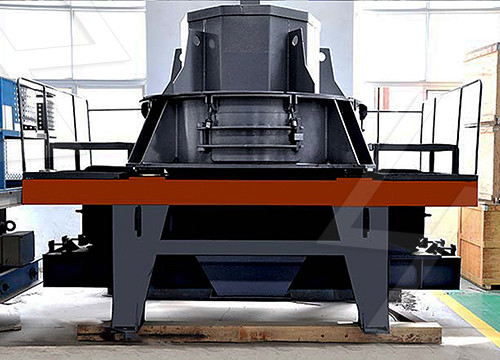

1. The dump truck feeds the raw ore into the hopper and the vibrating feeder. The vibrating feeder feeds evenly to the jaw crusher, which crushes large rocks to less than 200mm.. 2. The jaw crusher output is sent to the transfer bin through the belt conveyor, and an electromagnetic vibrating feeder is installed below it. Convey the material less than

获取价格

(PDF) Flotation of Iron Ores: A Review - ResearchGate

2019/11/19 Overview of the beneficiation process used by the Yuanjiacun iron ore concentrator, utilizing anionic reverse flotation (based on Chen, Ge and Yu 2005; Mao, Huang and Zhao 2005). Figures ...

获取价格

Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

impurities such as sulphur, phosphorous, arsenic, zinc, lead and other metals are to be also considered. The Al 2 O 3 / SiO 2 ratio should be less than one for blast furnace feed. The ... Low Grade Iron Ore Beneficiation In the past 50 years, due to high demand and intensive mining operations, the high grade

获取价格

Characterization of Sulfidation Roasting of an Iron-Rich

Low-grade manganese oxide ore is generally characterized by high iron content. In this work, sulfidation roasting of an iron-rich manganese oxide ore with elemental sulfur was characterized. The experimental results indicated that manganese dioxide can

获取价格

Iron Ore Geoscience Australia

2023/12/19 The latter property aids in the beneficiation of magnetite ores. Magnetite contains 72.4% Fe by molecular weight, which is higher than hematite, but magnetite ores having lower ore grade (generally 20-30% Fe) owing to the presence of impurities. ... sulphur and aluminium. Thus, magnetite pellets are a premium product and attract

获取价格- عال مكاين ثقيلة

- كسارة تصادم الفحم في إندونيسيا

- بطانات مطحنة الكرة الصلب الصب في الهند

- مصانع الخامات

- معامل تصنيع حبيبات المطاط سوريه الصنع

- اسماء اذوات البناء

- سعر كسارة الحجر الجيري سعر كسارة الخرسانة

- مطاحن أتريتوز حبة

- كسارات بنغالور كارناتاكا

- موردو معدات غسيل الرمال دبي

- ماكينات حفر معدات مناجم

- عملية تدفق كسارة الفك

- الشركة المصنعة لآلة رمل الحجر

- آلة طحن كرات الصلب

- شركات تعدين الذهب الصغيرة في الجزائر

- خطة تخطيط معدات المحاجر

- خط إنتاج الوحدة النمطية

- mobile crusher for peat 2cmoss

- كرارة خام الحديد الطواحين

- مصانع كسارة الصخور

- تعدين الفحم الخريطة

- محطة غسيل ياردة في الساعة

- محطم رمح التوأم للبيع

- تستخدم كسارة svedala الفك في السويد الألغام كسارة للبيع

- ناعورة مغسلة رمل مستعملة

- السلطة الكسارات شركتنا للبيع في هرقل

اقرأ أكثر

اقرأ أكثر