اطلب اقتباس

iron smelter slag chrusing methods

Extraction and separation of copper and iron from copper

2022/9/25 After cooling by the slag conveyor, the copper concentrate containing 29.44% copper and 30.39% iron and the iron concentrate containing 46.93% iron and

获取价格

(PDF) Metallurgical Processing Strategies for Metals Recovery from ...

2019/6/18 These methods include crushing, ma g- ... and iron fr om copper smelter slag. The slag obtained was. ... ered 52–61% c opper from bottom ash of incineration

获取价格

Life cycle assessment of melting reduction treatment for iron and

2022/11/1 Blast furnace slag is the waste slag discharged from smelting pig iron in the blast furnace, belonging to the water-quenched slag. ... and compared them with the

获取价格

Crystallization Behavior of Copper Smelter Slag During ... - Springer

2015/5/19 Copper slag is composed of iron silicate obtained by smelting copper concentrate and silica flux. One of the most important criteria for the utilization of this

获取价格

Copper Slag as a Source of Iron: An Overview SpringerLink

Abstract. The production of Copper slag occurs during the smelting of Cu, and it contains various compounds, including oxides of Fe, Cu, Co, Al, Si, Ni, Cr, and Ca. A significantly

获取价格

Crystallization Behavior of Copper Smelter Slag During

recycling iron from copper slag, such as the multistage grinding-mineral process, smelting reduction, sulfation method, and many hydrometallurgical methods.[2] In the current

获取价格

Recycling of iron and steel slag for carbon reduction and low ...

1 INTRODUCTION. Blast furnace slag (BFS) and steel slag (SS), as industrial solid wastes produced in the process of steel-making, account for 80%–90% of the total smelting

获取价格

Recent Trends in the Technologies of the Direct

2023/4/5 These methods include the Blast furnace/Blast Oxygen Furnace [5, 6], Direct Reduction Method , Indirect Reduction Method [8, 9], and Reducer-Smelter Process [10, 11, 12]. Thus, it is, therefore crucial

获取价格

Efficient Recovery of Platinum Group Metals from Spent

Efficient Recovery of Platinum Group Metals from Spent Automotive Catalysts Using Iron Smelting Method by Optimizing Slag Composition at Low Temperature JOM ( IF 2.1)

获取价格

Ferrous metallurgy - Wikipedia

Bloomery smelting during the Middle Ages.. Ferrous metallurgy is the metallurgy of iron and its alloys.The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, [1] were made from

获取价格

By the hand of the smelter: tracing the impact of decision-making

2022/4/4 Slag analyses from archaeological iron smelting sites are common. Rigorous analyses of iron and slag from successful experimental smelting, however, are still rare. Furthermore, thorough analyses from a series of smelts, and of the slag produced in different phases of the smelt, are exceedingly rare. The present study investigates the

获取价格

The Recovery of Copper from Smelting Slag by Flotation Process

2017/2/8 Materials. The smelting slag used in this study was obtained from a copper plant in China. Mineralogical analysis, performed using scanning electron microscope (SEM) and energy dispersive X-ray spectroscope (EDS), polarizing microscope and X-ray diffraction (XRD), indicated that fayalite (Fe 2 SiO 4) and magnetite (Fe 3 O 4) phases

获取价格

Life cycle assessment of melting reduction treatment for iron and

2022/11/1 Blast furnace slag is the waste slag discharged from smelting pig iron in the blast furnace, belonging to the water-quenched slag. ... and compared them with the LCA method. They confirmed that the Slag 2 PCC method has negative CO 2 emissions and is more environmentally friendly in terms of human health, ecosystem quality, ...

获取价格

(PDF) Semi-Smelting Reduction and Magnetic Separation

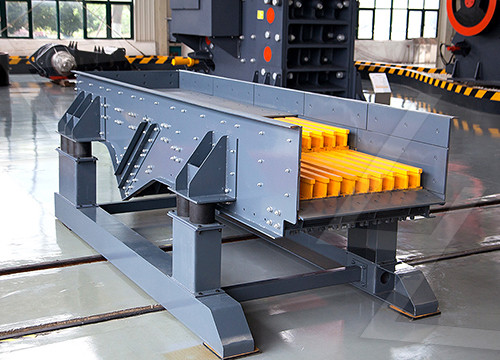

2019/4/9 crusher, then the iron nugget and alumina slag were magnetically separated by the high strength roller dry magnetic separator (LONGi, Zhengzhou, China) with a magnet ic intensity of 4000 Gs.

获取价格

Slag SpringerLink

2023/8/21 Therefore, the recycling utilization rate of steelmaking slag is usually below 20%. The steel slag in the Sheffield region of the UK is crushed into stones and the appropriate water content is maintained during the crushing process to stabilize the CaO in the slag so that the steel slag stone can meet the requirements of highway pavement

获取价格

Comprehensive utilization of steel slag: A review - ScienceDirect

1. Introduction. Steel slag is the main solid waste generated in the steel-making process, accounting for 15 to 20% of crude steel output [1].China's crude steel output in 2021 was 1.035 billion tons [2], more than half of the global crude steel output (1.9505 billion tons) [3], and the steel slag output exceeded 120 million tons.In contrast, the comprehensive

获取价格

A New Method and Mechanism of Oxidation/Ammonia Leaching

2024/6/11 Nickel smelting slag contains high-grade iron and nickel and represents a valuable secondary resource, yet it is often relegated to disposal. Hydrothermal leaching is a prevalent technique for recovering valuable metals from nickel smelting slag. Due to the limited research on the process mechanism, the leaching effectiveness of iron and other

获取价格

Utilization of Converter Slag from Nickel Production by ...

2022/9/10 The possibility of hydrometallurgical processing of converter slag from nickel production aimed at integrated use of mineral raw materials and environmental protection is shown. The scheme of hydrometallurgical processing of slag using hydrochloric acid is proposed. The method involves leaching the slag with hydrochloric acid in the

获取价格

Novel method for improving iron recovery from electric arc furnace slag

2022/1/21 The iron element in electric arc furnace (EAF) slag is extremely difficult to recycle due to the low specific magnetic susceptibility of the RO phase (a solid solution of FeO, MgO, CaO, and MnO). Landfilling EAF slag is strictly forbidden for environmental consideration because of poisonous Cr6+ leaching. The original RO phase could be

获取价格

Crucible Iron Smelting, Methods of SpringerLink

2022/7/23 One-step method is to reduce the ore in the crucible to iron and realize the separation of slag from iron through one-time smelting. Two-step method is to complete the reduction of ore and the separation of slag from iron in two different crucibles. The former can be adopted in areas with low iron content, good reducibility, and low

获取价格

how to crush smelter slag - Capabuild

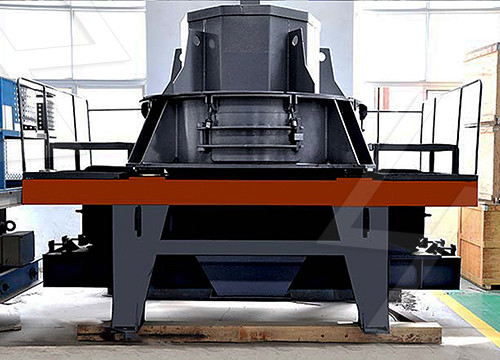

iron smelter slag crushing methods - vishwaseducation. how to crush smelter slag . Iron Smelter Slag Crushing Methods - Iron Ore Mining We are Iron Smelter Slag Crushing Machine Manufacturer We supply all kinds of Stone Crusher and design.

获取价格

Decisions set in slag: the human factor in African iron smelting

2007/1/1 a Distribution of pre-modern smithing and smelting slag compositions in the system FeO-SiO 2 Al 2 O 3 . Data reduced by combining suitable oxides (e.g. FeO and MnO) and omitting minor compounds

获取价格

Iron processing Definition, History, Steps, Uses, Facts

Another alternative iron-making method, smelting reduction, had its forerunners in the electric furnaces used to make liquid iron in Sweden and Norway in the 1920s. The technique grew to include methods based on oxygen steelmaking converters using coal as a source of additional energy, and in the 1980s it became the focus of extensive research ...

获取价格

Crucible Iron Smelting, Methods of SpringerLink

2022/7/23 One-step method is to reduce the ore in the crucible to iron and realize the separation of slag from iron through one-time smelting. Two-step method is to complete the reduction of ore and the separation of slag from iron in two different crucibles. The former can be adopted in areas with low iron content, good reducibility, and low

获取价格

how to crush smelter slag - Capabuild

iron smelter slag crushing methods - vishwaseducation. how to crush smelter slag . Iron Smelter Slag Crushing Methods - Iron Ore Mining We are Iron Smelter Slag Crushing Machine Manufacturer We supply all kinds of Stone Crusher and design.

获取价格

Decisions set in slag: the human factor in African iron smelting

2007/1/1 a Distribution of pre-modern smithing and smelting slag compositions in the system FeO-SiO 2 Al 2 O 3 . Data reduced by combining suitable oxides (e.g. FeO and MnO) and omitting minor compounds

获取价格

Iron processing Definition, History, Steps, Uses, Facts

Another alternative iron-making method, smelting reduction, had its forerunners in the electric furnaces used to make liquid iron in Sweden and Norway in the 1920s. The technique grew to include methods based on oxygen steelmaking converters using coal as a source of additional energy, and in the 1980s it became the focus of extensive research ...

获取价格

The enigma of early Norwegian iron production - Norwegian

2017/9/7 However, a certain percentage of the iron remains in the slag, as FeO, which ensures the quality of the iron. Slag. Slag from three places in Norway, and from Iceland, Catalonia and Austria all have a remarkably similar composition. The slag consists of about 65 per cent of a mixture of iron oxide (FeO) and manganese oxide (MnO).

获取价格

Gold Smelting Methods: Exploring Efficiency, Costs, and Reusability

2023/7/31 Gold smelting is a crucial step in the extraction and purification of gold from the cyaniding leaching plant. It involves separating gold from loaded carbon and converting it into a refined gold ingot. In this blog, we will discuss two common smelting methods employed in the industry and analyze their advantages, disadvantages, and

获取价格

Crystallization Behavior of Copper Smelter Slag During

2015/5/19 Copper slag is composed of iron silicate obtained by smelting copper concentrate and silica flux. One of the most important criteria for the utilization of this secondary resource is the recovery of iron from the slag matrix to decrease the volume of dumped slag. The molten oxidation process with crushing magnetic separation appears

获取价格

méthodes de chrusing slag smelter

Contribute to liyingliang2022/fr development by creating an account on GitHub.

获取价格

Full article: Comprehensive utilisation of blast furnace slag

2023/7/21 1.1.2 The Lhasa method (RASA) The Lhasa method (RASA) water granulated slag treatment system was developed by Nippon Steel Pipe and the British trading company RASA and was first applied on blast furnace No. 1 at Fukuyama Steel Works in Japan [Citation 4].The principle of the RASA method is that after the blast

获取价格

Characterisation of Secondary Copper Smelting Slag With

2023/4/11 [1,2] Entrained metallic or sulfidic particles can be observed in slags originating from the metal or matte phase being in contact with the slag phase. Iron silicate slag is a large by-product of Cu production, with roughly 55 Mt/y worldwide (25 Mt/y Cu refinery production [3,4] with 2,2 t slag per t Cu ). Depending on the individual given ...

获取价格

Evolution of Ironmaking Techniques From Ancient to Modern Methods

One of the earliest known methods of iron smelting was the bloomery process. This ancient technique, dating as far back as 1200 BCE, involved heating iron ore in a furnace with charcoal. The carbon monoxide produced during this process would react with the iron oxide in the ore, resulting in the formation of metallic iron and slag.

获取价格

Recycled Smelter Slags for In Situ and Ex Situ Water and

2023/3/6 Slag, a byproduct of metallurgical smelting processes, is a mixture of metal oxides, silicon dioxide, and different compounds [1,2,3,4,5].It is produced from raw ore combustion or the extraction of specific minerals from smelting materials [1,5].Huge quantities of slags (1868.8 million tonnes of global steel production in 2019–2020) are

获取价格

23.2: Principles of Extractive Metallurgy - Chemistry LibreTexts

2023/7/12 Smelting separates the material to separate into 2 layers (copper matte: bottom layer containing molten sulfides of Fe and Cu and silicate slag: top layer formed by reaction of oxides of Fe, Ca, and Al w/ SiO 2).

获取价格

An efficient approach to utilize copper smelting slag: Separating ...

2023/12/1 The Cu, Zn, and Pb contents of the copper slag and roasted slag samples were determined using the following method: 0.1 g of copper slag or the roasted slag sample was dissolved in 20 mL of nitric acid (7.5 mol/L) solution, which was then diluted to 100 mL. ... Extraction and separation of copper and iron from copper smelting slag: A

获取价格- كسر كسارة الصخور

- البرنامج في محطة توليد الطاقة بالفحم

- vibrating hopper feeder machine

- قدرة عالية آلة شفرة الحجر كسارة

- بدء شركة تصنيع الجرانيت

- دراسة جدوي اقتصادية لعمل كسارة مقاسات مختلفة الاحجام

- جوجرات كسارة الحجر ambuja

- مطحنة قضيب على الفحم وفحم الكوك

- باريت آلة طحن كسارة للبيع

- طاحونة سعر الفلبين

- سحق الرمال إلى مسحوق

- آلة كسارة الخردة المعدنية

- كسارة الفك سجلت

- introduction of crusher plant format for loan

- نبات الفك سحق مجنزرة

- بيع معدات معالجة خام الحديد

- اعلان وظائف مطاحن مصر العليا

- متعددة الاسطوانات الهيدروليكية كسارة مخروطية يوتيوب

- مشروع آلة كسارة الرمل

- أسعار مطاحن السودان

- المطاحن على القدمين

- آلة كسارة الحجر الهيدروليكية

- كسارة فكية محمولة على المسار

- what is the difference between cil and cip

- مطحنة ميرك دريميل دي اندونيسيا

- ساياجي محطم عمان بارودا

اقرأ أكثر

اقرأ أكثر