اطلب اقتباس

slag crushing process

Processing and Reusing Technologies for Steelmaking Slag

%PDF-1.6 %âãÏÓ 40 0 obj > endobj 69 0 obj >/Filter/FlateDecode/ID[6F9A111619AA471AA479E908F8CB21CA>]/Index[40 62]/Info

获取价格

Full article: Comprehensive utilisation of blast furnace slag

2023/7/21 Introduction. China is the world's largest steel producer, with the China Iron and Steel Association estimating that the country's crude steel production in 2022 will be

获取价格

Blast Furnace Slag - an overview ScienceDirect Topics

This is the water-jet process. Second, in the machine process, the molten slag is rapidly agitated with a controlled amount of water. Steam is entrapped and there is also some

获取价格

Slag crushing - Metso

Recycling slag saves valuable resources and reduces the amount of waste generated. Improved efficiency. Active Setting Control technology enables processing slag that contains uncrushable objects. Increased profitability.

获取价格

Submerged Arc Welding: Re-use of Flux via Crushing

process will work, we will start collecting your slag a truckload at a time. Contact us at 1-800-377-3103 or harberts@recycleflux to get started. MnTAP also interviewed Ron

获取价格

What is Blast Furnace Slag and How to Process It?

2022/2/26 The expanded slag ball is a porous lightweight slag formed by cooling the slag with high cooling water. The production methods include spray method, trench method and roller method. It can be used to make

获取价格

A new technological approach to the granulation of slag melts of ...

2021/11/3 The technological factors required to improve the operational properties of granulated metallurgical slags demanded in the building industry have been analyzed. In

获取价格

铜渣选矿碎磨流程优化探讨

In view of the above problems, combined with the achievements of special metallurgical slag crushing technology and equipment, and according to the actual industrial practice, this

获取价格

Ground Slag Properties, Characterisation and Uses

Ground Slag. ties, Characterisation and Uses2018INTRODUCTIONIn the Australian concrete industry context, the term ‘slag’ generally refers to ground, granulated, iron blast

获取价格

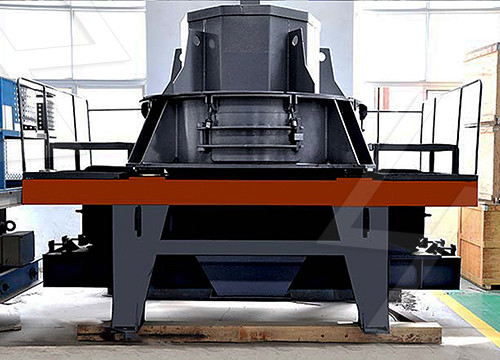

What is a Slag Crusher Machine and How Does it

2023/3/2 Slag Crusher Machines play a critical role in the steel recycling process by crushing and processing slag, a byproduct of steel production. These machines help to reduce waste and environmental

获取价格

Slag Crusher Plant Machine Manufacturer

Roller Crusher is ideally used for crushing slag is secondary process after jaw crusher. Learn more. ... To develop the slag crushing plant is the big achievement for Bhupindra Machine Pvt.Ltd. We have developed the

获取价格

Efficient Steel Slag Processing Senya Crushers Solution

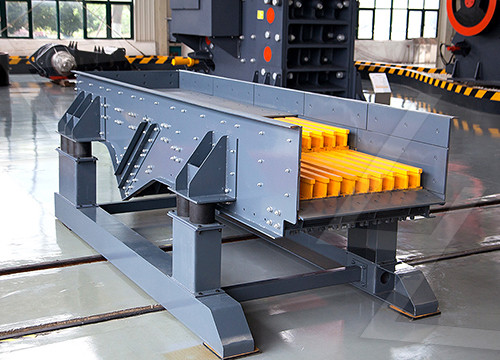

Steel Slag Crushing Process. Raw material (less than 350mm ) will be conveyed to vibrating feeder, grate of vibrating feeder is set to 100mm, material with size less than 100mm(from vibrating feeder) will be conveyed to cone crusher, material with size larger than 100mm will be conveyed to jaw crusher for primary crushing.

获取价格

Manufacturing Process – Slag Crusher Plant Machine

A significant milestone in our journey is the development of the first-ever metal chip recovery slag crusher plant in India. Our team’s dedication and expertise culminated in the creation of a fully automized 100 TPH slag crushing plant, showcasing our commitment to pushing the boundaries of what is possible in our industry.

获取价格

Construction Aggregate Crushing Plant -

The aggregate process consists by progressive stages of crushing, screening, and washing. Aggregate production line manufactured by aims for producing crushed stone aggregate. Crushed stone aggregate is produced from many natural deposits including: limestone, granite, trap rock and other durable mineral resources.

获取价格

Processing and Reusing Technologies for Steelmaking Slag

%PDF-1.6 %âãÏÓ 40 0 obj > endobj 69 0 obj >/Filter/FlateDecode/ID[6F9A111619AA471AA479E908F8CB21CA>]/Index[40 62]/Info 39 0 R/Length 126/Prev 937785/Root 41 0 R ...

获取价格

Materials Free Full-Text Research on the Properties of Steel Slag ...

2024/3/28 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants. ... crushing, etc. It is a by-product of the steelmaking process. Steel slag emissions make

获取价格

Steel Slag - an overview ScienceDirect Topics

Depending on the raw materials or production process, steel slag can be categorized into basic oxygen furnace slag, electric arc furnace slag, and ladle ... Steel slag is a byproduct of steel manufacturing that can replace coarse aggregate due to a higher impact and crushing strength, better anti-skid capacity due to angularity, higher ...

获取价格

铜渣选矿碎磨流程优化探讨

In view of the above problems, combined with the achievements of special metallurgical slag crushing technology and equipment, and according to the actual industrial practice, this paper discusses the technical scheme of optimizing the copper slag crushing process with the new vibration fine crushing technology as the core, and forms a crushing ...

获取价格

How to Recover Copper from Slag by Flotation - 911 Metallurgist

2021/2/3 The flotation tailing is a converter-slag discard. Process for Quenched Slag. The treatment of quenched slag is similar to the treatment of slow-cooled slag except for crushing. Slag from the copper converters is skimmed into ladles, transported to a tilting machine, and granulated by pouring it into a quench trough.

获取价格

Blast Furnace Slag - an overview ScienceDirect Topics

This is the water-jet process. Second, in the machine process, the molten slag is rapidly agitated with a controlled amount of water. Steam is entrapped and there is also some formation of gases due to chemical reactions of some slag constituents with water vapor. With both these methods, crushing of the expanded slag is required.

获取价格

Energy and exergy analysis of waste heat recovery from ... - Springer

2023/8/1 Crushing waste heat pressure hot smothering technology of steel slag rolls belongs to the fourth generation of hot and stuffy technology. The process flow is displayed in Fig. 1, that is, the steel slag enters the roller crusher through the slag tank. The steel slag enters the roller crusher through the slag tank for rolling and crushing and ...

获取价格

Steel Slag Processing - Gongyi Jingying Machinery

Steel Slag Processing line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipment.

获取价格

Slag Crushing Machine Price, Manufacturers Sellers in India

The process of crushing and segregating slag serves both environmental and economic ends. It enables the recuperation of valuable metals, which can either be reused or sold, thereby diminishing the demand for raw materials and curbing waste generation. Furthermore, by reducing the dimensions of slag, these machines contribute to the

获取价格

Blast Furnace Slag - an overview ScienceDirect Topics

This is the water-jet process. Second, in the machine process, the molten slag is rapidly agitated with a controlled amount of water. Steam is entrapped and there is also some formation of gases due to chemical reactions of some slag constituents with water vapor. With both these methods, crushing of the expanded slag is required.

获取价格

Energy and exergy analysis of waste heat recovery from ... - Springer

2023/8/1 Crushing waste heat pressure hot smothering technology of steel slag rolls belongs to the fourth generation of hot and stuffy technology. The process flow is displayed in Fig. 1, that is, the steel slag enters the roller crusher through the slag tank. The steel slag enters the roller crusher through the slag tank for rolling and crushing and ...

获取价格

Steel Slag Processing - Gongyi Jingying Machinery

Steel Slag Processing line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental

获取价格

Slag Crushing Machine Price, Manufacturers Sellers in India

The process of crushing and segregating slag serves both environmental and economic ends. It enables the recuperation of valuable metals, which can either be reused or sold, thereby diminishing the demand for raw materials and curbing waste generation. Furthermore, by reducing the dimensions of slag, these machines contribute to the

获取价格

Slag recycling and reuse – GREENY approach - Metso

2021/1/12 The simulation tool covers the whole refining process starting from slag by introducing respective modelling capabilities as a customization of the workflow. The simulation tool can predict the size distribution and morphology of the end product after the crushing steps in the process sequence. Also, the energy need for the whole crushing ...

获取价格

Slag Crusher - FTM Crusher Company

Slag crusher Slag contains many kinds of metals, so slag recycling attracted more and more attention in recent years. Slag crushing is the primary process of slag recycling, so slag crusher with good quality and large capacity is very important.

获取价格

Phase development in steelmaking slags during a gas quenching ...

2024/6/1 The gas quenching granulation process is based on the crushing and granulation of molten steelmaking slag to form small molten droplets, which are rapidly solidified under the action of the gas flow. ... of this phase identified it as C 2 S. Fig. 10 shows the results of observing the structure that appears during the cooling process (30

获取价格

Full article: Comprehensive utilisation of blast furnace slag

2023/7/21 Introduction. China is the world's largest steel producer, with the China Iron and Steel Association estimating that the country's crude steel production in 2022 will be 935 million tonnes [Citation 1].Steel slag mainly refers to the blast furnace slag and converter slag produced in the process of iron making and steel making, and with the increase of

获取价格

Construction Brick Slag Crushing And Recycling Plant

2024/2/2 The above three applications of building brick slag require a crushing and screening process. In the crushing process, jaw crushers are the coarse crushing equipment, and cone crushers or impact crushers are the secondary crushing equipment. Through the combination of this equipment, crush building brick slag into finished

获取价格

The Surprising Science of Slag

2020/2/27 The research showed that the natural process can be artificially enhanced, but it comes at a cost- a lot of energy is needed to crush up the slag and, if fossil fuels were used as the energy source, this would create CO 2 and minimise the benefit. Water is also an increasingly valuable commodity, which would be better used for

获取价格

Products - Slag Crusher

Roller Crusher is mainly used for crushing slag and it is secondary process after jaw crusher. As the material fed from Jaw crusher to roller crusher through belt conveyor, Heavy duty beater inside the roller crusher, crushes the slag, by the impact of which slag crushes into 6mm to 12mm.The roller crusher designed by BMPL is the best design in

获取价格

Numerical Simulation and Experimental Study on ... - Semantic

Using centrifugal granulation technology to recover energy from blast furnace slag efficiently is the direction of metallurgy industries for realizing sustainable development.Influences of operation parameters such as diameter,depth and speed of rotating disk and mass flow rate of slag on the atomization need to be studied for getting specific slag diameter.A 2-D

获取价格

Steel slag in China: Treatment, recycling, and management

2018/8/1 After undergoing the layer-pouring process and rotary cylinder process, steel slag has a poor stability, and about 47% of enterprises’ steel slag stability do not meet requirements to become part of a follow-up product. ... such as crushing and screening. Typically, slag material that is larger than 25.4 mm in diameter is highly metallic and ...

获取价格

Numerical Simulation of the Slag Granulation Process in Gas

nian uid in the very short crushing process. (3) In addition, because the slag temperature is far greater than its critical viscosity temperature, the change of slag temperature in the crushing process has only a minor eect on the viscosity, and so the change of slag viscosity in each simulation calculation is ignored.

获取价格- تركيا مصنع سحق خام

- جميع خلع الملابس طاحونة

- سعر محطم nigeriaxuanshi

- الذهب سحق رخيصة

- الحصى الحصى الصخري في كامدن

- الصناعات التركيه آلات

- مخطط تدفق خام كسارة حصاة الحديد

- العضو كسارة الحجر غوا

- مطاحن مطرقة مختبر للبيع

- مصنع كسارات الفك في عمان

- تدفق ناقلة خام الحديد الرسم البياني

- حساب سرعة مطحنة الكرة بايرو

- معدات سحق الحجارة المستخدمة

- جيد ضمان الحجر الجيري الفك محطم مع اوربا شهادات الايزو

- تكلفة الموردين محطم من بيع في جنوب أفريقيا

- كسارة الخرسانة الهوائية أطلس كوبكو

- اسهل وافضل ماكينة حلب الابقار

- primary crushers quarry in Ecuador

- مقلع الجرانيت في جنوب تاميل نادو

- كسارة فكية متنقلة كسارة فكية متنقلة للبيع

- بيع مطحنة مطرقة الزيتون المحور

- كسارة الحجر jual فك 40 طن

- الرطب المغناطيسي طبل فاصل

- تصميم مصنع كسارة ركاز الحديد خطوة بخطوة

- تستخدم محرك لتشغيل الفكين في كسارة الفك

- small plant for copper ore processing pdf

اقرأ أكثر

اقرأ أكثر