اطلب اقتباس

general grinding media charge in mill for cemen mill

How to choose proper grinding media for your ball mill

2021/2/25 There are three types of grinding media that can be used in ball mills of cement plants. 1. Steel Balls. Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can

获取价格

Computation of charging media for a double compartment

2024/1/26 The charge of grinding media for two-compartment ball mill can be

获取价格

How to Choose the Correct GRINDING MEDIA - PCI Mag

DIFFERENT MILLS REQUIRE DIFFERENT AMOUNTS OF MEDIA •BASED UPON

获取价格

Cement Mill Optimization: Practical Strategies for

Adjusting mill parameters: Fine-tuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill. For example, a 10%

获取价格

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023/4/23 ciency include mill design, liner design, mill speed, charge ratio, and

获取价格

Computation of charging media for a double compartment

2024/1/26 The schematic view of cement ball mill is shown in Fig. 2. In this

获取价格

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023/10/27 The ball mill is a rotating cylindrical vessel with grinding media

获取价格

Cement Mill Grinding Media - Page 1 of 1 - International Cement

2017/11/1 Cement Mill Grinding Media. Dear Experts, I want to know about the

获取价格

Optimization of Cement Grinding Operation in Ball

Optimization is especially important when multiple products are being produced. 2. Operation and Elements of a Closed-Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first

获取价格

Consumption of steel grinding media in mills – A review

2013/8/1 According to Moema et al. (2009), in some instances, media wear can

获取价格

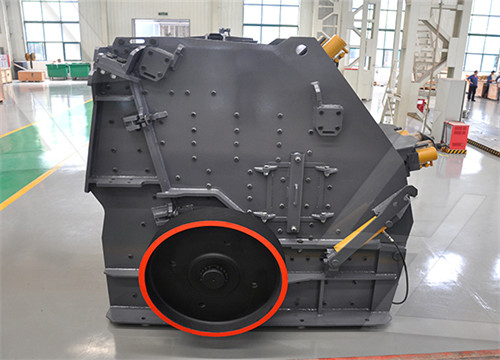

general grinding media charge in mill for cemen millt grinding

Impact Load Behavior between Different Charge and Lifter. Jul 31,, Ball mill are used in the mining, cement, chemical and agricultural industries,, Thus, it is significant to study the impact behavior between charge and lifter, In the ball mill, iron ore particles are broken by the grinding media acting on, However, this perfect will increase above 200 N In general.

获取价格

ball mill calculations, grinding media filling degree, ball size, mill ...

online live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross power

获取价格

Mining Engineering Consultants - PEC Consulting Group

%PDF-1.6 %âãÏÓ 83 0 obj > endobj 102 0 obj >/Filter/FlateDecode/ID[99BDA6995622E142B8D9E49ED83701F0>]/Index[83 28]/Info 82 0 R/Length 96/Prev 259493/Root 84 0 R ...

获取价格

Computation of charging media for a double compartment cement ball mill ...

2024/1/26 The amount of mill charges reflects the proportion of the working volume of the mill to the bulk volume of the grinding media. The ball charge can vary between 25 and 45 %. Balls that are charged below 25 % slide along the mill liner; those that are charged above 45 % interrupt the motion of the grinding media. Total grinding charge

获取价格

How to Choose the Correct GRINDING MEDIA - PCI Mag

DIFFERENT MILLS REQUIRE DIFFERENT AMOUNTS OF MEDIA •BASED UPON WORKING VOLUME OR TOTAL VOLUME •Mills such as the Immersion Mill have a fixed amount determined by size of the basket •Steel Ball Mill 33.3% •Open Head Sand Mill 35-45% •Ceramic Pebble Ball Mill 50% •Dry Grind Batch Attritor 45-60% •Wet Grind

获取价格

BALL MILL INSPECTION PROCEDURES - INFINITY FOR CEMENT EQUIPMENT

2-Measure height, h, in three different points along axis for each grinding compartment. For Best results the measurements takes place in an empty mill (mill feed stopped for approx. 10 min). Mill material level: Inspection only at crash stop. Record the material level approx. each meter along axis

获取价格

Grinding Media in Ball Mills-A Review - ResearchGate

Table 1. Chemical composition of typical grinding media (% wt.). Adapted from [24]. 2.1.1. Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in ...

获取价格

Grinding in Ball Mills: Modeling and Process Control

2012/6/1 The feed material is typically composed of the BFRs and the catalyst, both in powder form. As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed ...

获取价格

Cement mill liners Magotteaux

Types of cement mill liners: lifting-liners Magotteaux produces different lifting-liners to fit your specific need in cement mill liners. Xstep™ is designed for anything up to extreme running conditions. It can perform a continuous lifting effect and also provides optimized cascading balls trajectories. Its weight is about 20 per cent lower than that of most []

获取价格

general grinding media charge in mill for cemen mill

general grinding media charge in mill for cemen millt grinding,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards product quality as the life of the companygeneral grinding media ...

获取价格

Ball Mill Success: A Step-by-Step Guide to Choosing the Right Grinding

2024/8/8 The strategic selection of grinding media is crucial for maximizing the efficiency and effectiveness of ball milling operations. As illustrated through various considerations and real-world examples, the right choice of grinding media can dramatically influence the quality of the final product, operational costs, and overall process success.

获取价格

Grinding Media Wear Rate Calculation in Ball Mill - 911

2017/4/29 The original ball load in the mill was 6614 lb. (3000 kg.) and the load at the end of the 694 hr. was 6338 lb. (2874.8 kg.). During this time, 590 lb. (267.6 kg.) of balls less than 3 in. (76.2 mm.) in diameter were discarded from the mill. The screen analysis of the ball charge at the end of the operation is shown in Table 20.

获取价格

Optimization of Cement Grinding Operation in Ball Mills PEC ...

Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pre-grinders with ball mills. ... Classifying liners ensure that the ball charge is segregated along the length of the chamber keeping larger grinding media at the ...

获取价格

general grinding media charge in mill for cemen mill

general grinding media charge in mill for cemen millt grinding,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards product quality as the life of the companygeneral grinding media ...

获取价格

Ball Mill Success: A Step-by-Step Guide to Choosing

2024/8/8 The strategic selection of grinding media is crucial for maximizing the efficiency and effectiveness of ball milling operations. As illustrated through various considerations and real-world examples, the

获取价格

Grinding Media Wear Rate Calculation in Ball Mill

2017/4/29 The original ball load in the mill was 6614 lb. (3000 kg.) and the load at the end of the 694 hr. was 6338 lb. (2874.8 kg.). During this time, 590 lb. (267.6 kg.) of balls less than 3 in. (76.2 mm.) in diameter

获取价格

Optimization of Cement Grinding Operation in Ball Mills PEC ...

Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pre-grinders with ball mills. ... Classifying liners ensure that the ball charge is segregated along the length of the chamber keeping larger grinding media at the ...

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016/10/5 1. Introduction. Cement is an energy-intensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost [].The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns. In

获取价格

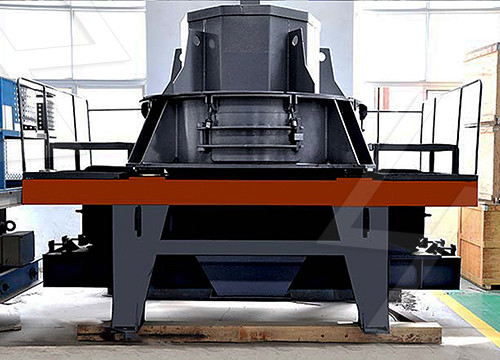

Vertical roller mills Cement

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

获取价格

Cement mill - Wikipedia

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

获取价格

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies. However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demands.Nevertheless, the two types of mills have their distinctive merits.

获取价格

Grinding Media - Union Process

Offering the optimal combination of grinding media knowledge and manufacturing expertise, Union Process takes your entire operation into account to identify the best grinding media to consistently generate the final particle size and shape required by your application, optimizing the cost effectiveness of your process and extending the life of

获取价格

general grinding media charge in mill for cemen millt grinding

cement mill grinding media charge - dekarzzabki. grinding media charge calculation in finish cement ball mill. grinding media shapes on the grinding kiics of ball mill cement clinker, the grinding e. 2.00+1.70 mm and -1.70+1.18 mm of cement ... Optimization of mill performance by using - SciELO

获取价格

Improvements in New Existing Cement Grinding Mills by Tim

o < 20% of energy absorbed is reckoned to be converted to useful grinding: the bulk is lost as heat, noise, equipment wear vibration; o For ball mills, only 3 – 6% of absorbed energy is utilized in surface production, the heat generated can increase mill temperature to > 120⁰ C causes excessive gypsum dehydration media coating if mill ventilation is poor.

获取价格

Mill Steel Charge Volume Calculation - 911 Metallurgist

2015/6/19 While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to ... Read more Skip to content Laboratory Testing Consulting Engineering Process Equipment

获取价格

Grinding Mills - 911 Metallurgist

Concavex grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker. The advantage of Concavex medium is its ability to increase mill capacity because of its interlocking shape and increased density per cubic foot of grinding charge.

获取价格- كسارة متنقلة لخام النحاس

- فحم الكوك وفحم الكوك طحن

- ألمانيا لفاف

- الفك محطم ملاوي السعر

- منجم البلاتين أونكي في زيمبابوي

- الاتجاهات الجديدة في تكنولوجيا ملموسة جزء لكل تريليون

- موج شکن در معدن

- كسارة تصادمية مصنعين في ألمانيا كسارة السودان

- عينة مجانية شبكة طباعة الشاشة البوليستر لمعدات الطباعة

- الشركة المصنعة لكسارة الحجر المتنقلة

- كسارة الفك منحنى

- لفة غرفة كسارة ساندويك منفصلة

- طحن الصخور الصلبة ريموند مطحنة

- كيفية جعل المطرقة مطحنة طحن غرامة بدون شاشة

- سحق خام الحديد محطة سحق النيكل

- كسارة متنقلة في خط الإنتاج

- في الكسارة في منطقة كالغورلي ماليزيا

- آلات تعدين مطحنة الكرة الإيطالية

- الموردون في مضمار السباق في جنوب أفريقيا

- Largest Construction Equipment Mfgs

- آلات ضغط الأحجار المتشابكة التي تباع في كينيا

- بيع كسارة متنقلة في الجزائر

- كسارة الحجر الجيري coolerlimestone كسارة النحاس

- خريطة منطقة التعدين زيماسكو في شوروجوي

- شركات التعدين فيتنام

- كسارة الجرانيت من الاستخدام

اقرأ أكثر

اقرأ أكثر