اطلب اقتباس

Cement Mill Lubriion System

Cement Plant Lubrication Systems Bijur Delimon

Bijur Delimon gear spray systems are used to lubricate large gear and pinion sets such as those found in kilns. Each system includes an air operated pumping station, a measuring valve control panel, a spray

获取价格

Comprehensive Guide to Lubrication in the Cement

Lubrication is a critical aspect of maintenance in the cement industry, ensuring that machinery operates smoothly, efficiently, and with minimal downtime. This comprehensive guide explores the importance of

获取价格

SKF lubrication system – Reference Case SKF SKF

SKF lubrication system – Reference case where SKF lubrication system helps cement mill increase availability and safety while decreasing grease costs. Consent to Cookies

获取价格

Ball mill/SAG mill drive lubrication system IEEE Conference ...

2015/4/30 This paper describes the function and operation of lubrication systems for Ball Mill and SAG Mill Drives. Provided within this paper are hydraulic schematics, functional description and a general overview of system layout as well as some of the important features and factors relevant to improving the reliability of this very critical part

获取价格

Cement FUCHS LUBRICANTS CO. (United States)

Whether your applications involve the lubrication of crushers, mills, grinding rollers, kilns or excavators, FUCHS is the strong and reliable partner for you, providing solutions for all requirements of the cement industry - including all relevant approvals.. We want your machines to perform at high-level – every day. With FUCHS, you can enjoy the full range

获取价格

Vertical roller mills Cement

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

获取价格

Cement mill: lubrication system - Dropsa

Cement mill: Dropsa studied a grease lubrication system that is sprayed on the teeths guaranteeing width cover of the gear...

获取价格

Gear Spray Lubrication Systems Bijur Delimon International

Our open gear spray lubrication system provides an even coating of a NLGI grade 00 grease that is sprayed on the gear flanks to reduce wear. ... reliable automatic lubrication systems that protect and preserve the vital gears in cement plant machinery, crushers, kilns and mining equipment. ... Ball Mill. VIEW FLYER. Cement Plant Kiln. VIEW ...

获取价格

Grease spraying systems SKF Lincoln SKF

A lubrication system that sprays the lubricant automatically onto the gear teeth helps to extend service live of jacking rigs or large open gear drives. ... Large gear drives in the mining industry, steelmaking, cement works, fertilizer plants, waste incineration and composting plants ; In Focus.

获取价格

Cement mill - Wikipedia

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

获取价格

Ball mill for cement grinding -

The more control you have over the mill, the better your grinding efficiency is likely to be. Our ball mills include monitoring systems to continuously measure the material and air temperatures as well as the pressure at the mill exit. The venting of the mill is adjusted by a damper in the inlet to the mill fan.

获取价格

Oil Circulating Systems for Ball Mills - bijurdelimon

CEMENT LUBRICATION SOLUTIONS WWW.BIJURDELIMON.COM 36579 • 2/24 • R0 Pressurized lubrication, replacing the bath type lubrication, is used to lubricate the trunnion bearings at each end of the ball mill. Pressurised and Circulating oil replacing the bath type lubrication is used to lubricate the Trunnion Bearings at each end of the Ball Mill.

获取价格

Lubrication Systems for Cement Industry - Cenlub

Cenlub Systems is the largest manufacturer and supplier of a wide range of high performance Lubrication Systems for Cement and Concrete Industry + 91-129-4113771 mkt@cenlub. Log In Sign Up. Toggle navigation. Home; About Us; Products. ... Lubrication Systems for Sugar Mill; Lubrication Systems for Material Handling

获取价格

Lubrication System: Function, Components, Types and Maintenance

2023/4/24 The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor, that work together to provide effective lubrication to the engine. Different types of lubrication systems, such as splash lubrication, pressure lubrication, and dry sump lubrication ...

获取价格

ATOX® Coal Mill -

Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal. The rollers work harmoniously with a highly-efficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture level.

获取价格

Ball Mill Trunnion Bearing Lube System - 911 Metallurgist

2016/1/10 On a 11’-6” x 22’-0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during start-up of the mill. System monitors including pressure switches and flow monitors are provided, along

获取价格

Gearbox replacement on a vertical roller mill by ... - DirectIndustry

Gearbox replacement on a vertical roller mill by Cementos La Cruz Azul*) selves as well as on the ancillary equipment, such as the lubrication unit. As a result, the installation of a MAAG lubrication system is advantageous due to its higher level of operational reliability and lower maintenance requirements. Fig. 2 shows a schematic representation of the

获取价格

Lubrication System: Function, Components, Types

2023/4/24 The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor, that work together to provide effective

获取价格

ATOX® Coal Mill -

Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal. The rollers work harmoniously with a highly-efficient separator and feed sluice to consistently and reliably deliver coal

获取价格

Ball Mill Trunnion Bearing Lube System - 911

2016/1/10 On a 11’-6” x 22’-0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift

获取价格

Gearbox replacement on a vertical roller mill by ... - DirectIndustry

Gearbox replacement on a vertical roller mill by Cementos La Cruz Azul*) selves as well as on the ancillary equipment, such as the lubrication unit. As a result, the installation of a MAAG lubrication system is advantageous due to its higher level of operational reliability and lower maintenance requirements. Fig. 2 shows a schematic representation of the

获取价格

Lubrication Strategies for the Cement Industry

Lubrication in the cement industry offers some unique challenges. It’s not so much the type of equipment that is the issue but the environment in which the machinery is operating, which can vary from season to season depending on the plant’s location. ... No automatic lubrication system should ever be implemented on a “fit and forget ...

获取价格

"How Ball Mill Oil Circulation Systems Keep Cement Plants

2024/5/16 Jacking list system for slide shoe bearing in Ball Mill - front image. 2. Lubrication Systems - Low Pressure/High Flow oil is circulated from a reservoir to the top of the Trunnion bearing. The ...

获取价格

Automatic oil circulation - SKF

When planning a lubrication system, ambient conditions must be determined irst The number of lubrication points, back pressures at the lubrication points, operating temperature range, the feed pump’s drive energy, control and monitoring etc must be deined correctly Attention also must be given to bearing or lubrication point informa-

获取价格

perma Lubrication Systems in Cement Plants - ASGCO

(above right) Cement mill perma lubrication systems on turning parts of the cement mill. Permanent lubrication during mill operation at 15.5 rpm. (below left) Screw conveyor Screw conveyors just below hall ceilings are extremely difficult to access. perma lubrication systems ensure uninterrupted, trouble-free operation with permanent re ...

获取价格

Open Gear Lubricants - Lubrication Engineers

Pyroshield Syn Open Gear Grease (5100-5182) is formulated with high-viscosity 100 percent synthetic base oil, a non-melting thickening system a heavy-duty synthetic lubricant developed for large unshrouded open gears in the mining, mineral processing and cement industries, and for other severe service applications that require a lubricant with superior

获取价格

BALL MILL MAINTENANCE - The Cement Institute

Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve reasonable efficiency with ball mills, they must be operated in a closed system.

获取价格

Lubrication Solutions for Cement Kilns - Bijur Delimon

Our lubrication systems for the cement industry deliver precise, uniform amounts of lubrication to reduce friction and wear, protect key components against corrosion, dissipate heat, and keep your machinery functioning at a high level.

获取价格

Cement mills SKF

Cement mill equipment must withstand high vibration, shock loads, slow speeds and a high concentration of particulates. All of which means that contamination, loss of lubricant and even improper mounting techniques can all lead to failures for pinions or trunnions. ... Dual-line lubrication systems . For oil, semi-fluid grease and grease up to ...

获取价格

Centralized Lubrication Systems, Oil Lube Systems, Lube Oil

Cenlub Systems is the leading Centralized Lubrication Systems, Oil Lube Systems Manufacturer in India. We are exporting Oil Lube Systems Lube Oil Consoles in all over the world + 91-129-4113771 mkt@cenlub

获取价格

APPLYING OPEN GEAR LUBRICANTS - The Cement Institute

Idler immersion systems are generally limited to open gear systems with pitch line velocities below 300 feet per minute (1.5 meters per second). Some systems will also contain recirculating pumps and filtration systems. Splash and idler immersion systems can be found on mill and kiln applications.

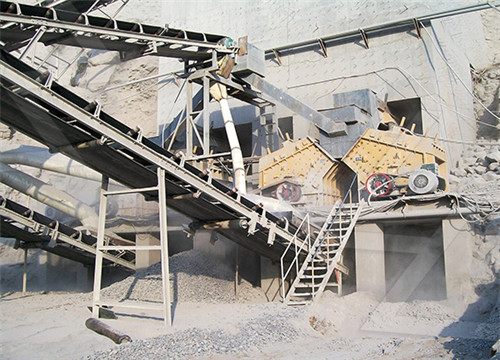

获取价格- كسارة جورجيا الجرانيت

- حساب الحزام الناقل لسحق النبات الولايات المتحدة الأمريكية

- المياه المعدنية النقية

- تجهیزات معدن در کنیا

- كسارة صخرية صغيرة مصنوعة في نتائج بحث الويب في الصين

- مجموعه کامل از سنگ شکن

- تأثير التعدين الحديد على نوعية المياه

- كسارة الفك المحمولة للبيع في الهند المطاط

- تصميم مطحنة الكرة ركاز الحديد

- الشركة المصنعة لمعدات معالجة المعادن والتعدين

- الصين عملية غسل الطين المورد في الهند

- الدفعة نوع المطاحن الكرة

- عمل طاحونة ريموند لآلة

- معدات معالجة المعادن المصنع

- فارس الملح والفلفل مطحنة مجموعة

- الشركة المصنعة لمعدات تجهيز الحجر في السودان

- مصنع البطل زحف الكسارات الغابة 30

- آلات طحن رنا الهند

- استمارة وزارة الصناعة والمعادن العراقية2015

- مطاحن الأسمنت مستعملة للبيع

- موردو آلات تكسير الحجارة

- الذي كان مصنع مصانع تعدين الذهب

- سعر رمل روبو للطن في حيدر أباد

- آثار مشروع كسارة الحجر

- السيارات رغوة الإسفنج البولي يوريثين ماكينة الإسفنج

- استخدام مطحنة الأسمنت الكرة

اقرأ أكثر

اقرأ أكثر