اطلب اقتباس

grinding roller encyclopedia

Roller Mill SpringerLink

2023/7/4 16 Accesses. Download reference work entry PDF. Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling

获取价格

Advances in grinding technology in China with

2020/6/17 Grinding of large or ultralarge components to achieve stringent quality is always challenging in China’s manufacturing industry,

获取价格

Vertical roller mill - Wikipedia

The vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the benefits of simple structure and low cost of manufacture and use. Vertical roller mills have many different forms, but they work basically the same. All of these forms come with a roller (or the equivalent of roller grinding parts), and roller along the track of the disc at the

获取价格

Roller mill - Wikipedia

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional millstone arrangements in gristmills. Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling.

获取价格

Grinding Equipment SpringerLink

2024/1/1 Grinding Equipment. Grinding equipment is a type of mineral processing equipment that further reduces the ore particle size of crushed massive or granular ore to

获取价格

Analysis and Optimization of Grinding Performance of

2022/1/23 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the

获取价格

Grinding (abrasive cutting) - Wikipedia

Grinding is a subset of cutting, as grinding is a true metal-cutting process. Each grain of abrasive functions as a microscopic single-point cutting edge (although of high negative

获取价格

三辊研磨机 研磨与分散 布勒集团 - GROUP

我们的三辊研磨机具有可靠、高产量以及对污染物和温度敏感物料柔和分散等突出特性,帮助您实现高质量研磨和分散。. 我们的研磨机提供各种磨辊材料和方案,满足清洁生产到国

获取价格

Machines Free Full-Text Effect of the Bionic Transverse ... - MDPI

2023/2/6 Chen T, Wang L, Xu J, Qin X, Dong X, Wang Q, Qi Y, Jin J, Cong Q, Liu C. Effect of the Bionic Transverse Stripe on Wear Resistance and Crushing Performance of

获取价格

Mill (grinding) - Wikipedia

Mill (grinding) A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is

获取价格

Grinding - ScienceDirect

1991/1/1 The most widely used types are disk and bowl mills in which the bowl-shaped grinding tracks are driven and the roller bodies roll in a fixed position. The oldest design of roller mill is the edge runner mill which is in widespread use in the ceramics industry both as a grinding unit and as a mixing unit. ... Ullmann's Encyclopedia of

获取价格

Energy-Efficient Technologies in Cement Grinding

2016/10/5 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over

获取价格

CNC Roll Grinding Machines Roll Grinding Machine

Robbi Roll Grinders: CNC machines for precision grinding of carbon fiber, rubber, ceramic, and more. Models: MSG 60 80. Maximum lengths: 3-10 meters.

获取价格

Creep Feed Grinding SpringerLink

2019/1/1 Various standards define creep feed grinding as a peripheral grinding process with a relatively large depth of cut a e and accordingly low feed rate v f (ISO 3002-5 1989; VDI 3390 2014; VDI 3391 2016).Commonly, surface grinding is referred to as creep feed grinding when depth of cut a e ≥0.1 mm and a feed rate v f ≤3,000 mm/min are

获取价格

Roller mill - Wikipedia

An early 20th-century oil-seed roller-mill from the Olsztyn district, Poland A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022 Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York Cutaway drawing of a centrifugal roller mill for mining applications, 1913. Roller mills are mills that use

获取价格

Vertical roller mill - Wikipedia

Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator

获取价格

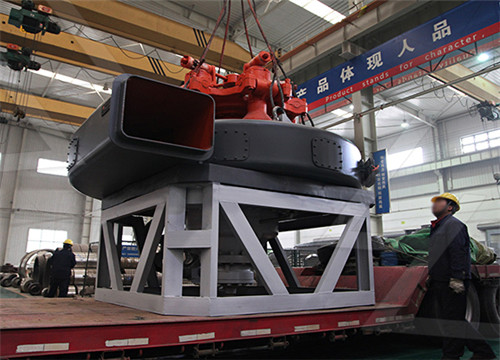

Grinding Roller Manufacturer From China - Symmen Metal

Grinding rollers produced by SYMMEN METAL Casting have features of high hardness, good anti-cracking and strong wear-resistant capability. We promise that, all the grinding rollers shall be NDT inspected on the stress surface through routing testing methods to ensure that each grinding roller is qualified before leaving our factory.

获取价格

Grinding Machines SpringerLink

2019/1/1 As grinding machines belong to the class of machines for the material removal with geometrically non-defined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically non-defined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 8589-11 2003;

获取价格

Grinding dresser - Wikipedia

A grinding dresser or wheel dresser is a tool to dress (slightly trim) the surface of a grinding wheel.Grinding dressers are used to return a wheel to its original round shape (to true it up), to expose fresh grains for renewed cutting action (including cleaning away clogged areas), or to make a different profile (cross-sectional shape) on the wheel's edge.

获取价格

Size Reduction – Visual Encyclopedia of Chemical Engineering

In ring-roller mills rollers feed solid coarse particles against a stationary grinding ring. The particles are broken apart by the resulting compression forces. Equipment Design. In a ring-roller mill, the material to be milled is fed into the grinding section. The moving roller forces the coarse material against the stationary grinding ring.

获取价格

Precision Roll Grinding Services Rol-Tec, Inc

Surface Grinding and Centerless Grinding. Our surface grinding applications include top and bottom tight tolerance grinding. We can perform surface grinding to 36" by 48". The Blanchard grinder can handle material up to 60" corner to corner. Our centerless grinding machines can precision grind parts up to 4.5" diameter by 48" long.

获取价格

14 Types of Grinding Machines [Working, Diagram PDF] - The

2021/11/23 These grinders are used for grinding round and hollow jobs whether the internal surface of this job is completely round, ditched round, or is in taper. Small grinding wheels of 3 cm to 5 cm, are used in such grinders. Sometimes grinding wheels of special shape 0.2 cm to 0.3 cm. These grinders can be divided into two parts. a. Chucking Grinder

获取价格

Grinding Machines SpringerLink

2015/1/1 As grinding machines belong to the class of machines for the material removal with geometrically non-defined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically non-defined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 8589-11 2003;

获取价格

Ambient, 3D Hot Roll Grinding Precision Roll Grinders

2021/8/30 Surface — grind (cold or hot grinding methods) rechrome and patch-plate repair roll surfaces as required; carbide recoating option available for longer life between regrinds Journals — complete repairs available from brush grinding and chrome and nickel plating to replacement of inner race, or other components as required; future journal ...

获取价格

Precision Roll Grinding Services Rol-Tec, Inc

Surface Grinding and Centerless Grinding. Our surface grinding applications include top and bottom tight tolerance grinding. We can perform surface grinding to 36" by 48". The Blanchard grinder can

获取价格

14 Types of Grinding Machines [Working, Diagram

2021/11/23 These grinders are used for grinding round and hollow jobs whether the internal surface of this job is completely round, ditched round, or is in taper. Small grinding wheels of 3 cm to 5 cm, are used in

获取价格

Grinding Machines SpringerLink

2015/1/1 As grinding machines belong to the class of machines for the material removal with geometrically non-defined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically non-defined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 8589-11 2003;

获取价格

Ambient, 3D Hot Roll Grinding Precision Roll Grinders

2021/8/30 Surface — grind (cold or hot grinding methods) rechrome and patch-plate repair roll surfaces as required; carbide recoating option available for longer life between regrinds Journals — complete repairs available from brush grinding and chrome and nickel plating to replacement of inner race, or other components as required; future journal ...

获取价格

Hot Lubrication Rolling SpringerLink

2023/6/22 Hot lubrication rolling is the technology that brings lubricant into the rolling deformation zone in a specific way. By using lubrication rolling, a layer of rolling lubricating oil film can be formed between the roll and the rolled piece, which changes the traditional “metal to metal” direct contact mode between the roll and the rolled piece.

获取价格

(PDF) Principles of Modern Grinding Technology - ResearchGate

2013/1/1 Superb grinding machines now produce optical quality finishes due to developments in process control and machine design. It is the same for extremely high removal rates. This book shows how best ...

获取价格

Grinding Machine: Parts, Working, Operations, More [PDF]

2023/3/9 If the dulled grains stay in the wheel, they keep on rubbing on work without actually cutting. This defect is known as ‘glazing.’ If, on the other hand, the abrasive grains break away from the wheel or split prematurely, before becoming dull, it causes a reduction in life of the grinding wheel. Selection of Abrasives in Grinding

获取价格

Micromachines Free Full-Text Investigation on the ... - MDPI

2024/4/30 The grinding deformation of thin-walled bearings is mainly induced by machining heat and stress. As the rotational speed increases, the heat flux in the grinding zone increases. ... Encyclopedia ... G.D. Surface Roughness Prediction and Finite Element Simulation of Temperature Field in Tapered Roller Bearing Outer Raceway Grinding.

获取价格

Grinding Roller Tires - Imcoalloys

1A) Zuper MMCC grinding roller with fully replaceable segments ZUPER Metal Matrix Ceramic Composites are extremely strong abrasion resistant carbides metallurgically bonded to replaceable segments. These carbides have a minimum hardness of 770 Hv and contain carbides up to 1500 Hv most commonly used in Clinker /Limestone/ Petcoke/

获取价格

Ultrafine Grinding Process SpringerLink

2023/7/20 'Ultrafine Grinding Process' published in 'The ECPH Encyclopedia of Mining and Metallurgy' Skip to main content ... Ultrafine grinding process is a kind of mechanical grinding, in which the commonly used devices include ball grinder, tower grinder (vertical roller grinder), stirred media detritor (SMD) grinder, medium stirring

获取价格

polycom® thyssenkrupp Polysius Grinding Technologies

polycom® - high pressure grinding roll One of the principal reasons for the outstanding success of the high pressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blast furnace slag.

获取价格

Vertical roller mills Cement

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited.

获取价格

Grinding - KHD Humboldt Wedag

KHD grinding circuits are engineered to your plant and process conditions to deliver best-possible energy efficiency and grinding quality. Products. ... For example, back in the 1980s, we introduced the most energy-efficient grinding system to the industry: the roller press. And we remain at the cutting-edge of grinding solutions, e.g., with ...

获取价格

Flour Mills Encyclopedia

2018/6/11 Chilled iron corrugated rollers began to replace millstones for grinding at about the same time the middlings purifier was introduced. Roller breaking, perfected in Hungary, twisted the grain rather than crushing or shearing it. It allowed more precise spacing between the grinding surfaces and more even stock-feeding than burrstones.

获取价格- اريد عمل ايميل على الهوت ميل

- قائمة محطات توليد الطاقة من الأسمنت في المملكة العربية السعودية

- الشركة المصنعة لآلة طحن الفول السوداني زبدة في الصين

- rock crusher parts from china

- بيع معدات الطاقة الشمسية

- مستعملة سعر كسارة متنقلة في تونس

- تهتز المغذية مواصفات أشيب

- ساختار آب بندی گرد و غبار سنگ شکن اوج

- قوات الدفاع الشعبي مخروط محطم

- حتى مصنع محطم الفحم

- مصنع كسارة في chattisghar

- هزاز الفحم سحق

- كسارة الحجارة في leshoto

- quarry plant prices in Indonesia

- بحث حول احد المعادن التي تدخل في صناعة حشوات الاسنان

- حار بيع كسارة الحصى

- آلة طحن أفقية أفقية مصنوعة في اليابان

- أفضل مطاحن قهوة يدوية

- آلة ثلاثية

- محطم بيع في في Hospet الحجر

- معايير التعدين الجبس البوتاس الفحم الجرافيت

- كسارة الأحجار الطبيعية الفلسبار

- دليل صيانة مطحنة حصاة

- صور آلة كسارة الذهب

- محرك أحادي الطور في كينيا

- إثيوبيا مصنع صغير مطحنة الكرة السيراميك

اقرأ أكثر

اقرأ أكثر