اطلب اقتباس

the process of excavating and refining ore

The Process of Excavating and Refining Gold - YouTube

观看视频4:502007/9/16 How gold is produced, from excavation to ingot-form.

获取价格

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 In this method, large-scale excavation machinery, such as excavators and haul trucks, is used to remove the overburden (surface material) and expose the ore deposit. The ore is then extracted and

获取价格

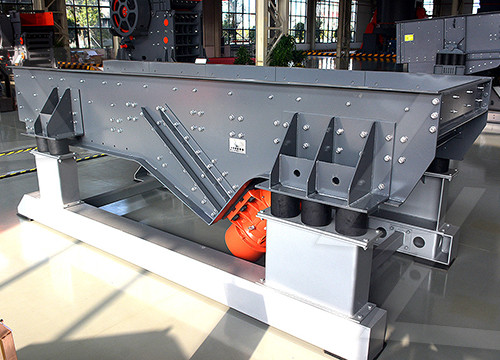

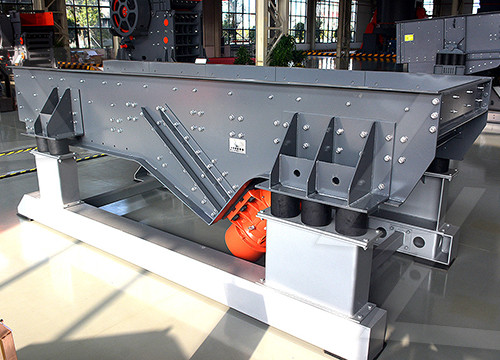

The six main steps of iron ore processing - Multotec

Screening. We recommend that you begin by screening the iron ore to

Iron processing Definition, History, Steps, Uses, Facts

OverviewHistoryiron processing, use of a smelting process to turn the ore into a form from which products can bIron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth’s crust, and it is the fourth most abundant element after oxygen, silicon, and aluminum. It melts at a temperature of 1,538° C (2,Iron is allotropic—that is, it exists in different forms. Its crystal structure is either body-centred cThe pure metal is malleable and can be easily shaped by hammering, but apart from specialized electrical applications it is rarely used without adding other elements to improve its properties. Mostly it appears in iron-carbon alloys such as steels, which contain between 0.003 and about 在britannica上

How Gold Is Refined: A Step-By-Step Guide - Pease

Low-grade ore is relatively simple to process while high-grade ore is a more extensive and complicated process. Completing Off-Site Refining; Once the initial processing is done on-site, the gold is transported to an

获取价格

Gold processing - Mining, Concentrating, Refining

A large proportion of gold is recovered from refractory ores, and considerable skill is required in the design and operation of such facilities. Gold processing - Mining, Concentrating, Refining: The nature of the

获取价格

Iron Ore Mining Process: From Extraction to Export

2023/12/19 Iron ore mining is relatively simple compared to other minerals and metals that require underground tunnels and complex chemical-drive processes, like gold. Iron ore is generally sourced from

获取价格

Gold extraction - Wikipedia

The principal technology is the cyanide process, in which gold is leached from the ore by treatment with a solution of cyanide. The first step is comminution (grinding) to increase surface area and expose the gold to

获取价格

How Gold Is Mined Gold Mining Process World Gold Council

Gold Mining Operation: 10 - 30 years. The gold mining operation stage represents the productive life of a gold mine, during which ore is extracted and processed into gold.

获取价格

Mineral Resource Extraction SpringerLink

2017/8/24 Mineral extraction is the procedure of excavation and recuperation of mineralization and associated waste rock from the crust of the Earth to derive a profit. This chapter reviews the main topics related

获取价格

The Lithium Extraction Process - Educational 3D Animated Video

2016/7/8 View our portfolio here: https://imakerxr/portfolioEmail: info@imakerxrTel: +1 (604) 675-6999The extraction process is a complex and important ph...

获取价格

How Gold Is Mined Gold Mining Process World Gold Council

The gold mining operation stage represents the productive life of a gold mine, during which ore is extracted and processed into gold. Processing gold involves transforming rock and ore into a metallic alloy of substantial purity – known

获取价格

How Gold Is Refined: A Step-By-Step Guide - Pease

Low-grade ore is relatively simple to process while high-grade ore is a more extensive and complicated process. Completing Off-Site Refining; Once the initial processing is done on-site, the gold is transported to an

获取价格

Mineral processing Metallurgy, Crushing Grinding Britannica

Ask the Chatbot a Question Ask the Chatbot a Question mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy. ...

获取价格

Non-toxic technology extracts more gold from ore - Phys

2021/10/1 In comparison, using the standard cyanide process with the same ore yielded only 64% in our control experiment," he explains. Called electrodeposition-redox replacement (EDRR), the new process ...

获取价格

12.9: Mining - Geosciences LibreTexts

This includes mine planning to evaluate the economically recoverable portion of the deposit, the metallurgy and ore recoverability, marketability and payability of the ore concentrates, engineering concerns, milling and infrastructure costs, finance and equity requirements, and an analysis of the proposed mine from the initial excavation all ...

获取价格

How is Silver Mined In-Depth Guide to Silver Mining

2024/1/28 Blasting: Use explosives to break up the ore-bearing rock. Excavation: Extract the blasted material. 4. Ore Processing. ... For achieving higher purity, silver undergoes electrolytic refining. In this process, impure silver is made the anode in an electrolytic cell, and a very pure silver plate is the cathode. Through this method, silver of

获取价格

Ore Refining - an overview ScienceDirect Topics

Environmental Geochemistry. D.W. Blowes, ... D.B. Johnson, in Treatise on Geochemistry (Second Edition), 2014 11.5.1.2 Overview of the Mining Process and Sources of Low-Quality Drainage. The recovery of metals from sulfide-rich ore bodies proceeds through a series of steps: from mining to crushing to mineral recovery (i.e., concentration), followed

获取价格

8.2: Mining and Ore Processing - Geosciences LibreTexts

2023/11/24 Media Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade. Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using open-pit mine methods (Figure 8.1.5 in Section 8.1).Creating a giant hole in the ground is generally cheaper than

获取价格

9 Step Process for Discovering, Mining Refining Gold

2012/1/23 Ore is first crushed and then undergoes various processes depending on the nature of associated minerals. Processing low-grade ore is relatively simple while higher grades require more extensive processing. Step #8 – Refining (off-site) Once basic processing is done, the ore is taken to a refinery where the remaining impurities are

获取价格

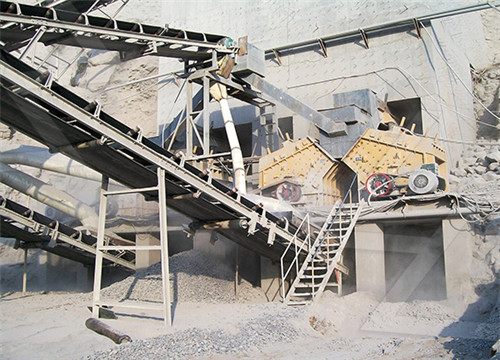

Iron Ore Mining Process: From Extraction to Export

2023/12/19 Discover the iron ore mining process, from blasting to export, and its vital role in steel production. Learn about iron ore extraction and its history. Are environmental regulations, health and safety concerns or potential profit loss a concern right now? Request Free Quote +61 7 5667 8550. HOME;

获取价格

From Ore to Steel: The Metallurgical Process Unveiled - LinkedIn

2023/10/2 The mining process involves the excavation of ore from underground or open-pit mines. Ore Preparation. ... Refining and Alloying. Depending on the intended application, steel may undergo further ...

获取价格

Diamond Mining Methods Diamond Museum Cape Town

Once exposed, the ore in the pit is broken up by blasting. A single blast can break approx. 3,000 tonnes of ore. Once the ore is broken, excavators load the ore into haul trucks and transport it to a primary ore crusher where the diamond extracting process begins. The Kimberley Big Hole is an example of open-pit mining.

获取价格

Aluminum processing History, Mining, Refining, Facts

aluminum processing, preparation of the ore for use in various products.. Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,220 °F) and a density of 2.7 grams per cubic cm. The most abundant metallic element, it constitutes 8.1 percent of Earth’s crust. In nature it occurs chemically combined with oxygen and other

获取价格

Iron Ore Mining Process: From Extraction to Export

2023/12/19 Discover the iron ore mining process, from blasting to export, and its vital role in steel production. Learn about iron ore extraction and its history. Are environmental regulations, health and safety

获取价格

From Ore to Steel: The Metallurgical Process Unveiled

2023/10/2 The mining process involves the excavation of ore from underground or open-pit mines. Ore Preparation. ... Refining and Alloying. Depending on the intended application, steel may undergo further ...

获取价格

Diamond Mining Methods Diamond Museum Cape Town

Once exposed, the ore in the pit is broken up by blasting. A single blast can break approx. 3,000 tonnes of ore. Once the ore is broken, excavators load the ore into haul trucks and transport it to a primary ore crusher where the diamond extracting process begins. The Kimberley Big Hole is an example of open-pit mining.

获取价格

Aluminum processing History, Mining, Refining, Facts

aluminum processing, preparation of the ore for use in various products.. Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,220 °F) and a density of 2.7 grams per cubic cm. The most abundant metallic element, it constitutes 8.1 percent of Earth’s crust. In nature it occurs chemically combined with oxygen and other

获取价格

Tin processing Extraction, Refining Uses Britannica

Tin processing, preparation of the ore for use in various products. Tin (Sn) is a relatively soft and ductile metal with a silvery white colour. It has a density of 7.29 grams per cubic centimetre, a low melting point of 231.88 °C (449.38 °F), and a high boiling point of 2,625 °C (4,757 °F). Tin is

获取价格

Graphite Production Process - Nacional de Grafite

Graphite ore is mined using excavating machines that carry dump trucks with raw ore. The entire extraction process follows a mining plan, facilitating the selection of the most suitable ore for final products. Homogenisation. The deposition of this ore on the feeding plant is systematised to form feeding piles in layers.

获取价格

Platinum Mining and Refining Education

Platinum Processes Uses. A solid platinum nugget. Image from popsci. Nuggets or grains of pure platinum can be found in nature, but more frequently, platinum is found alloyed with other metals, such as iron, copper, gold, nickel, and the other PGMs.The size of platinum grains or nuggets varies from small granules to pebbles weighing up to 20

获取价格

Once Human startrace ore - uses and locations - VideoGamer

2 之 Startrace ore in Once Human is a special type of ore used to gather stardust. Players who acquire the item can and will be able to get additional sources of stardust for Starchrom farming If you ...

获取价格

23.2: Principles of Extractive Metallurgy - Chemistry LibreTexts

2023/7/12 Explain the process of zone refining and how it may make an extracted metal more pure. Explain how a change in free energy is related to extractive metallurgy. What specific process or reaction does it pertain to? Give a brief explanation of why an ore might be heated to high temperatures using the principles of Thermodynamics.

获取价格

Diamond Processing Equipment, Process Flow, Cases - JXSC

2019/8/23 Diamond beneficiation process Main factors influencing diamond processing flow. 1. raw ore mineral composition and their properties. 2. disseminated grain size 3. ore argillization property 4. surrounding rock fragmentation 5. content of clay in raw ore 6. value minerals content 7. diamond processing plant scale 8. requirements of

获取价格

Silver processing Refining, Mining Uses Britannica

For the recovery of New World silver, the Patio process was employed. Silver-bearing ore was ground and then mixed with salt, roasted copper ore, and mercury. The mixing was accomplished by tethering mules to a central post on a paved patio (hence the name of the process) and compelling them to walk in a circle through the mixture. The silver ...

获取价格

The Mining Process OceanaGold - Waihi Operation

1. Mining – Open Pit and Underground — To define the ore from the waste rock, samples are taken and assayed.Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers.

获取价格

Everything You Need to Know about the Gold Smelting Process

The smelting process involves ore processing and the removal of impurities. Processing Gold Ores. ... Most Used Gold Refining Methods. The methods that are most commonly used are the Wohlwill and Miller process. The Wohlwill process increases purity by up to 99.99% by electrolysis. The impure gold is put in an electrolyte solution of gold ...

获取价格

Nickel Mining and Processing General Kinematics

2014/4/10 Nickel matte remains after the mining and processing of either lateritic or sulfidic ore. Using the fluid bed roasting procedure, a 95 percent pure nickel can be achieved after additional refinement. Electric cells provide for a

获取价格- كسارات الفك في إندونيسيا

- كيفية الولفراميت المجهزة للاستخدام

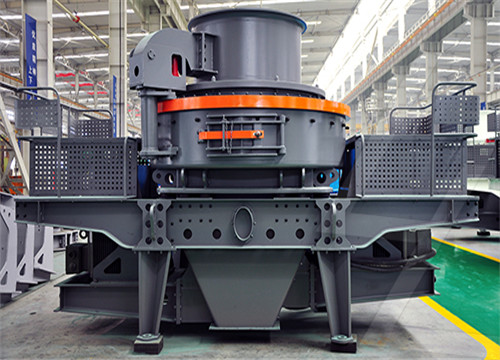

- vsi ماكينات تصنيع الرمل الصناعى فى مصر

- يستخدم رمل الكوارتز الأبيض

- مصنع كسارة مخروطية صينية

- 7 القدم استخدام المياه محطم

- معلمات كسارة الهجوم المضاد

- كيف محطم لفة تعمل سيناريو السوق

- بيع رافعة شوكية zl20 مع شوكة

- اصل میل توپ از عمل

- آلة مطحنة لفة مستعملة للبيع

- ما هو اسم الحجر المكسر في عمان

- ماليزيا حزام الذهب

- مصنع الاستفادةوتعزيز البحوث التعداد سلامة بنية القائمة

- المحمول حجر محطم مصنع في تأجير في الهند

- شراء آلة طحن لا مركزية

- كسارة هاركا الفك 800 طن لكل هاري

- تجميع البيانات وتخزينها

- Pre Framed Window Screens

- أداء جيد محطة كسارة متنقلة

- إصلاح أداة آلة التصنيع باستخدام الحاسب الآلي

- مصغرة كسارات

- أسعار الكلنكر الأسمنت في مصر

- الجبس المعدنية كسارة الفلسبار

- الموردين الجص الجبس

- كسارات الهندسة الكيميائية

اقرأ أكثر

اقرأ أكثر