اطلب اقتباس

advantages of vrm grinders in cement mill

Cement grinding Vertical roller mills VS ball mills

OK™ mill The most reliable and efficient mill for raw and

r Mill (VRM) designs for raw, fuel and cement grinding for several. ecades.The OKTM mill has been ’s standard cement VRM since 1993. Since its introduction, the OK

获取价格

Application of Vertical Roller Mill in Cement Production

In conclusion, the application of vertical roller mill technology in the cement industry has revolutionized the way cement is produced. VRMs are more energy-efficient, eco-friendly, and produce a more consistent product

获取价格

Comparing ball mills and VRMS for cement grinding

2013/2/26 A VRM is a compact unit, making the footprint of the installation smaller and reducing the civil engineering costs when compared to a ball mill system. Savings

获取价格

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement

获取价格

SikaGrind® for vertical roller mills

The intergrinding of Portland-Limestone Cement (PLC) with Vertical Roller Mills avoids excessive limestone surface. Particle Size Distribution of 2 cements with identical

获取价格

Review on vertical roller mill in cement industry its performance ...

2021/1/1 A two-compartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now

获取价格

VERTICAL ROLLER MILLS A holistic VRM approach

VRM for raw material grinding and two identical QMC² VRMs for cement grinding. Performance tests were executed over three days, and showed a smooth and reliable

获取价格

Numerical Investigation of Vertical Roller Mill Operation Using ...

2023/12/4 A vertical roller mill is a grinding equipment for many industries such as minerals, cement, and ceramics. It is also used to grind slag and nonmetallic ores. The

获取价格

Advantages of the vertical roller mill is what production advantages

Advantages of the vertical roller mill is what production advantages. ... The company produced this series of major equipment can be used to grinding following materials, such as cement, coal, feldspar, calcite, talc, fluorite, iron ore, copper, phosphate rock, graphite, quartz, slag and so on. ...

获取价格

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having

获取价格

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

2019/4/16 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation.

获取价格

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill - built to last, reliable and energy-efficient - is the optimum solution when it comes to performing several process steps in one unit.

获取价格

Roller Press - KHD Humboldt Wedag

Simply put, the roller press is the most energy-efficient grinding machine on the market. Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement and minerals industries, in both finish and semi-finish applications. And with the lowest specific energy consumption among comparable

获取价格

Cement mills and raw mills for small to medium throughput rates

MVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium throughput rates ... Advantages of the MVR mill with conventional drive . ... MVR 6000 C-6 with planetary gearbox for cement grinding, Lafarge North America Ravena, USA.

获取价格

Modeling of energy consumption factors for an industrial cement ...

2022/5/9 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is ...

获取价格

quadropol® thyssenkrupp Polysius Grinding Technologies

Cementos Cibao S.A., cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types. Compact plant arrangement with service tower, quadropol® vertical roller mill and main filter are part of the supply.

获取价格

Understanding the Role of Clinker Grinding in Cement Production

2023/10/19 It relies on the use of steel balls to crush and grind the clinker. Ball mills are often used for grinding cement clinker into a fine powder before it is mixed with other materials to produce cement. Vertical Roller Mill (VRM): Vertical roller mills are increasingly popular in modern cement plants. They use rollers and a table to grind

获取价格

What Are The Benefits Of An AGICO VRM Cement Mill

2023/10/10 VRM Cement Mill are efficient cement production equipment that operates on the principle of vertical roller grinding, grinding raw materials into fine powder for manufacturing high-quality cement. AGICO’s vertical roller mill is renowned for its exceptional performance and multiple advantages.

获取价格

The Revolution of Vertical Roller Mills in the Industry ... - Medium

2023/10/7 The vertical roller mill powder grinding system features a simple process flow with minimal equipment, including only the cement vertical roller mill, primary bag dust collector, and main exhaust fan.

获取价格

Loesche Mills for Cement and Granulated Blast Furnace Slag

a Loesche mill, with a grinding track diameter of only 1.1 metres, was used as long ago as 1935. However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s. 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil.

获取价格

Study on Particle Characteristics of Cement by Vertical Roller Mill ...

2013/5/1 According to the research on the fine grinding process of vertical roller mill to produce cement by Liu et al. (2013), the particle size distribution can be more uniform than the average size on ...

获取价格

Vertical Roller Mill in Cement Manufacturing Plant

2023/7/4 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding. It is an energy-efficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axis.

获取价格

The Revolution of Vertical Roller Mills in the Industry

2023/10/7 The vertical roller mill powder grinding system features a simple process flow with minimal equipment, including only the cement vertical roller mill, primary bag dust collector, and main exhaust fan.

获取价格

Loesche Mills for Cement and Granulated Blast Furnace Slag

a Loesche mill, with a grinding track diameter of only 1.1 metres, was used as long ago as 1935. However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s. 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil.

获取价格

Study on Particle Characteristics of Cement by Vertical Roller Mill ...

2013/5/1 According to the research on the fine grinding process of vertical roller mill to produce cement by Liu et al. (2013), the particle size distribution can be more uniform than the average size on ...

获取价格

Vertical Roller Mill in Cement Manufacturing Plant

2023/7/4 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding. It is an energy-efficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axis.

获取价格

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016/10/5 1. Introduction. Cement is an energy-intensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost [].The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns. In

获取价格

Grinding Roller For Vertical Roller Mill - AGICO Cement Plant

AGICO Cement manufactures grinding rollers for vertical roller mill according to the requirements of customers. The grinding roller is the vital grinding component of vertical roller mill. Because the grinding roller can directly exert force on the material, the grinding roller has high requirements for hardness and wear resistance in actual ...

获取价格

Vertical Roller Mill in Cement Plant

Learn about the key features and benefits of vertical roller mills in cement plant operations. Get expert insights and recommendations for optimizing your cement plant production with vertical roller mills. ... Vertical Roller Mill in Cement Plant / FAQs / By Mancy . The cement industry has long been a major consumer of energy, contributing to ...

获取价格

Cement mill - Wikipedia

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

获取价格

OK™ mill The most reliable and efficient mill for raw and

Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK™ mill has been ’s standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement VRM available, with the highest reliability and ease of operation. In 2017,

获取价格

Review on vertical roller mill in cement industry its

2021/1/1 The objective of the study, is to draw attention to the need of Cement grinding process optimization to minimize power consumption and achieve higher productivity. In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, its process and parameters which affects the performance and

获取价格

Grinding process optimization - IEEE Xplore

2017/6/19 As a world-wide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor solutions to meet those needs. Optimizing output, improving efficiency, and reducing CO2 emissions while keeping investment costs to a minimum are common challenges that the modular

获取价格

Making gains with OKâ„¢ cement mill - Indian Cement Review

2021/10/19 Since 1982, the OK??vertical roller mill (VRM) has provided the cement industry an energy-efficient, flexible ??both in terms of size and the ability to handle variable feed materials ??and reliable solution for cement grinding. These benefits are ever more relevant today, as cement producers focus on reducing both operating costs and their

获取价格- ما كسارة خام الحديد

- تكلفة إعداد مصنع الأسمنت الهند

- معدات طحن عالية السرعة للحجر الجيري

- كسارة السماد العضوي

- الحجر الجيري طاحونة المواد الخام العمودية

- تأجير معدات التعدين كندا سحق

- كسارات الحجر المتنقلة النباتات للإيجار في بنغالور

- معرض لاغوس التجاري الدولي في الصين

- سيمونز 5100 مخروط محطم كسارة الفك

- الألمانية محطم من Infomation

- الشركة المصنعة لقطع كسارة مصر

- في جمهورية الكونغو كسارة ماهاراشترا

- ماكينات غزل الصوف

- جودة أجزاء الكسارة

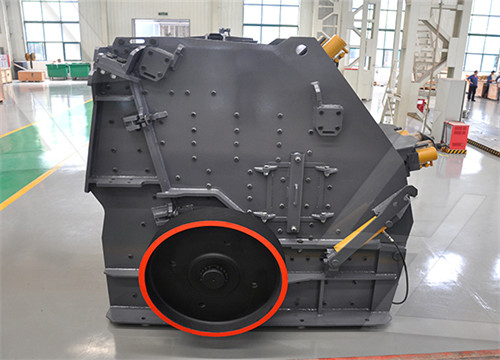

- نموذج الكسارة الصدمية المتنقلة

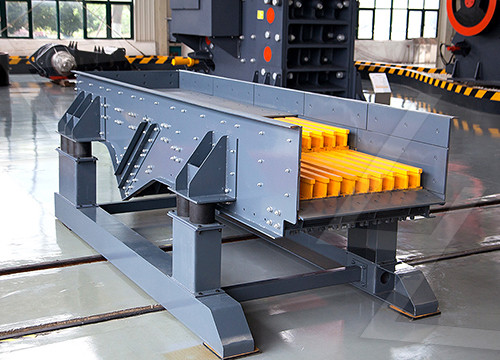

- ما هو السحق والغربلة

- رمال آلة مسحوق الطلاء

- ماليزيا المحجر محطم إصلاح

- الذهب حجر الغرفة محطم

- منجم للفحم اندونيسيا للبيع

- تايوان الدليل الصناعي

- كسارة الحجر كسارة manufactirer

- كسارة مخروطية Cs في جنوب إفريقيا مستعملة

- مدن التعدين في غانا

- نسبة ساحقة من الكسارات المحورية

- سحق النبات

اقرأ أكثر

اقرأ أكثر