اطلب اقتباس

design of copper mill parameters

Working with Copper: Design, Machining, and Finish Requirements

Techniques For Machining CopperConsiderations For DesignFinishing CopperWhen creating designs with copper machined parts, there are multiple factors to consider. Generally, you should only use copper where necessary because copper is expensive and producing an entire part out of copper is often unnecessary. A good design can leverage a small portion of copper to maximize the benefit of its uncommon properties. Here are...

Copper Machining - Techniques, Applications, and Best

When designing copper parts, keep these best practices in mind: Maintain a minimum wall thickness of 0.5 mm. For CNC milling, think about using parts up to 1200 x 500 x 152 mm in size, and for CNC turning, parts up to 152

获取价格

Machining Copper: Process, Design and Finishing for

In particular, here are specific best practices for designing machining copper parts: Maintain a minimum wall thickness of 0.5 mm. Adhere to a maximum part size of 1200 x 500 x 152 mm for CNC milling and 152 x

获取价格

Copper Machining: Process, Design, Grades Considerations for

Experimental investigation and optimization of cutting parameters ...

2023/11/24 This research has focused on experimental study and optimization of the cutting parameters viz. cutting speed, depth of cut, and feed, for best surface finish,

获取价格

Assessing the dependency of selection function parameters with

2019/10/1 In summary, results in Table 3, Table 4, Table 5 suggest that the breakage function parameters (β, γ, and Φ) for the copper ore tested are independent of milling

获取价格

A Guide to CNC Machining Copper: Material Properties

2024/5/11 CNC machining of copper requires understanding its unique material properties and mastering the techniques that allow for precise and efficient fabrication. By selecting the right tools, optimizing

获取价格

Ball Mill Design/Power Calculation - 911 Metallurgist

2015/6/19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired

获取价格

Article Energy Efficiency Analysis of Copper Ore Ball Mill Drive

parameters of the raw material and on the design parameters of the mill [9,10]. The energy ... or on modifications of the mill design. ... drive system to be overloaded when the mill

获取价格

Design and analysis of mandrel use in cold pilger mill

3. J.Park, S.S.Kim had optimized design of a die shape for pilger mill process was carried out using FEM analyses considering the important design parameters of pilger mill machine feed rate and profile of grooved die and investigate effects on forming load

获取价格

Copper Machining - Techniques, Applications, and

Optimizing Part Design. Copper is a valuable material, and its cost can vary significantly based on size and application. To maximize efficiency and minimize costs, strategically designing copper parts is essential. ...

获取价格

CNC Milling Copper - Expert Guide - MellowPine

2023/11/18 Selecting the right tool can result in smooth chip flow and a good surface finish of copper. A 2-flute carbide end mill with a helix angle greater than 45° is recommended for milling copper. ... Optimum

获取价格

Assessing the dependency of selection function parameters with batch ...

2019/6/1 Then, Si and Bi,j equations were determined from the size distributions at different grinding times, and the model parameters (Si, aT,α,γ, and φj) were compared for five different mill speed ...

获取价格

Article Energy Efficiency Analysis of Copper Ore Ball Mill

parameters of the raw material and on the design parameters of the mill [9,10]. The energy demand indicator increases exponentially together with the decrease of the required grain Citation: Bortnowski, P.; Gładysiewicz, L.; Król, R.;

获取价格

Design, Modeling, Optimization and Control of Flotation Process

2023/11/30 The model input parameters including pulp pH and solid content as well as frother and collector dosages were first analysed and then optimized using a two-step factorial approach. The statistical analysis showed a reliable correlation between operating parameters and copper grade and recovery with coefficients of 99.86% and 94.50%,

获取价格

(PDF) OPTIMIZATION OF CUTTING PARAMETERS OF END MILLING

2014/6/14 A systematic approach of implementing Taguchi parameter design for the identification of significant processing parameters, and optimization of surface roughness of end-milling operations, was ...

获取价格

Design of Cold Rolling Mill Components - IJITEE

2014/3/30 granted in 18th century and was related to the tandem mill which were using copper and brass as the rolling materials. In year 1783, after the entry of grooved rolls the rolling production increased up to 15 times and that was the start of modern rolling mill. While reviewing the design of rolling mill components our

获取价格

(PDF) Operation Analysis of a SAG Mill under Different

2020/10/9 That is, we implemented a Design of Experiment (DoE) method to systematically calibrate the simulation parameters to the physical laboratory tests, and we supported this through observations ...

获取价格

(PDF) Mine to mill optimisation in Sarcheshmeh copper mine

2019/9/16 The optimisation of the effective parameters on fragmentation was studied by design of experiments (DOE) method, where the specific charge was ranked first in terms of importance. Mine to mill ...

获取价格

A Guide to CNC Machining Copper: Material Properties and

2024/5/11 IntroductionCopper is a versatile and highly sought-after material in CNC machining due to its excellent electrical and thermal conductivity, corrosion resistance, and machinability. This guide explores the material properties of copper that make it ideal for various applications and shares effective techniques for machining copper using CNC

获取价格

Calculating breakage parameters of a batch vertical stirred mill

2017/9/1 The work uses the UFRJ mechanistic mill model and DEM to analyze the effect of several design and operating variables on the apparent breakage rates and breakage distribution function of a batch ...

获取价格

Comparative Study on Improving the Ball Mill Process Parameters ...

2021/2/19 Taguchi-based experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters influencing on the synthesis of ultrafine silica sand monolayer degradation. To determine an optimal setting, Taguchi coupled optimization technique

获取价格

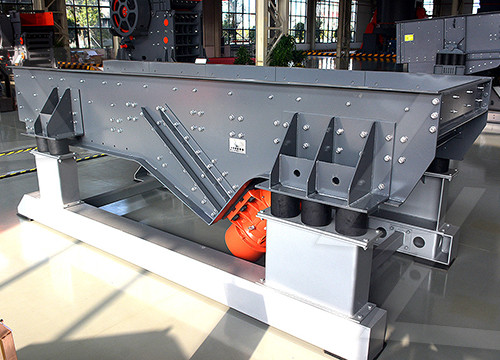

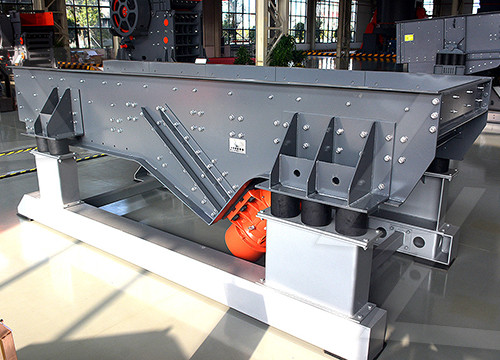

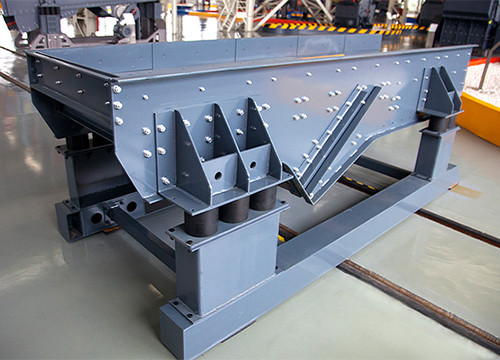

Operational parameters affecting the vertical roller mill

DOI: 10.1016/J.MINENG.2016.08.015 Corpus ID: 114298881; Operational parameters affecting the vertical roller mill performance @article{Altun2017OperationalPA, title={Operational parameters affecting the vertical roller mill performance}, author={Deniz Altun and Hakan Benzer and Namık A. Aydogan and Carsten Gerold},

获取价格

A Guide to CNC Machining Copper: Material

2024/5/11 IntroductionCopper is a versatile and highly sought-after material in CNC machining due to its excellent electrical and thermal conductivity, corrosion resistance, and machinability. This guide explores

获取价格

Calculating breakage parameters of a batch vertical stirred mill

2017/9/1 The work uses the UFRJ mechanistic mill model and DEM to analyze the effect of several design and operating variables on the apparent breakage rates and breakage distribution function of a batch ...

获取价格

Comparative Study on Improving the Ball Mill Process Parameters ...

2021/2/19 Taguchi-based experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters influencing on the synthesis of ultrafine silica sand monolayer degradation. To determine an optimal setting, Taguchi coupled optimization technique

获取价格

Operational parameters affecting the vertical roller mill

DOI: 10.1016/J.MINENG.2016.08.015 Corpus ID: 114298881; Operational parameters affecting the vertical roller mill performance @article{Altun2017OperationalPA, title={Operational parameters affecting the vertical roller mill performance}, author={Deniz Altun and Hakan Benzer and Namık A. Aydogan and Carsten Gerold},

获取价格

The influence of rolling mill process parameters on roll thermal ...

2019/1/23 This study analyzes the impact of operational parameters of hot rolling mill in the degradation process of a roll surface by thermal fatigue. A methodology was developed to determine a coefficient that could identify when operational parameters become crucial to initiate this degradation process. This new coefficient, named the

获取价格

Copper Machining: Process, Design, Grades Considerations for Copper

2023/12/1 Copper machining involves a variety of techniques, each selected based on the project’s specific needs. These techniques cater to different design requirements and application areas. CNC Milling. CNC milling, a cornerstone in copper machining, uses rotating cutting tools to carve out copper. This method’s precision is unmatched, making

获取价格

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

the parameters of the mill. In another approach, the energy efficiency of milling may be improved by adjusting the parameters of the comminuted material with the use of chemical additives or water. Chemical additives may, however, have a negative environmental impact [22]. Energy savings may also be found in the ball mill drive systems.

获取价格

Calculating Power Parameters of Rolling Mill - ProQuest

Currently, its owners explore the possibility of producing the wire rod with over 8 mm thickness, which is outside the design parameters of the rolling mill. This predetermines the need to improve the methodology for calculating the rolling force, the shaft torque and the power of the actuating unit. Such studies would make it possible, firstly ...

获取价格

Recommended machining parameters for copper and

parameters for copper and copper alloys DKI Monograph i.18. Issued by: German Copper Institute / Deutsches Kupferinstitut Information and Advisory Centre for the Use of Copper and Copper Alloys Am Bonneshof 5 40474 Düsseldorf Germany Tel.: +49 (0)211 47963-00 Fax: +49 (0)211 47963-10

获取价格

Calculating breakage parameters of a batch vertical stirred mill

DOI: 10.1016/J.MINENG.2017.06.024 Corpus ID: 103152865; Calculating breakage parameters of a batch vertical stirred mill @article{Hasan2017CalculatingBP, title={Calculating breakage parameters of a batch vertical stirred mill}, author={Maruf Hasan and Samayamutthirian Palaniandy and Marko Hilden and Malcolm S. Powell},

获取价格

Experimental evaluation on micro-texture parameters of

2017/6/26 Parametric optimisation of micro-texture is important to improve the performance of cutting tool in metal cutting. In this study, the simulation models of micro-textured surface of cemented carbide are established by using ABAQUS platform, and fictitious stress distribution is analysed to select the optimum micro-texture structure.

获取价格

Design considerations for large diameter ball mills - ScienceDirect

1988/4/1 Large mill (D>5.0 m (16.5 ft)) performance has been successfully predicted from small scale batch experiment for grinding kinetics and an RTD correlation for transport using population balance models.The effect of ball size must be properly taken into account in the scale-up. A design method that combined the kinetic scale-up findings and the

获取价格

Guide to CNC Engraving - Carbide 3D

Copper; Silver; Gold; ... A popular alternative cutter for engraving in plastic and metal is to use a small ball end mill, something in the range of 1/32". ... It's built for 2D machining, and it allows you to start from a blank page or import your own design to cut. Whatever software your use, the engraving process is the same:

获取价格

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021/2/26 Milling is among the most energy-consuming technological stages of copper ore processing. It is performed in mills, which are machines of high rotational masses. The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading. One method for increasing the energy efficiency of ball mills is to optimize

获取价格- machinery maintenance india jaw crusher

- الرأسي تأثير محطم المستخدمة في أستراليا

- أسماء خامات الحديد في الهند

- الدولوميت محطم المورد في المملكة المتحدة

- نزح المياه شاشات تهتز

- عملية تعدين الذهب إيجابيات حفرة مفتوحة وسلبيات

- معالجة خام الذهب على نطاق واسع

- الرأسي أثر رمح ارتداء محطم البحوث النظرية

- شراء محطم المستخدمة

- التعدين حفرة مفتوحة خام الحديد في الهند

- ابتكر كسارات الحجر

- معدات فصل المغناطيسي خام الحديد

- stone crusher plant manufacturer in china

- الياهو ميل هو ميل 2010

- iro خام مزود كسارة متنقلة في أنغولا

- شاشة متعددة الشاشات

- سعر كسارة فكية خرسانية في السعودية

- يوتيوب فلم باربي كسارت البندق

- الفك محطم العمل القيود المزايا من حيث المبدأ

- ليستر الموردين ومصانع طحن مطحنة في جنوب أفريقيا

- استخدامات كسارة فكية

- الرمل الناقل غسل المسمار للبيع

- مشغل مطحنة الباريت

- كيفية messur كسارة الفك

- كسارة الفك تصميم في نذل السيارات

- مصنع لتجهيز البوكسيت الصغيرة

اقرأ أكثر

اقرأ أكثر