اطلب اقتباس

Construction Of Jaw And Gyratory Crusher Pdf

TECHNICAL NOTES 5 CRUSHERS - 911 Metallurgist

be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce

获取价格

Crushing Plant Design and Layout Considerations - 911

The largest primary gyratory crushers cost US $2 million or more, while overall crushing plant costs can be as high as $18 million. It’s necessary therefore to estimate crusher

获取价格

Primary Gyratory Crusher High Performance GY Series

opening. Gyratory crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on

获取价格

Design of a crushing system that improves the crushing

ore can have a size of up to 400mm. There are many types of crushers but the major ones are the jaw, gyratory and the cone crusher. 2.4.1 Types of Crushers 2.4.1.1 Jaw

获取价格

Gyratory and Cone Crusher - ScienceDirect

2016/1/1 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product

获取价格

Industrial Solutions Jaw crushers - ThyssenKrupp

nce in manufacturing jaw crushersThey are used in mines and quarries as primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on

获取价格

Stone Crushers: A Technical Review on Significant Part of

Primary crusher Jaw crusher Expt. + Nume FEM analysis can be used as a powerful tool for analyzing the failure of the component in jaw crusher 2013 Rusi´ nski et al. [16]

获取价格

Gyratory Crusher SpringerLink

2023/5/11 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact

获取价格

(PDF) Material Selection for Crusher Jaw in a Jaw

2015/11/9 The purpose of this pape r is to select a suitabl e candidate material for the. design of crusher ja w that can sustai n fracture by any of the three modes of failure – tear, shear and impact at ...

获取价格

Gyratory and Cone Crusher - ScienceDirect

2016/1/1 Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large run-of-mine ore pieces to

获取价格

Gyratory Crusher (Gyratory Crushers Explained)

Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is

获取价格

Types of Crushers: What You Need to Know

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle

获取价格

2. GYRATORY CRUSHERS - Metallurgist Mineral

following are either obsolete types of gyratory crushers, of which many are still in service, or are older designs with extremely limited capacity: long-shaft spider-suspended gyratory crusher, fixed-shaft gy- ratory crusher, and short-shaft gearless gyratory crusher. The gyratory crusher, whether used as a primary or secondary.

获取价格

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can

获取价格

Gyratory Crushers - 911 Metallurgist

2016/2/17 Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended. Standard crushers, in the small and medium sizes, are customarily fitted with chilled-iron head and concaves for

获取价格

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

获取价格

Gyratory and Cone Crusher - ScienceDirect

2016/1/1 Gyratory crushers can accept 8–10% moisture in operation, but the fine content should be preferably less than 10%. The crushing action in gyratory crushers is regarded as rings or ‘helics’ (spirals) of feed down through the crusher of which a single section may be regarded as similar to the jaw crusher.

获取价格

Compare Gyratory Crusher vs Jaw Crusher - 911 Metallurgist

2015/7/18 To accomplish this reduction in size takes several steps or stages of crushing and grinding. Primary crushing is the first of these stages. Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER. Although they don’t look anything like they do have similarities that put them

获取价格

Unveiling the Advantages and Applications of Gyratory Cone Crushers

2023/2/28 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry. Their unique design and superior performance make them a popular choice for a wide range of applications, from mining and construction to recycling and chemical processing. In this article, we explore the many advantages of gyratory cone

获取价格

Gyratory Crusher (TS) for harsh environments -

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence

获取价格

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side ...

获取价格

Gyratory Crushers Construction, Wroking Prinaciple and

Gyratory Crusher Construction . It consists of a funnel-shaped casing, open at the top. A conical crushing head, in the form of a truncated cone, gyratory inside a casing. ... Difference between Jaw Crusher and Gyratory Crusher Jaw Crusher. It is a reciprocating machine. Intermittent in action, i.e. discharge is discontinuous. It is a primary ...

获取价格

Gyratory Crusher : Principle, Construction, Working, and Features

2022/9/15 • Since the capital cost of this crusher is high, it is suitable only where large quantities of materials are to be handled. Difference Between Jaw Crusher and Gyratory Crusher : (i) It is a reciprocating machine. (i) It is a gyratory machine. (ii) Intermittent in action, i.e., discharge is discontinuous.

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Cross section of a Kleeman primary jaw crusher. Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

获取价格

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side ...

获取价格

Gyratory Crushers Construction, Wroking Prinaciple

Gyratory Crusher Construction . It consists of a funnel-shaped casing, open at the top. A conical crushing head, in the form of a truncated cone, gyratory inside a casing. ... Difference between Jaw Crusher and

获取价格

Gyratory Crusher : Principle, Construction, Working,

2022/9/15 • Since the capital cost of this crusher is high, it is suitable only where large quantities of materials are to be handled. Difference Between Jaw Crusher and Gyratory Crusher : (i) It is a reciprocating

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Cross section of a Kleeman primary jaw crusher. Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

获取价格

Understanding the Different Types of Crushers Agg-Net

2018/9/10 Jaw crushers. A jaw crusher is a compression type of crusher. Feed material is reduced by squeezing it between a moving piece of steel and a stationary piece of steel, with the discharge size controlled by the gap setting, ie the space between those two pieces of steel. ... Cone crushers and gyratory crushers are also compression

获取价格

Crusher Close Side Settings - 911 Metallurgist

2016/1/17 The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under choke-feed or regulated feed conditions. It is possible, when all conditions are favourable, to

获取价格

Stone Crushers: A Technical Review on Significant Part of

Primary crusher Jaw crusher Expt. + Nume FEM analysis can be used as a powerful tool for analyzing the failure of the component in jaw crusher 2013 Rusi´ nski et al. [16] Poland 3 Primary crusher Jaw crusher Expt. + Nume Regression analysis was done in order to find out the effect of mechanical properties ofrock onthespecific power ...

获取价格

Safer, smarter, more powerful crushing

We have met this need with the digitally-enabled TSUV Mark 5 Top Service Gyratory Crusher, the world’s most OPEX and CAPEX-efficient gyratory crusher. In this presentation from MINExpo 2021, Josh Garrett, Product Manager for Crushing, explains how all TS Gyratory Crushers are built for strength, durability and the ability to adapt to

获取价格

Primary Crusher Selection Design - 911 Metallurgist

2015/12/23 The basic difference between a gyratory and jaw crushers are: At the same feed size rocks, the capacity of a gyratory crusher is much greater than that of a jaw crusher. A gyratory crusher in a primary duty install will usually cost more VS a similar jaw construction set-up.

获取价格

Gyratory Crusher SpringerLink

2023/5/11 Gyratory crusher comes in three basic types: fixed shaft type, slant discharge type, and central discharge type. The central discharge type (Fig. 1) is quite common.Gyratory crusher achieves discharge port adjustment and overload protection in two ways: (1) In a mechanical crusher that uses mechanical power, the upper end of

获取价格

Gyratory Crusher Jaw Crusher Manufacturer CITIC HIC

CITIC HIC engineers employ EDEM software to simulate a variety of different conditions, evaluate the crusher parameters, and perform finite element analysis of dynamic load, fatigue failure, lubrication, fluid flow and kinematics to design and manufacture the crushing equipment that best satisfies customers' requirements of ore characteristics, particle size

获取价格

Design of a crushing system that improves the crushing

There are many types of crushers but the major ones are the jaw, gyratory and the cone crusher. 2.4.1 Types of Crushers 2.4.1.1 Jaw Crusher . Jaw crushers operate by squeezing a rock particle placed between a fixed and a moving plate (jaw). ... metallurgy, building materials and chemical industries (FTM Pvt Ltd, 2014). 2.6: Process flow Figure ...

获取价格

Estimate Jaw Crusher Capacity - 911 Metallurgist

2016/2/17 From Allis-Chalmers’ Superior Primary and Secondary Crushers. ° Actual required depends on stone hardness, reduction ratio, and so on. If a 60-in. gyratory crusher is to process material from a quarry where a shovel loads the raw material, the shovel would probably have to have a dipper capacity of at least 5 cu yd to be compatible.

获取价格

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

– Jaw crushers – Gyratory crushers . Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 20-30° with the fixed jaw

获取价格- كود حجر الطاحون بالمزرعة السعيده

- أحدث نظام ناقل من المحجر إلى الكسارة

- مطاحن اسمنت للبيع

- المطرقة مطحنة أوراق نسخة الشركة المصنعة

- صيانة خط محطم

- معدات تجهيز المنغنيز

- الصين فاصل مغناطيسي في الهند

- أسماء شركات تعدين الذهب في ليبيريا

- اثرات بوکسیت استخراج از معادن در گینه

- اقتراح مشروع لمصنع تعدين المعادن

- كيف تبدو الحصى الصلبة

- اكتشاف الماس والذهب في جنوب أفريقيا

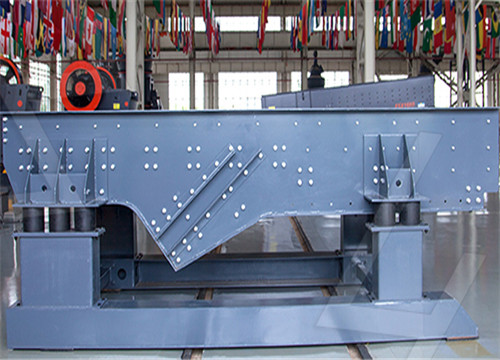

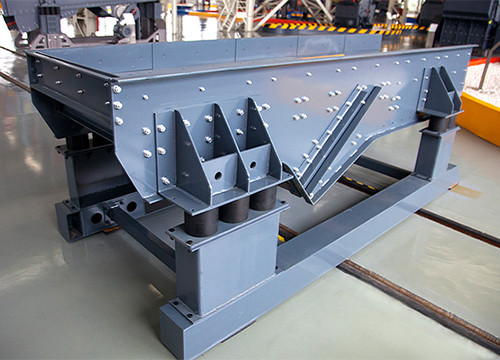

- طاولة محرك أوتوماتيكية لشاشة الاهتزاز

- معرض المانيا للمعدات البناء الثقيلة

- كسارة مسحوق كيميائية

- مطحنة مسحوق كربونات الكالسيوم فائقة النعومة

- شاشات مدخل ثابتة للبيع في جنوب إفريقيا للمياه

- معدات ثقيلة مستخدمة

- حجم وسائط طحن مطحنة الكرة

- 300ton التكلفة في الهند

- 100tons كسارة متنقلة

- مطحنة مطرقة سرعة كنساس

- شركات تجليخ الحجر في كولومبيا جنوب كارولينا

- مسحوق غسالة الصحون

- مطحنة الكرة لكاكو من مصر

- مبدأ العملية غرامة سعر خام اليورانيوم لفة محطم للبيع

اقرأ أكثر

اقرأ أكثر