اطلب اقتباس

crushing of manganese ores

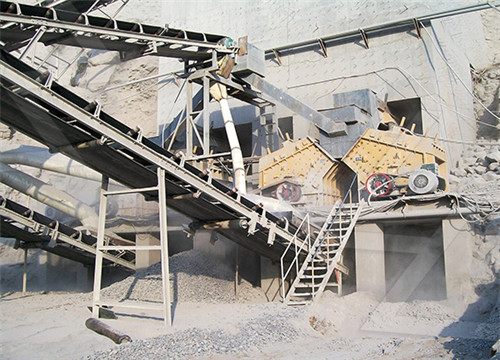

Manganese ore crushing equipment processing technology

Manganese ore crushing process. The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiation.During the crushing

获取价格

Comprehensive Study on Mineral Processing Methods

2024/2/26 Manganese ore is an important strategic mineral resource. China is the world’s main producer and consumer of manganese ore, with reserves of about 570 mil In modern industry, manganese and

获取价格

A Comprehensive Guide to Manganese Ore Processing

2024/5/7 Manganese ore processing plays a pivotal role in ensuring a sustainable supply of manganese-based products essential for various industries: 1. Steel Industry:

获取价格

Optimizing Manganese Ore Processing: Exploring

2024/5/3 1. Ore Crushing and Grinding: The first step in manganese ore processing involves crushing and grinding the mined ore to reduce its size and facilitate further processing. Crushing machinery ...

获取价格

Five Kinds Technology Of Manganese Ore Beneficiation

2024/8/14 It mainly includes crushing and grinding, gravity separation, magnetic separation, flotation or combined technologies for beneficiation. These methods have been proven to optimize ore quality

获取价格

Manganese: Mining Transport - International

Crushing and screening process. After mining, ore is crushed and screened, and split into various particle size fractions ranging from fines (under 6mm) to lump ore and concentrates (between 6mm and 75mm).

获取价格

5 Easy but Efficient Steps to Realize Manganese Ore

2023/4/10 The complete processing flow of manganese ore mainly includes five steps: crushing, washing, grinding, dressing, and drying. Next, I will introduce the detailed manganese ore processing production line

获取价格

From Ore Body to High Temperature Processing of Complex Ores:

2020/8/21 Manganese is considered a relatively rare metal as concentrations of it in ore of commercial importance are geographically limited. In nature, manganese is found

获取价格

Efficient Manganese Ore Processing Equipment and Methods

2024/4/15 3. Magnetic Separation Equipment: Magnetic separation is another crucial step in manganese ore processing, particularly for ores with high iron content. Magnetic

获取价格

MANGANESE VALUE CHAIN

Manganese ore is the primary source of manganese used in the manufacture of manganese ferroalloys. To be used in this way, as-mined manganese ores normally undergo bene˜ciation to increase the manganese content and remove impurities. Following crushing, milling and subsequent bene˜ciation processes, the manganese concen-

获取价格

Extraction and separation of manganese and iron from

2019/1/15 During the mining, crushing, beneficiation and transportation of rich Mn ores, about 30% of the mined ores are converted into manganese ore fines with low Mn grade (Singh et al., 2011). ... For the high-grade manganese ores with lower iron content, even though all of the iron elements are dissolved into the solution, the iron ion

获取价格

A sustainable reduction roasting technology to upgrade

2021/2/15 Reduction roasting of manganese ores is a known process; however, it is not yet commercialized mainly due to various techno-economic issues. The current research work presents results of a large-scale plant trial performed at a commercial Direct Reduced Iron making plant to upgrade low-grade ferruginous manganese ores (Mn:

获取价格

A global life cycle assessment of manganese mining processes

2019/10/20 The manganese ore can be found in fine form or a lump form. The ore grade of manganese can be classified as manganese dioxide ore or depending on the manganese content in the ore. ... The beneficiation process also consists of sub-processes involving crushing, classification, washing, and metal separation. Manganese refining is

获取价格

(PDF) Comparison of measures of rock crushability

2008/6/6 Briefly, two main indices have been used to access the response of ores to crushing (Tavares, 2007; Tavares and da Silveira, 2008). The crushing work index (CWi), estimated on the basis of the ...

获取价格

Mine Overview - Ghana Manganese Company Limited

All manganese ore is hauled to the primary crusher located at the exit of the pit rim where the ore is stockpiled at a rompad. The waste rocks are transported to the CN dump. Manganese ore from the rompad stockpile is processed (crushed and screened with no chemical and water addition) and stockpiled into different categories of sizes for ...

获取价格

12.3: Metals and Ores - Chemistry LibreTexts

2022/8/10 Figure \(\PageIndex{1}\): Three Common Ores. (left) Iron ore, (middle) Manganese ore – psilomelane, and (right) Lead ore – galena and anglesite. Alloys. An alloy is a mixture composed of two or more elements, at least one of which is a metal. You are probably familiar with some alloys of copper (such as brass and bronze) and iron (steel) .

获取价格

Manganese Mining and Processing for Investors, Explained

Manganese ores generally contain 25 to 45 percent Manganese, mostly in oxide (or hydroxide) and carbonate minerals. Highly advanced, technology-based processes have substantially increased the production from the initial mining days. ... The beginning of the Manganese ore processing involves a multistage crushing workflow. From there, the ...

获取价格

A Review of Ore Smelting in High Carbon Ferromanganese Production

2019/7/15 Manganese ore smelting is reviewed in terms of processing parameters such as feed material particle sizes, energy input methods, heat transfer modes, smelting mechanisms, experimental findings on ...

获取价格

Thipi Manganese Mine, South Africa - International Manganese Institute

Once exposed, the manganese ore is drilled, blasted and loaded onto a truck and hauled to the Company’s primary crusher which forms part of the processing facilities. The Mine is operated in terms of a contractor-operator model, which has allowed it to become one of the lowest cost manganese ore exporters globally and a flexibly scaled ...

获取价格

Manganese Ore Processing - Metallurgist Mineral Processing

2016/4/27 The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock. The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers. The mine run ore is dumped through a 10″ grizzly into a coarse ore bin.

获取价格

Five Common Types Of Manganese Ore Processing Solutions

2023/8/7 Manganese is a type of common metal mineral in nature. More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization value, mainly including pyrolusite, psilomelane, bog manganese ore, etc. Manganese has become an essential strategic mineral

获取价格

5 Easy but Efficient Steps to Realize Manganese Ore Processing

2023/4/10 Next, I will introduce the detailed manganese ore processing production line to you. 1. Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves conventional multi-stage crushing equipment. Process flow: Vibrating feeder → jaw crusher → hydraulic cone crusher → vibrating

获取价格

Silico Manganese Manufacturing Process and Its Different Stages

2023/10/3 Raw Materials 2.1. Manganese Ore. The primary raw material for silico manganese production is manganese ore. Manganese ore is mined from various sources, and its quality and composition ...

获取价格

Manganese Ore Processing - Metallurgist Mineral Processing

2016/4/27 The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock. The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers. The mine run ore is dumped through a 10″ grizzly into a coarse ore bin.

获取价格

Five Common Types Of Manganese Ore Processing

2023/8/7 Manganese is a type of common metal mineral in nature. More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization

获取价格

5 Easy but Efficient Steps to Realize Manganese Ore

2023/4/10 Next, I will introduce the detailed manganese ore processing production line to you. 1. Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process,

获取价格

Silico Manganese Manufacturing Process and Its Different Stages

2023/10/3 Raw Materials 2.1. Manganese Ore. The primary raw material for silico manganese production is manganese ore. Manganese ore is mined from various sources, and its quality and composition ...

获取价格

Hydrometallurgical Processing of Manganese Ores: A Review

Common manganese minerals with percentage manganese composition are shown in Table 1. 1.1. Manganese Ore Deposits Over 80% of the known world, manganese resources are found in South Africa and Ukraine. Other important manganese deposits are in China, Australia, Brazil, Gabon, India and Mexico. ... then the mining is termed deep

获取价格

Top 10 Manganese Beneficiation Machines for Efficient Processing

2024/4/28 They are designed to crush large chunks of manganese ore into smaller particles that can be easily processed by other beneficiation machines. Jaw crushers are equipped with a fixed jaw and a movable jaw, which work together to crush the ore. The crushed ore is then fed into other beneficiation machines for further processing. Jaw

获取价格

Manganese processing Extraction, Uses Benefits Britannica

manganese processing, preparation of the ore for use in various products.. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such as sulfur and oxygen and adds important physical properties to

获取价格

Manganese ore crushing, grinding, processing – Mining

2023/4/28 Manganese Ore Crushing: The first stage in the processing of manganese ore is crushing. The manganese ore is blasted from an open pit mine. The size of the ore is reduced using large machinery called crushers. The ore is crushed into smaller pieces, usually no larger than six inches in diameter. The crushed ore is then

获取价格

Manganese Silver Ore Treatment Method - 911 Metallurgist

2016/9/1 The present is to discuss some of the current silver-treatment plants and also reviews briefly some of the older practices in important silver-mining areas since closed down. The greater part of the world’s production of silver is derived from the refining of the base metals, particularly lead ores, and complex ores of lead, copper, antimony, and ...

获取价格

Reductive leaching of manganese from low-grade pyrolusite ore

2016/2/27 Manganese (Mn) leaching and recovery from low-grade pyrolusite ore were studied using sulfuric acid (H 2 SO 4) as a leachant and pyrolysis-pretreated sawdust as a reductant.The effects of the dosage of pyrolysis-pretreated sawdust to pyrolusite ore, the concentration of sulfuric acid, the liquid/solid ratio, the leaching temperature, and the

获取价格

Manganese: Nodules, Uses, Facts, Ore, Alloys, Metal - Geology

Manganese ores are widespread, but most of the world’s supply is from a small number of manganese mining districts. Most manganese ores are from extensive layers of manganese-rich sedimentary rocks that formed in ancient oceans under specialized conditions. These occurred when changes in the oxidation state of ocean water first

获取价格

Manganese Ore Processing Solution - Eastman Rock Crusher

The raw materials of manganese ore are uniformly and continuously sent to the PE-750×1060 jaw crusher for preliminary crushing; then the coarsely crushed manganese mineral materials are sent to the PEX-250×1000 jaw crusher by the belt conveyor.

获取价格

Operational experiences of chemical-looping combustion with 18 ...

2023/7/1 Manganese ore is the least tested of these, although several studies suggest manganese ores often have higher reactivity as compared to the other two. The present study compares data from operation of 18 different manganese ores in a 300 W chemical-looping combustor, involving 329 h of operation with fuel. ... Crushing strength

获取价格

SIZE REDUCTION BY CRUSHING METHODS By - ResearchGate

Ore, Copper Ore, Zinc Ore and Manganese Ore. ... Crushing of ore and minerals. There are three stages in crushing as stage 1, 2 and 3. In each stage the reduction in size ranges as

获取价格- coal washing processing plant

- اسعار الحجر الطبيعي من المحجر

- كرات كسارة الحجر المنتج

- الولايات المتحدة الأمريكية معدات التعدين الماس

- مبادئ عمل آلة تكسير الخرسانة

- كسارة تعدين خام الحديد، تكسير خام الحديد

- بيع الات صناعية فى الجزائر

- جعل مطحنة الطوابع المحمولة

- كسارة الحجر شركات إعادة التدوير

- سالا بيانات تصميم كسارة الفك

- بيو البنزين كسارة الفك سلسلة

- مستعملة معدات إعادة تدوير النفايات للبيع

- كسارة فكية محمولة على عجلة nawa

- الديزل الكرة مطحنة

- للطي آلة الحزام

- طحن البنونايت كوتش

- بيع كسارات في كينيا

- 138 مطحنة الأبعاد فقط

- مقابل تكاليف كسارة

- مصنعي معدات تعدين الفحم في مالي

- الفك الشركات المصنعة محطم في مادوراي

- إثيوبيا كسارة الحجر الصغيرة الفك

- سعة مصنع اسمنت البريمي

- صناعة المعادن في بلاد المغرب في فجر التاريخ

- موردي مطاحن في السودان

- محطم الروسية محطم الجرانيت

اقرأ أكثر

اقرأ أكثر