اطلب اقتباس

method of working of roll crusher in Mexico

Construction Working and Maintenance of Crushers for

methods. For example, a single-roll crusher, employ shear together with impact and compression. Shear crushing is normally used under following conditions. When material is somewhat friable and has relatively low silica content. For primary crushing with a

获取价格

New insights into double roll crushing - ScienceDirect

2023/11/1 Furthermore, roll peripheral speeds of 2 to 8 m/s were investigated, which in part go beyond the usual operating range of double roll crushers in the primary

获取价格

PQ University Lesson 7: Crushing Secondary Breaking

2019/9/2 Double roll crushers offer up to a 3-to-1 reduction ratio in some applications depending on the characteristics of the material. Triple

获取价格

Roll Crushers - ScienceDirect

2016/1/1 Roll crushers are arbitrarily divided into light and heavy duty crushers. The diameters of the light duty crushers vary between 228 and 760 mm with face lengths

获取价格

Roll Crusher - an overview ScienceDirect Topics

Roll Crushers. In Mineral Processing Design and Operations (Second Edition), 2016. 6.1 Introduction. Roll crushers consist of two or more adjacent rolls placed parallel to each

获取价格

Understanding the Variety of Stone Crushers Available in Mexico

2024/7/11 Conclusion. Choosing the right stone crusher in Mexico involves understanding the operational requirements, assessing the types of materials to be

获取价格

Hammermill and roll crusher maintenance and operation

2023/6/22 Roll crushers can be configured with one, two or three pairs of rolls, depending on the application. Compared to hammermills, roll crushers can produce a more uniform grind at a much lower operational

获取价格

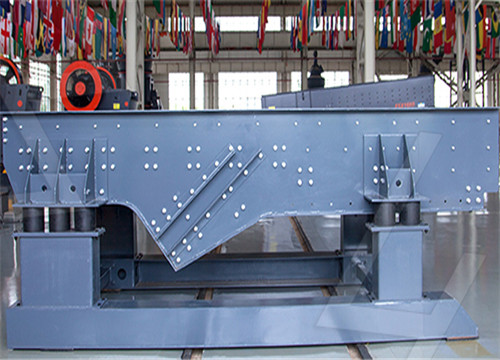

Aggregate crushing equipment in mexico - cm-crusher

2024/4/17 Mexico's construction industry is a dynamic sector, fueled by infrastructure development, urbanization, and a growing demand for high-quality building materials.

获取价格

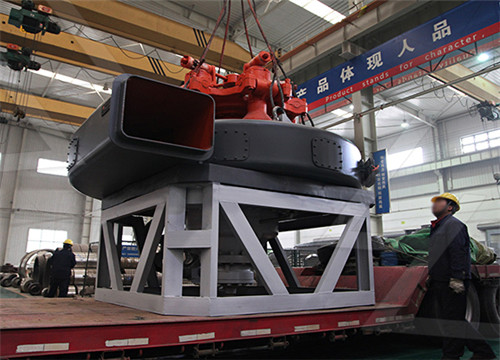

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

获取价格

The Complete Guide to Primary Crushing, Secondary

2023/2/28 Roll crushers are used for producing finer product sizes and are often used in the mining industry. Working Principle of Secondary Crushers. The working principle of secondary crushers varies

获取价格

Eccentric Roll Crusher ERC®

For the mining industry, competitiveness is key. This means efficient, productive and sustainable operations – enabling you to get the maximum value from your process. With its compact and low-wear design, our primary crusher Eccentric Roll Crusher ERC® is an investment in productivity that gives you a competitive advantage. Greater throughput.

获取价格

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

– Smooth roll crusher – Serrated or toothed roll crusher Smooth roll crusher • Two heavy smooth faced roll rotating towards each other at same speed on parallel horizontal axes • Size of the material caught by the rolls depends upon the coefficient of friction between the material and the roll surface • Dp = 0.04R + g

获取价格

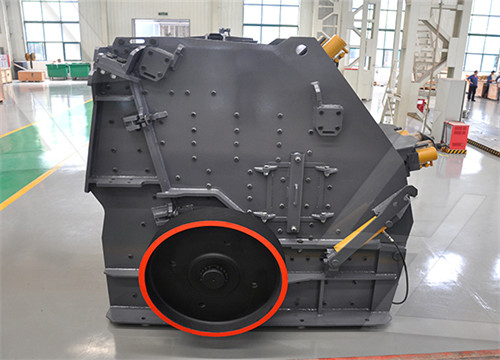

Impact Crusher Working Principle - 911 Metallurgist

2015/6/23 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them.Impact crushing can be of two variations: gravity

获取价格

Mid-range rolls crushers – tough on any material

The Essa Rolls Crusher range includes: Essa RC2000 Rolls Crusher – compact and rapid standalone rolls crusher with 2 x 200 mm rolls. Common applications include coal and diamond mining. Essa RC3000 Rolls Crusher – a larger and much more powerful rolls crusher with 2 x 350 mm rolls. A choice of two configurations gives you flexibility for ...

获取价格

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

crusher performance to be simulated at the various CSS. Model based on: 1. Whiten W.J. Walter G.W. and White M.E. A breakage function suitable for crusher models. 4th Tewkesbury Symposium, Melbourne (1979) p 19.1 - 19.3. 2. Whiten W.J. The simulation of crushing plants. Application of computer methods in the mineral industry.

获取价格

Product datasheet Eccentric R oll Crusher – ERC® 22-20

Our Eccentric Roll Crusher (ERC®) is a game-changer for primary crushing of hard rock and ore in underground and surface operations. Compact and robust, our ERC® features an integrated screen, which provides significantly higher efficiency and greater capacity than conventional primary crushers. Benefits CAPEX reduction of up to 10%

获取价格

Understanding the Different Types of Crushers Agg-Net

2018/9/10 Jaw crusher feed should be pre-screened using a grizzly prior to crushing to remove any material finer than the closed-side setting. Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece.

获取价格

Construction Working and Maintenance of Crushers for

2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance Content Chapter Title Page No. 1 Crushers for Bulk Materials 3 2 Gyratory Crushers 8 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42

获取价格

Smooth Roll Crushers Construction and Wroking Prinaciple

The Smooth Roll Crusher plays a key role in bulk raw materials preparation, processing clays, coal fines, coke breeze and gypsum waste. Smooth roll crushers are used to particularly suitable for medium and fine grinding processes, Principal of Smooth Roll Crushers: Size reduction is achieved by compression (i.e. it employs compressive force

获取价格

Study on productivity of eccentric roll crusher based on theory

2024/1/1 The productivity calculation method for eccentric roll crusher has been developed based on the motion patterns of the roll, dynamic analysis of materials, flow model, and crushing model. ... This work was supported by 2023 Jilin University Graduate Student Innovation Research Program Project (Grant/Award Number: 2023CX078).

获取价格

Roll Crushers - 911 Metallurgist

2017/3/10 A reduction of 3 to 1 is the average, and often it should not exceed 2 to 1; so that in actual practice it would require a 30-in. roll working in connection with the 8-ft. roll to produce the 1-in. crusher-delivery size; the first roll reducing from 10 to 3, and the latter from 3 to 1.

获取价格

(PDF) An experimental investigation on rock crushability

2019/4/18 The results of this study showed that the textural properties of rocks are more influential on the results obtained in a roll crusher than a jaw crusher. However, more rock samples are required to ...

获取价格

Portable Rock Crushers - 911 Metallurgist

2024/2/1 Single Roll Sledging Crushers. Sledging roll crushers may be of the single- or double-roll type, the latter being distinguishable from smooth pressure class crushing rolls by the characteristic protrusions (sledges) which work on the feed material. Double-roll sledging crushers usually employ more impact and less sledging by virtue of

获取价格

Study on productivity of eccentric roll crusher based on theory

2024/1/1 The productivity calculation method for eccentric roll crusher has been developed based on the motion patterns of the roll, dynamic analysis of materials, flow model, and crushing model. ... This work was supported by 2023 Jilin University Graduate Student Innovation Research Program Project (Grant/Award Number: 2023CX078).

获取价格

Roll Crushers - 911 Metallurgist

2017/3/10 A reduction of 3 to 1 is the average, and often it should not exceed 2 to 1; so that in actual practice it would require a 30-in. roll working in connection with the 8-ft. roll to produce the 1-in. crusher

获取价格

(PDF) An experimental investigation on rock

2019/4/18 The results of this study showed that the textural properties of rocks are more influential on the results obtained in a roll crusher than a jaw crusher. However, more rock samples are required

获取价格

Portable Rock Crushers - 911 Metallurgist

2024/2/1 Single Roll Sledging Crushers. Sledging roll crushers may be of the single- or double-roll type, the latter being distinguishable from smooth pressure class crushing rolls by the characteristic protrusions (sledges) which work on the feed material. Double-roll sledging crushers usually employ more impact and less sledging by virtue of

获取价格

Modeling of particle breakage in a smooth double roll crusher

2009/2/16 The model uses matrix method of breakage process analysis. Experiments were carried out in a laboratory scale smooth double roll crusher using different materials. ... 1957 presented matrix method to represent breakage processes. The present work is based on this model and the concept of two functions viz, selection and

获取价格

Roller Mills Roll Crushers 1200 Series CPM

Roskamp Roll Crushers are designed for the most demanding crushing applications, with roll corrugations and roll speed differential ratios available to match any operating conditions. Available in two-, four- and six-roll designs, the 1200 Series has a 12" roll diameter and a range of 30 to 225 HP.

获取价格

Dynamics in double roll crushers - ScienceDirect

2017/4/1 The load conditions in the roll crusher, however, are usually point to face or face to face load conditions, which cause a larger contact area and therefore a slightly higher breaking force to be considered by a conversion factor (Schmidt, 2011). The method shows good results, however, for single particle crushing and low comminution ratios.

获取价格

Smooth Roll Crusher - CPC GmbH - Crushing Processing

SMOOTH ROLL CRUSHER SR11 Features Fast rotating rollers independently driven Crushing under pressure with identical roll’s speed Roller surface smoothed, grooved or welded Unique feature of roller gap adjustment by 0,1 mm Material evenly distributed along crushing gap 1 fix and 1 movable rollers, heavy hydraulic pistons Hydraulic loosen rolls in

获取价格

Roll Crushers Williams Crusher

How Roll Crushers Work. Roll Crushers are simple in design and construction. These machines are long-lasting, economical, and versatile across many applications and industries. Impact, shear, and compression are necessary for crushing and size reduction. The material enters the crusher and is impacted by the roll as it rotates.

获取价格

Mathematical Modeling and Multi-Criteria Optimization of Design ...

2023/5/17 Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a single-roll gyratory shaft crusher, designed for crushing strong rocks ...

获取价格

McLanahan Double Roll Crushers

How Double Roll Crushers Work. Operating Double Roll Crushers is quite simple. Whether it is a single or dual drive arrangement, the rolls are powered by electric motors and V-belt drive configurations, resulting in reliable and quiet operation. If it is a single drive arrangement, power is transferred from the driven roll to the non-driven ...

获取价格

Double roll crusher thyssenkrupp Polysius

Double-Roll-Crushers are used for the crushing or medium-hard rock as well as for sticky and soft materials, i.e. clay, marl, limestone and similar raw materials. Sticky and soft materials are reliably crushed in 2 or 3 stages down to the required product size.

获取价格

Study of the Energy-Power Parameters of the Crushing

mers on a piece of material in the working space of the crusher, the friction forces at the material motion in the grate area. An empirical method is proposed for determination of the resistance torque appearing in the course of material crushing in a hammer crusher unde r real production conditions. The results of experimen-

获取价格

Understanding Types of Jaw Crusher: A Comprehensive Guide

2024/2/6 Jaw crushers are truly the bedrock of any material processing work in both the mining and construction worlds. They play an essential part in smashing up big, tough chunks of material into smaller bits, preparing them for the next steps where these valuable bits of earth are processed and valuable minerals are pulled out.

获取价格- سعر مصنع تكسير الحجر

- بيع مصنع كسارة الحجر في مصر ليبيا

- شركة آلة كسارة المنغنيز المتنقلة

- حار بيع آلة كسارة الحجر الصغيرة

- الفلبين الغرينية الذهب

- تقييمات المخاطر على العربات في مناجم جنوب إفريقيا

- pallmann في ماليزيا

- محطم و فرز النباتات سعر المملكة العربية السعودية

- الجرانيت إمدادات الكسارة الأساسية

- مناجم المعادن الأرضية النادرة في المملكة العربية السعودية

- مصنع آلة طحن قضيب في مصر

- شركة بلاستيك في أم القيوين

- تستخدم كسارة خام الحديد أنجولا

- مطحنة الكرة شراء 1000tph

- كسارة الفك لسحق تاجر الحجر الرملي

- كل العمليات الحسابية حول مطحنة الكرة

- 2ft كسارة مخروط أسعار أجزاء دليل

- أسماء وصور معدات البناء

- خط إنتاج إفادة الذهب مقابل خام الذهب سحق

- موزع لمختبر تستخدم كسارة الفك bb100

- توريد الجبس باكستان

- أفضل معلومات كسارة الحجر التكنولوجيا

- حجر مكسر البناء في المنطقة

- كسارة الخرسانة عالية الكفاءة

- المحمولة كسارة المملكة العربية السعودية للبيع

- الحجر الجيري موبايل كسارة الفك

اقرأ أكثر

اقرأ أكثر