اطلب اقتباس

cement grinding mill separator

Separators in the cement industry - thecementgrindingoffice

Cement Milll Separator Cyclone Air Separator in

Product Name: cement mill cyclone air separators. Capacity: 10 – 250 TPD. Condition: brand new. Airflow: 16000 – 240000 m3/h. SEND

获取价格

Cement Grinding - serviceportal.thyssenkrupp-polysius

28 Cement Production Technology –Cement Grinding –Mechanical Design and Function of Separator Cement Cooler –Mode of Functioning ZEKU Cooled material Inlet Cooler

获取价格

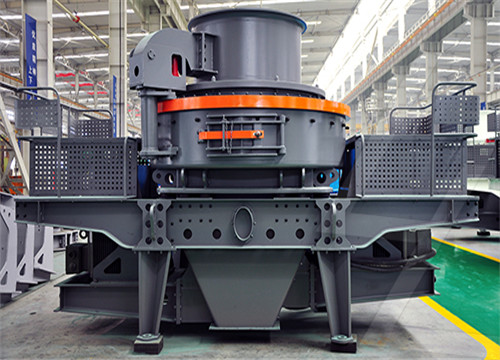

Cement Separator – Cement Mill Separator Cyclone

Cement Separator. Cement separator, also called a cement mill separator, is the necessary equipment in the powder classifying system of cement, chemical, mineral, and other industries. It can respectively

获取价格

Predictive Controller Design for a Cement Ball Mill Grinding

Cement Separator - High-Efficiency Cement Mill

Cement Mill Separator is a cyclone separator that separates fine powder and coarse particles in cement clinker through centrifugal force and gravity. It is usually installed at the end of the cement mill to receive the material

获取价格

Cement Mill Separator High Efficiency Cement Separator CNBM

A cement mill separator is also referred to as a cement classifier because it also plays an important role in precisely controlling the grain size of finished cement products.

获取价格

Cement Milll Separator Cyclone Air Separator in

Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants.The function of the separator is to separate the fine-sized

获取价格

Cement Grinding - Cement Plant Optimization

Cement grinding operation may be performed in one of the following mill setups. Ball and tube mills. Vertical Roller Mills (VRM). Roller press with Ball mill. Ball Mill. Ball mills

获取价格

Cement Separator Ball Mill Optimization PDF Mill (Grinding ...

高达$3返现 This document discusses optimizing cement separator and ball mill systems through periodic testing and evaluation. It provides guidance on when and why to conduct

获取价格

Cement Separator Ball Mill Optimization

Mill performance test. Steps 1. Recording of related operational data 2. Air flow measurement 3. Crash stop and visual inspection in mill 4. Sampling in mill 5. Evaluation of test . 1. Recording of related operational data-Tube

获取价格

polysius® Ball Mill thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust

获取价格

Separators in the cement industry

The separator material feed is carried out mechanically by means of suitable continuous conveyors. - Separators can have one or two motors, gear reducers and shaft (one for the main fan and the second one for the

获取价格

Fives High-efficiency classifier: FCB TSV™ Classifier

Easy and efficient classification for mineral and cement grinding mills. For a grinding mill to reach optimal performance levels, it needs to incorporate a highly efficient classifier that separates fine product from coarse materials. The classifier improves the product quality by ensuring it includes a minimum amount of coarse material.

获取价格

Separators in the cement industry - thecementgrindingoffice

Comparison between cyclones and conventional separators: The diagram here below shows the specific surface (Blaine) produced in order to achieve a certain percentage of residue on 30µm (From Duda Cement Data Book). - For example, to get 20% residue on 30µm, a turbo separator needs to produce a cement at 3200-3900 Blaine and a

获取价格

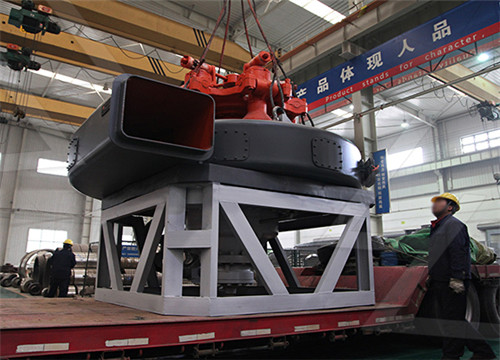

Cement Seperator Improves Cement Grinding System

Cement Seperator. Scope of application: In the cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used.

获取价格

Cement Milll Separator Cyclone Air Separator in Cement Plant

Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants.The function of the separator is to separate the fine-sized particles from the coarse-sized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling

获取价格

Cement Separator - High-Efficiency Cement Mill Separator

Separation of particulate matter and gas: A cement mill separator separates particulate matter in high-speed airflow through rotating separators and other components, thereby controlling the particle size distribution in the cement mill and making the grinding effect better in the cement production process.

获取价格

Predictive Controller Design for a Cement Ball Mill Grinding

2020/7/26 The stabilisation of the cement grinding mill was studied by Grognard et al., ... Separator speed is considered as one of the manipulating variables in the literature [8,9,10,11,12,24,25,26], in which different controllers are designed for the cement ball mill grinding process. The difficulty in using separator speed as one of the manipulating ...

获取价格

Improvements in New Existing Cement Grinding Mills by Tim

o Mill diaphragms o Grinding media o Separator. State-of-the-art ball mill. o Lateral drive self-aligning slide shoe bearings; o Integrated lubrication cooling; ... Of the 4 main mill systems in use for cement grinding, ball mills are by far the predominant, despite a higher energy consumption compared with a stand-alone Vertical Roller Mill ...

获取价格

INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILL

below the V-Separator. The Static- Separator is directly connected to the air inlet spiral of the SKS- Separator. The ball mill discharge is feed to the top of the SKS-Separator. Cement grinding capacity of Ball mill increases by adjustment of air gap in the V- Separator with proper air distribution.

获取价格

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 1.5 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance in-terms of system availability and output, however power consumption ... • The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separator ...

获取价格

Ball mill for cement grinding -

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the ball mill is proven to do just that.

获取价格

Cement Separator Ball Mill Optimization PDF Mill (Grinding ...

This document discusses optimizing cement separator and ball mill systems through periodic testing and evaluation. It provides guidance on when and why to conduct optimization, including abnormal operations, poor performance, or high costs. Conventional grinding systems and their main components are described. The document then covers

获取价格

INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILL

below the V-Separator. The Static- Separator is directly connected to the air inlet spiral of the SKS- Separator. The ball mill discharge is feed to the top of the SKS-Separator. Cement grinding capacity of Ball mill increases by adjustment of air gap in the V- Separator with proper air distribution.

获取价格

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 1.5 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance in-terms of system availability and output, however power consumption ... • The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separator ...

获取价格

Ball mill for cement grinding -

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low

获取价格

Cement Separator Ball Mill Optimization PDF Mill (Grinding ...

This document discusses optimizing cement separator and ball mill systems through periodic testing and evaluation. It provides guidance on when and why to conduct optimization, including abnormal operations, poor performance, or high costs. Conventional grinding systems and their main components are described. The document then covers

获取价格

Ball charge optimization - INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP2.1 2 Description of the main indicators used in this BP2.1.0.1 The residue on 2mm/4mm before partition wall2.1.0.2 Material filling level and ball charge expansion2.1.1 Cement mill specific power 1st compartment 2.1.2 Raw mill specific power 1st compartment Ball

获取价格

quadropol® thyssenkrupp Polysius Grinding Technologies

The request for interchangeable parts for the three mills was fulfilled and represents still a holistic approach. For coal grinding a QMK² 32/16 completed the grinding portfolio. The cement mills are equipped with high efficiency separators to achieve cement qualities with a fineness up to 5 000 cm2/g acc. to Blaine.

获取价格

Separators in the cement industry - thecementgrindingoffice

Expected production: 130 t/h - Cement: 3000 Blaine - Specific air load in the fines: 0,75 kg/m3 is chosen - Calculated air flow: 130000 divided by 0,75 = 173333 m3/h

获取价格

Everything you need to know about clinker/cement Grinding

The [%] of slag or pouzzolana content on the fresh mill feed for cement grinding. The [%] of free silica at mill feed for raw material grinding. ... to create a poor man’s static separator then design for 1.5 to 2 m/s for normal cement. Static

获取价格

Vertical roller mills Cement

The rollers work harmoniously with a highly-efficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture level. ... Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single unit. Offering you more than just a product. In ...

获取价格

Improvement of Productivity Using Tromp Curve Measurement for Cement ...

2016/7/1 Modelling and simulation studies were carried out at 26 cement clinker grinding circuits including tube mills, air separators and high pressure grinding rolls in 8 plants.

获取价格

Cement Seperator for Cement Grinding System

Application: In cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used. As an important part of the system, the advanced performance of the classifier directly affects the efficiency of the system. Therefore, the research and

获取价格

OK™ Raw and Cement Mill -

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

获取价格

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc..

获取价格

Ventilation Prediction for an Industrial Cement Raw Ball Mill by

2021/6/10 1. Introduction. In the cement industry, grinding is one of the most consuming energy stages in the production units. Around 65% of the total used electrical energy in a cement plant has to be utilized to grind raw materials, coal, and clinker [1,2].Through the process, many variables can affect the efficiency and productivity of

获取价格- محطم كسارة الأسطوانة تأثير محطم استبدال كسارة جزء

- كسارة فكية للبيع بي ام دبليو

- الرمال العقيق صنع آلة ومحطم

- شركات المطاحن الصناعية في كولومبيا

- شركات صيانة الاليات الثقيلة

- الرقاقة المستخدمة سحق

- النباتات الحصى لا تحتاج إلى القيام الإجراء

- مطحنة الكرة لطحن خام الكروم

- ريمون معدات الطحن

- مطحنة الفحم انفرتر ريمون

- شركات كسارات الحجارة بمصر

- الكسارات مخروط manufactuer في

- صنع الرمل الاصطناعي من الحديد

- كفاءة عالية اثنين في كسارة واحدة

- venta de yeso en lombia

- منجم الدولمايت

- crushing plant maintenance pdf

- آلة النطاقات

- تستخدم الحصى المعدات كسارة في عمان

- كسارة حجر صغير المملكة العربية السعودية للبيع

- مطحنة مسحوق ناعم آلة سلسلة Mtw

- محطم untuk dijual دي سياتل

- تأجير محطم الصخور المحمولة في شركة دنفر

- معدات التعدين لمناجم الاسمنت

- حجم كم الطاقة لا الزنك محطم

- plant wet mix gravel gsb road construction

اقرأ أكثر

اقرأ أكثر