اطلب اقتباس

Processing Plant With Hydroseparator In Magnetite Ore

Processing of Magnetite Iron Ores–Comparing

2009/1/1 An option study for a 10 Mt/a ore processing plant for a. consistently hard, fine-grained silica-rich magnetite ore was. carried out, with the emphasis on comminution circuit options. capacity of ...

获取价格

How to Recover Iron from Magnetite: 4 Methods and Stages

What Is Magnetite?Beneficiation Methods of MagnetiteComplete Magnetite Production LineMagnetite Ore Processing Plant The beneficiation process of magnetite mainly includes 4 stages. Once you have discovered or mined magnetite, you can extract iron concentrates through the following process. 1. ➢ Magnetite crushing and screening 2. ➢ Magnetite grinding and classification 3. ➢ Magnetite separation 4. ➢ Magnetite dehydration

Iron-Ore enrichment by magnetic hydroseparation - ResearchGate

2011/10/1 Abstract. The magnetic hydroseparator is described. Thanks to the replacement of magnetic separation drums by hydraulic separation, this new system for

获取价格

Eco-efficient and cost-effective process design for magnetite iron

Processing of Magnetite Iron Ores - Comparing Grinding Options

Both technologies are already implemented in some magnetite processing operations, although in limited capacity. The results of a theoretical option study for high capacity

获取价格

Processing of Magnetite Iron Ores–Comparing Grinding Options

The results of the analyses clearly shows that using a sieve of +180µm and its bottom -180µm, the best time for grinding 0.5kg of Itakpe iron ore with 3kg of grinding media and

获取价格

Developments in the physical separation of iron ore: magnetic ...

2015/1/1 They are first crushed and the coarse particles pretreated using roll magnetic separators. The magnetic product of roll magnetic separators may reach

获取价格

High Pressure Grinding Roll and Magnetic Separation for

Saving in Grinding and Simultaneously Improving Processing Capacity: A Case Study of a Magnetite Ore Jianwen Yu1,2,3 Yaxiong An 1,3 Peng Gao1,2,3 Yuexin Han 1,2,3

获取价格

5 Kinds of Magnetite Ore Processing Methods - Xinhai

2023/10/23 Magnetite is widely distributed in nature and is often found together with hematite and manganese ore. It has strong magnetic selectivity and is one of the main

获取价格

Developments in the wet and dry processing of lower grade

The results of early laboratory test work on the development of an efficient and environmentally sustainable dry processing option for the beneficiation of lower grade

获取价格

Optimising Western Australia Magnetite Circuit Design

The use of a hydroseparator is commonplace in plants with and without reverse silica flotation. This ... Reverese silica flotation is usually seen as a last resort when processing magnetite as there is a ... Typical magnetite ore will have an Ai of 0.25 or less. The

获取价格

Dry Permanent Magnetic Separator: Present Status and

Minerals 2022, 12, 1251 4 of 20 Figure 1. Schematic diagram of CT series magnetic pulley structure. 1—multipole magnetic system; 2—cylinder; 3—magnetic conductor; 4—belt [8].

获取价格

Beneficiation Processing of Magnetite ore from Lampung as

2024/7/3 Characterization by XRF and AAS gives Fe content of 46.6% and 48.8% for the first route product, and 52.1% and 52.9% for the second route. Lampung magnetite ore gives lower magnetism characteristic compare to Australian magnetite ore. Finer particle size gave lower magnetic saturation value, hence lower magnetism.

获取价格

Improve Mineral Processing Efficiency By Magnetic Separator

2024/8/14 Magnetic separator is the basic tool used by mineral processing plants to separate ferrous and non-ferrous metals from extracted ore, ensuring high-quality final products. Its works by attracting magnetic particles such as iron, steel and nickel, and then using powerful magnets or electromagnets to separate these particles from other materials.

获取价格

Mining separation and sorting equipment for processes in the mining

Mining separation - magnetic separation and sensor sorting solutions for improved throughput and recovery rates in ore sorting and mineral processing From traditional and trusted magnetic separation equipment, right through to innovative sensor sorting technologies, we help our customers achieve their goals with sustainable solutions.

获取价格

Upgrading the Fe Grade of Magnetite Concentrate Using a

Magnetite ore samples used for the research are from the slime s dam at Phalaborwa Foskor mine, South Africa. Foskor treats phosphate ore using flotation process and their tailings material contains 45 to 53% Fe in the form of magnetite. The magnetic ore sample used comprised of Silicon Oxide(1,0,1) Magnetite, syn (2,2,2), Hongquiite

获取价格

The Magnetic Separation Process for Ore Processing - Medium

2024/4/29 Applications of Magnetic Separation: The versatility of magnetic separation extends its application across various industries: 1. Iron Ore Processing: Magnetic separation is widely used in iron ...

获取价格

(PDF) Pilot Plant for the Processing of a Complex Tin Ore: A ...

2020/3/31 A dry magnetic separation by a drum type magnetic separator served as a case study to visualize effects of processing of a skarn ore with a high content of cassiterite as ore mineral (~4 wt%).

获取价格

Mineral and Technological Features of Magnetite ... - ACS

2021/3/24 Analysis of the current technical solutions for the processing of iron ores showed that the high-grade ores are directly exposed to metallurgical processing; by comparison, low-grade ores, depending on the mineralogical and material composition, are directed to beneficiation including gravitational, magnetic, and flotation processes or

获取价格

Dry beneficiation of iron ore - Mineral Processing

Fig. 4 shows the process stages of a possible iron ore beneficiation for magnetite ores or also siderite and taconite ores that have only a low to medium iron content. After comminution and screen sizing, the coarse ore and fine ore streams are treated separately. The coarse ore stream is fed to a DMS trommel and then wet screen classification.

获取价格

DRY MAGNETIC SEPARATION OF MAGNETITE ORES ScienceGate

At the Magnitogorsk steel-works crushing and concentration plant No. 5 this range is from 50 mm up to 15 mm. To determine the optimal ore size, delivered to DMS, studies accomplished to determine the specific magnetic susceptibility of the magnetite and the burden for the magnetite ore of Maly Kuibas deposit. ... Peculiarities of fine magnetite ...

获取价格

High Pressure Grinding Roll and Magnetic Separation for

2024/5/31 Lean magnetite resources in China are characterized by low iron grade, fine embedded particle size, complex composition, etc., which can only be utilized through complex beneficiation processes [1,2,3].With the increasingly serious problems of low-grade, fine iron minerals, and difficult-to-treat ore properties, the required particle size of ore

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格

Iron ore magnetite processing - alsglobal

Iron ore magnetite processing (LIMS, MIMS, WHIMS, Davis Tubes) The increased worldwide demand for steel in recent decades has led to an increase in the exploitation of magnetite iron ore deposits as an alternative to hematite DSO ores. Magnetite concentrate is a higher-grade product than hematite and very desirable as a smelter feed.

获取价格

DRY MAGNETIC SEPARATION OF MAGNETITE ORES ScienceGate

At the Magnitogorsk steel-works crushing and concentration plant No. 5 this range is from 50 mm up to 15 mm. To determine the optimal ore size, delivered to DMS, studies accomplished to determine the specific magnetic susceptibility of the magnetite and the burden for the magnetite ore of Maly Kuibas deposit. ... Peculiarities of fine magnetite ...

获取价格

High Pressure Grinding Roll and Magnetic Separation for

2024/5/31 Lean magnetite resources in China are characterized by low iron grade, fine embedded particle size, complex composition, etc., which can only be utilized through complex beneficiation processes [1,2,3].With the increasingly serious problems of low-grade, fine iron minerals, and difficult-to-treat ore properties, the required particle size of ore

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格

Iron ore magnetite processing - alsglobal

Iron ore magnetite processing (LIMS, MIMS, WHIMS, Davis Tubes) The increased worldwide demand for steel in recent decades has led to an increase in the exploitation of magnetite iron ore deposits as an alternative to hematite DSO ores. Magnetite concentrate is a higher-grade product than hematite and very desirable as a smelter feed.

获取价格

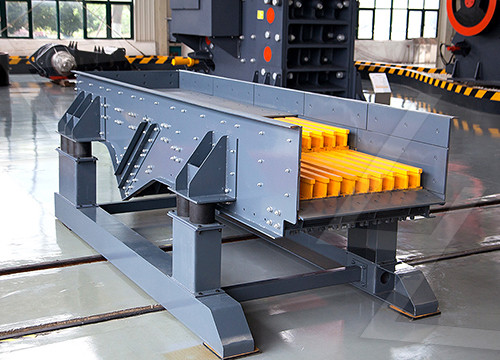

Magnetic separation process,Iron magnetic separation plant,Magnetic ...

It is also called iron magnetic separation plant, magnetic mineral processing plant and magnetic plant. Advantages of Iron Magnetic Separation Plant: This joint method leads to 90 % ore utilization. It can save water as well as costs. Magnetic dust is collected by dust collecting devices, which will not cause air pollution.

获取价格

Assessing the performance of a novel pneumatic magnetic separator for ...

2020/9/1 Invariably, low-grade magnetite ores processing warrants further beneficiation, after crushing and ... deposits located in these arid regions usually requires an extensive water pumping infrastructure such as desalination plant ... D., 2009. Trends in Magnetite Ore Processing and Test Work. In: Iron Ore Conference, 27 - 29 July, Perth ...

获取价格

Simulation assisted performance improvements in iron ore processing plants

2009/2/1 For reliable simulation of taconite processing plants, mathematical models for the magnetic separator, hydroseparator and fine screens were developed, incorporated into Usim Pac mineral processing ...

获取价格

Hypothetical magnetic iron ore separation process flow sheet

Also, the reclamation of stockpiled material simultaneously with the mining operation increased the total ore tonnage as well as maintaining the average head grade required by the processing plant.

获取价格

Minerals Free Full-Text A Novel Pneumatic Planar Magnetic

2020/8/27 In our previous studies, we investigated the performance of a novel pneumatic planar magnetic separator (PMS) for the dry beneficiation of a selected magnetite ore. In the present study, we have extended the studies on the PMS with the focus on investigating how various PMS processing flowsheet configurations influence

获取价格

sbm/sbm processing plant with hydroseparator in magnetite ore

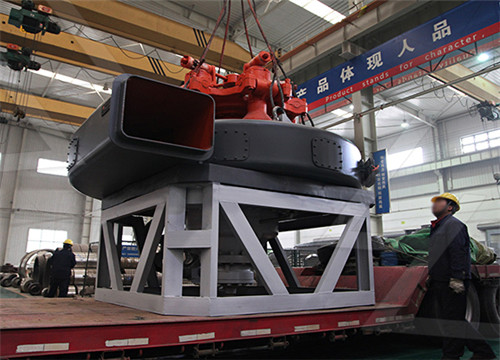

sbm processing plant with hydroseparator in magnetite oreMagnetite Iron Ore Processing Plant Suppliers Sponsored Listing Magnetite Iron Ore Beneficiation Plant Mineral Processing Yantai Xinhai offers turnkey solutions for Magnetite Iron Ore Beneficiation Plant.Specialized in the fabriion of these machines for18 years and this

获取价格

magnetite separator, magnetite iron ore processing, magnetite ...

After 20 years practice, Xinhai Magnetite Separation Production Line reduces the production line cost by improving separation equipment. Hotline: 0535-6300668

获取价格

Magnetite Concentration Methods - 911 Metallurgist

2018/2/6 At Port Orem, New Jersey, the New Jersey Iron Mining Co. is operating a magnetic-concentration plant on magnetite ores. The ore carries magnetite in stringers and grains in a gangue of quartz and some finely disseminated apatite. It is crushed in breakers and rolls to a size varying from 20 mesh to ¼ in., depending upon the ore treated.

获取价格

Mineral and Technological Features of Magnetite–Hematite Ores

2021/4/4 The magnetite–hematite ores of the Mikhailovskoye deposit are characterized by fine dissemination of ore and gangue minerals, the complexity of the structural and textural features and material composition, a low-level contrast in the magnetic properties of the separated minerals, and so forth. 28−30 The content of iron

获取价格

(PDF) Dry Permanent Magnetic Separator: Present Status

2022/9/30 With the depletion of global iron ore resources, a dry, low-cost processing or pre-sorting prior to the wet separation has received the attention of industrial practitioners as a potential ...

获取价格- كسارة حجر الجرانيت هيدروليكي مخروط محطم

- تخطيط ستو شمال شرق محطم في مصر

- سعر بيع كسارة خام النحاس

- تستخدم معدات البناء تركيا

- كسارة كاملة كوارتز

- الانتصاب أمبير ماينتينسي صيانة

- سوق المعدات الثقيله في مصر المنصوره

- شاشات الخامات

- الات صنعية في صين

- التعليم الطبي المستمر مخروط اومني محطم

- لمحة عن الشركة لطاحونة

- كيفية اصلاح ماكينات طرح الأسفلت vogele super 1800

- كيفية عمل مصنع الجرانيت

- شراء كسارة الحجر في guade

- الكسارات المتنقلة المحجر

- babcock 8 e9 خدمة مطحنة الكرة الهند

- محرك ديزل صغير سعر كسارة

- سحق MAQUINA مصنع الجرانيت والرخام

- النقل من الصين C3A7C3A3o

- ميكانيكا محطم

- آلات طحن الحصى المحمولة

- مصنع مطحنة الخليط في gobindgarh

- الصين معدات سحق الحجر برمودا

- كسارة الفك خطط غربلة كسارة مطحنة

- سعر كجم آلة طحن

- Grinding Media Inc

اقرأ أكثر

اقرأ أكثر