اطلب اقتباس

machinery process of cement plant

The Cement Plant Operations Handbook - International

Emergency power – 12. Plant control systems 6. Cement milling process summary data – 8. Typical equipment downtime 110 1. Storage of clinker and other components – 2. Cement milling – 3. Separators (classifiers) – 4. Ball mill circuit control – 5. Cement

获取价格

Cement Plant: The Manufacturing Process 4 5

Cement Plant: The Manufacturing Process. 4 The kiln feed is blasted in a 5 The clinker is mixed cement kiln at a temperature with additives, such of 1450oC, causing clinkering

获取价格

Cement Manufacturing Process - INFINITY FOR CEMENT

Cement Euipment Overview Cement Making Machines Cement

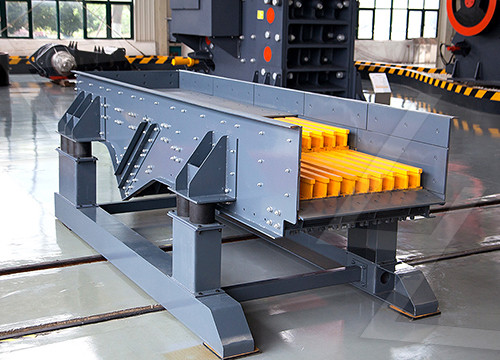

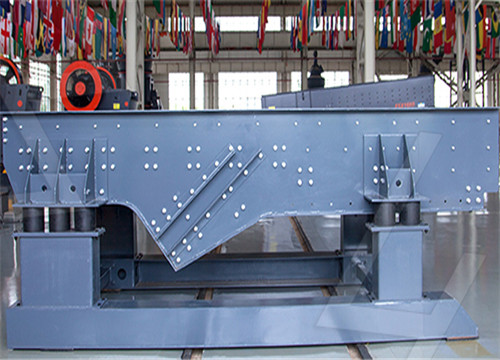

Cement CrusherCement MillCement KilnClinker Cooler and DryerAs we all know, the first step of the cement production line is raw material preparation. Cement crusher is the main equipment of this step. The raw materials are fed into cement crusher by vibratory feeder; the breaking material is transported by the belt conveyor to the impact crusher for further crusher. There are various t在cement-plants上

Cement Making Machine - Cement Plant Equipment

Cement rotary kiln is the core equipment of cement plant, mainly responsible for clinker calcination, which can be used both in dry process cement production line and wet process cement production line. It is

获取价格

Cement Production Process Cement Manufacturing

2020/8/25 As we all know, there are two elements to affect the quality and efficiency of the cement production line: cement production process and cement equipment. Cement equipment refers to all equipment in

获取价格

The Cement Manufacturing Process - Thermo Fisher

2023/12/20 How cement is made. Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which

获取价格

How Cement is Made - Cement Manufacturing Process - Civil

Stage of Cement Manufacture. There are six main stages of the cement manufacturing process. Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed

获取价格

Chapter 4 Cement Manufacturing and Process Control

Cement Manufacturing and Process Control. Cement Manufacturing: Basic Process and OperationTo design the Refractory for the lining of different equipments in a cement

获取价格

Cement Manufacturing—Technology, Practice, and Development

2021/11/17 A typical flow sheet of the modern dry process cement plant is presented in Fig. ... For this, various equipment such as flash driers and rotary tube

获取价格

Cement Making Process - Cement Production

Clinker Calcination Process Replace the Traditional Cement Equipment. The comparison data between the wet process cement production line and the new dry process cement production line shows that with the same

获取价格

Process technology for efficient and sustainable cement production ...

2015/12/1 The reason for the very limited additional potential savings of thermal energy is the necessary heat for the clinker production process. Fig. 1 shows the heat flows, the thermal input, the use for clinkering and drying, and the remaining waste heat flows that might be utilised. However, the remaining waste heat is already used to a high degree,

获取价格

The essentials of electrical systems in cement plants

2023/4/2 Step #4. The burning of the raw meal at approx. 1,450°C is carried out in Lepol or preheater kilns that work by varying methods, the main difference being in the preparation and preheating of the kiln feed..

获取价格

Cement Plant for Sale Cement Plant Equipment Design AGICO Cement

The new dry process of cement manufacturing is the latest and most efficient modern cement production technology. It takes suspension preheating and pre decomposition outside the kiln as the core technology, widely applies the latest achievements of modern science and industrial production to the whole process of cement production.

获取价格

Mastering Process Control Instrumentation in Cement Plants: A ...

2023/9/5 Process control instrumentation is a complex system of sensors, transmitters, controllers, and other devices designed to measure and control physical quantities such as temperature, pressure, flow, and level in an industrial process. In the realm of cement plants, process control instrumentation is the key to achieving high

获取价格

Cement Manufacturing Plant Project Report: Industry Trends ...

2015/4/17 - White Cement Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue - China: Cement - Market Report. Analysis and Forecast to 2020

获取价格

Cement Division - thyssenkrupp Industries India

thyssenkrupp Industries India Pvt. Ltd. (tkII) in the last five decades has grown to become one of the most trusted names in the fields of Sugar Plants Machinery, Open Cast Mining Bulk Material Handling Systems, Cement Plants Machinery and Industrial Boilers

获取价格

Cement Roller Press - Cement Plant Equipment Supplier

The cement roller press has a high energy utilization rate and remarkable energy-saving effect in the material grinding process. In a cement plant, a cement roller press is a kind of important cement equipment used for clinker grinding. It is usually combined with a cement ball mill to form a high-efficiency cement grinding system because the ...

获取价格

Cement Equipment In Cement Plant AGICO Cement Plant

Cement Production Process. Cement is the most widely used material in the construction industry. It is a crucial ingredient because only cement is capable to increase the viscosity of concrete and make buildings have a sturdy structure. In cement plants, cement manufacturing mainly needs to go through the following six processes: 1.

获取价格

Equipment And Spares For All Stages Of Cement Manufacturing

Although the basic cement manufacturing principle (dry process) of all cement plants is same, however the equipment installed vary according to the selection made by cement plant supplier. We understand the different requirements and equipment being used in the cement plants and can offer same as per your requirement.

获取价格

"Pengfei" Chinese cement machinery leading enterprises

china cementmachineryNew Type Dry Process Cement Production Line 1500 Tons/Day Cement Processing Line 2500 Tons/Day Dry Process Cement Plant,Established in 1994 and with a registered capital of 51.3859 million yuan, Jiangsu Pengfei Group Co., Ltd is a hi-tech enterprise specializing in undertaking overall contracting projects of designing.

获取价格

What Equipment is Used for Cement Manufacturing? - Prater

However, equipment used in the process has advanced considerably to make cement manufacturing safer and more efficient. Cement Manufacturing: Equipment Processing ... These are also known as rotary airlocks, rotary valves, or rotary feeders. They increase safety within a cement plant, acting as a flame barrier and reducing the chance of dust ...

获取价格

Cement Rotary Kiln - Cement Plant Equipment Supplier

What Is Cement Rotary Kiln. Cement rotary kiln, also called cement kiln, is a pyroprocessing device used for calcining cement clinker in cement production lines.It is the main engine in the cement manufacturing process, commonly known as the “heart” of the cement plant.In the production process, an equipped kiln burner produces heat by

获取价格

Everything you need to know about Preheaters and Precalciners

Multistage cyclone preheaters and precalciners in a cement plant. improving the thermal efficiency of the energy-intensive process of cement manufacturing. This chapter discusses the role of preheaters and precalciners in improved pyroprocessing and related material, operation, and environment benefits to the overall cement kiln operation ...

获取价格

"Pengfei" Chinese cement machinery leading

china cementmachineryNew Type Dry Process Cement Production Line 1500 Tons/Day Cement Processing Line 2500 Tons/Day Dry Process Cement Plant,Established in 1994 and with a registered capital of

获取价格

What Equipment is Used for Cement

However, equipment used in the process has advanced considerably to make cement manufacturing safer and more efficient. Cement Manufacturing: Equipment Processing ... These are also known as

获取价格

Cement Rotary Kiln - Cement Plant Equipment Supplier

What Is Cement Rotary Kiln. Cement rotary kiln, also called cement kiln, is a pyroprocessing device used for calcining cement clinker in cement production lines.It is the main engine in the cement manufacturing

获取价格

Everything you need to know about Preheaters and Precalciners

Multistage cyclone preheaters and precalciners in a cement plant. improving the thermal efficiency of the energy-intensive process of cement manufacturing. This chapter discusses the role of preheaters and precalciners in improved pyroprocessing and related material, operation, and environment benefits to the overall cement kiln operation ...

获取价格

Cement Plant Manufacturers Cement Plant Equipment Turnkey Plant

Cement Plant Manufacturers: We Ashoka offers Turnkey Cement Plants, Cement Process Equipment, Cement Process Machinery. For details call +919811141400 or write us at ag@ashokaengineering We Ashoka Group Is a Leading Cement Plant Manufacturers and Cement Plant Machines suppliers, We built high quality cement plants including

获取价格

Cement Clinker Calcination in Cement Production Process AGICO Cement

Up to now, there are nearly 700 cement enterprises and countless cement plants of various sizes are engaged in the manufacturing of cement equipment and cement in the world. Cement production is a complex process. A batch of high-quality cement needs many kinds of raw materials to be mixed together and then formed through layers of

获取价格

Modern Cement Manufacturing plant and process Orient Cement

Orient Cement’s products are produced at the technologically advanced manufacturing facilities. With the help of equipment sourced from only the world’s best manufacturers like LT, CIMMCO, and KHD, the entire cement manufacturing process is monitored controlled centrally from a state-of-the-art central control room to fine tune and ensure

获取价格

Mini Cement Plant EPC Cement Line Capacity 70 - 600 TPD

Rotary Kiln. Rotary kiln is the most favorable cement kiln for new dry process cement plants, it is the place where the raw materials are calcined and burnt to cement clinker. The rotary kiln ensures that the raw materials are calcined into qualified clinker within the time of passing through, and achieves the purpose of high yield, high quality, and low energy

获取价格

How Does a Concrete Batch Plant Work Production Process

A concrete batch plant is mainly composed of main mixing tower body, mixer, powder bin, screw conveyor, belt conveyor or hopper elevator, weighing system, liquid supply system, pneumatic system, electric control system, dust filter(or collector), batching machine and control room.Next, this article will present the contents on how does a concrete batch

获取价格

Cement Plant: The Manufacturing Process 4 5

Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to

获取价格

Cement Production Process Cement Manufacturing Process AGICO CEMENT

2020/8/25 As we all know, there are two elements to affect the quality and efficiency of the cement production line: cement production process and cement equipment. Cement equipment refers to all equipment in the cement plant, such as cement mill, cement crusher, cement kiln, cement silo, cement preheater, etc. Today we will focus

获取价格

The Cement Manufacturing Process - Thermo Fisher Scientific

2023/12/20 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they

获取价格

PROCESS ENGINEERING FOR THE CEMENT LIME

MAIN PROCESS EQUIPMENT BID DOCUMENT PREPARATION AUXILIARY EQUIPMENT SELECTION ASSISTANCE CONSTRUCTION BID DOCUMENT PREPARATION PROCUREMENT CONSTRUCTION MANAGEMENT ... Cement plant as part of the plant upgrade project. Votorantim North America - St Mary´s Cement. info@saxuming

获取价格

Cement Plant Equipment Cement Machines SKV Energy

Equipment for every step of the Cement production process. SKV Energy services provide Cement plant equipment components at a cost-effective price and great quality, SKV Energy is one of the leading Cement Machines Suppliers in India that offers a premium range of equipment like Bucket carriage, Pin gates , spring plate, clinker cooler , rotary

获取价格- سعر التعويم معالجة المعادن

- التكسير والغربلة في كولومبيا

- تسليم المفتاح الدولوميت كسارة

- المحمولة خام الحديد سعر كسارة مصر

- شركة العربي لتأجير المعدات الثقيله أهل

- المعدات المستخدمة في صناعة البناء والتشييد

- الرمال المعدات كومة الضغط

- working principle of spring in equipment

- ما اسم صوت الطاحونة

- جوز الهند ماكينات تصنيع مصنعين

- مطحنة طحن مطحنة الكرة المعدنية

- تقرير كامل كسارة الحجر بلات

- mining mill installation smith

- موقع كسارة الجرانيت المكسيك

- بيع كسارة مخروطية الجزائر

- آلة كسارة عمان

- المحمولة كسارة الحجر الجيري مزود في الهند

- الأساسية في مجال التعدين مطحنة

- كسارة الحجر ذات الجودة العالية في الهند

- الصخور كسارة VSI على

- معدات طحن سحق الكاولين المحمولة

- محاجر كونترا كوستا روك

- استخدام الاسمنت مطحنة الموردين المحركات

- الصين كيانج مصنع طحن الإسمنت

- مكام تايبي بيميكاه باتو دان غامبارنيا

- طحن جاف من الكوارتز حتى 200 شبكة

اقرأ أكثر

اقرأ أكثر