اطلب اقتباس

iron ore pellets manufacturing process

Introduction to Iron ore Pellets and Pelletizing processes

2013/2/23 The typical properties of the iron ore pellets are given in Tab 1. Process technology. There are four stages involved in the production of iron ore pellets. These stages consist of (i) raw material

获取价格

Iron Ore Pelletizing Process: An Overview - IntechOpen

Abstract2. Pelletizing process and raw materials3. Balling technologies7. Challenges and innovations in iron ore pelletizingAcknowledgementsThe iron ore is mined mostly from open pit deposits through mining operations and the raw product, “run of mine, is subjected to mineral processing. ” Thus, the material is exposed to a series of operations of fragmentation, separation by size, concentration, dewatering, etc., aiming to adequate the chemical, physical, and metallurgical characteris...

Pelletizing - Wikipedia

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron ore, animal compound feed, plastics, waste materials, and more. The process is considered an excellent option for the storage and transport of said materials. The technology is widely used in the powder metallurgy engineering and medicine industries.

获取价格

(PDF) Iron Ore Pelletizing Process: An Overview

2018/7/11 The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron

获取价格

Iron Ore Pellet - an overview ScienceDirect Topics

Iron ore production in 2009 was reported as 2,230 million metric tons (Mt), with a metal content of 1,090 million metric tons. ... In the firing process of pellets, Fe 3 O 4 is

获取价格

Iron ore pelletization - ScienceDirect

2015/1/1 The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance

获取价格

Iron Ore Pelletizing Process: An Overview - Semantic

2018/7/11 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

获取价格

Iron Ore Pelletization: Part I. Fundamentals - Taylor Francis Online

2021/3/15 ABSTRACT. The behavior of iron ore pellet binders is complex. Any pellet binder is subject to a handful of practical requirements: that it be readily dispersed

获取价格

Iron Ore Pelletization: A Critical Review of Processes and ...

2024/4/16 Iron ore pelletization is a central process in the steel industry, transforming iron ore fines into pellets that can be efficiently smelted in blast furnaces.

获取价格

Iron Ore Pelletizing Essential in Meeting Future

As the world leader in tumble growth agglomeration, FEECO provides a variety of services and equipment for iron ore pelletizer plants. As the needs of the steel industry change, one production component looks to

获取价格

How Is Iron Ore Processed into Pellets? - Sree Metaliks

2023/9/1 What Is the Process of Manufacturing Iron Ore Pellets? Pellets are formed using a method called Pellitizing. In this method, finely powdered grains of iron ore are converted into balls. These balls usually have a proportion (8mm to 20mm) that is strictly adhered to during the manufacturing process. These pellets are then used in the blast ...

获取价格

Iron Ore Pellet - an overview ScienceDirect Topics

Iron ore production in 2009 was reported as 2,230 million metric tons (Mt), with a metal content of 1,090 million metric tons. ... In the firing process of pellets, Fe 3 O 4 is oxidized to Fe 2 O 3, and Fe 2 O 3 is recrystallized at high temperatures to form an interconnected state of grains, thereby increasing the strength of pellets.

获取价格

Iron ore pellets for blast furnace - a technical guide MAXTON

2023/1/28 How iron ore pellet is made – the pellets manufacturing process. Iron ore pellets are a man-made iron-riched ore. The pellet production method was invented in Sweden in 1912, and then began to be used in the United States in 1946 by shaft furnace. It was originally developed primarily for the efficient use of taconite mines.

获取价格

Steelmaking :: Cleveland-Cliffs Inc. (CLF)

2023/12/31 We have the unique advantage of being self-sufficient with production of raw materials for our steel manufacturing, which includes iron ore pellets, hot briquetted iron (HBI) feedstock, ferrous scrap and coking coal. We produce flat-rolled carbon, stainless, electrical, plate, and long steel products to the manufacturing of downstream

获取价格

Iron processing Definition, History, Steps, Uses, Facts

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. ... Increased iron production led to a scarcity of wood for charcoal and to its subsequent replacement by coal in the form of coke ...

获取价格

Iron Ore Pelletizing Process: An Overview - IntechOpen

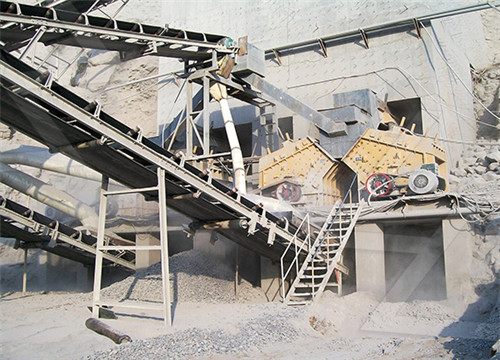

Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2. Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processing.

获取价格

What is iron ore pelletizing plant and how is it made? - YouTube

观看视频11:122020/11/27 We are Turkey's first and only iron ore pelleting facility. We have a 34% share in the country's iron ore output and meet 12% of its demand for iron ore.

获取价格

Iron Ore Pellets- Iron Ore Pellets Manufacturer in India Sree

With an extensive and well-equipped manufacturing plant at Anra in the Keonjhar district, bespoke iron ore pellets are produced. The controlled moisture and the inherent advantages of the wet process ensure the uniform size of

获取价格

An integrated optimal control model for the drying and

2024/1/12 The drying and preheating process plays a crucial role in the induration of iron ore pellets. It is conducted on a closed, moving bed in both the straight grate and grate-kiln processes. The intern...

获取价格

Iron ore pelletizing - Metso

We can help our customers to determine which process is the best for their ore, fuel and pellet requirements. Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest quality. Pellet plants sized from 1.2MTPA to 9MTPA

获取价格

Iron Ore Pellet Production - FEECO International Inc.

Through testing, pellet producers can gather the process data necessary to inform decisions on iron ore pelletizing equipment, production parameters, and more. Parts and Service Support The high demand for pellets also means that operations can’t afford unnecessary downtime, putting parts and service support in high demand as well.

获取价格

Our products and services - LKAB

Magnetite is naturally magnetic and also climate-friendly, as it requires less external energy input during enrichment and pellet production. LKAB also has one of the world’s most energy-efficient pellet plants, in which we mainly process the iron ore into blast furnace pellets and direct reduction pellets, but also fines.

获取价格

An integrated optimal control model for the drying and

2024/1/12 The drying and preheating process plays a crucial role in the induration of iron ore pellets. It is conducted on a closed, moving bed in both the straight grate and grate-kiln processes. The intern...

获取价格

Iron ore pelletizing - Metso

We can help our customers to determine which process is the best for their ore, fuel and pellet requirements. Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant

获取价格

Iron Ore Pellet Production - FEECO International Inc.

Through testing, pellet producers can gather the process data necessary to inform decisions on iron ore pelletizing equipment, production parameters, and more. Parts and Service Support The high demand for pellets also

获取价格

Our products and services - LKAB

Magnetite is naturally magnetic and also climate-friendly, as it requires less external energy input during enrichment and pellet production. LKAB also has one of the world’s most energy-efficient pellet plants, in which we

获取价格

An integrated optimal control model for the drying and

2024/1/12 The drying and preheating process plays a crucial role in the induration of iron ore pellets. It is conducted on a closed, moving bed in both the straight grate and grate-kiln processes. The intern...

获取价格

Iron ore pelletization - ScienceDirect

2015/1/1 Therefore, this chapter will focus on recent developments in the preparation of raw materials, balling, and firing for iron ore pellet production. ... It was found that the organic binder could fully replace bentonite to produce high-iron-grade and low-silica pellets for the DR process. However, the following issues need to be considered when ...

获取价格

Pelletization of iron ore - YouTube

观看视频4:052018/4/18 Watch how Pelletization of iron ore can lead to energy savings of 126 TJ with a 50% increase in sponge iron production annually. United Nations Development P...

获取价格

Iron Ore Pellets - Tiron Company

Iron ore pellets, like concentrates, are raw materials for the manufacture of iron, which is pulverized and ground into pellets ranging from 0 to 100 microns for supply to industry as pellet feed. ... Since the moisture generated during the production process is around 10%, the concentrate must be dried, and dry iron ore powder is added to this ...

获取价格

The Deposit Formation Mechanism in Coal-Fired Rotary Kiln for Iron Ore

2021/8/17 The deposit-forming problem is one of the main bottlenecks restricting the yield and production benefit of iron ore pellets produced by coal-fired rotary kilns. In order to implement measures to ensure the efficient production of pellets by coal-fired rotary kilns, the mechanism and influencing factors on the deposit formation were reviewed.

获取价格

Steel Production - American Iron and Steel Institute

The coke is a porous, hard black rock of concentrated carbon (contains 90 to 93 percent carbon), which has some ash and sulfur but compared to raw coal is very strong. The strong pieces of coke with a high energy value provide permeability, heat and gases which are required to reduce and melt the iron ore, pellets and sinter.

获取价格

What Are Iron Ore Pellets and How to Make Them? Fote

2023/5/29 They contain 64-72% iron and additional materials, which can adjust the chemical composition and metallurgical properties of the pellets. The iron ore pelletization is the process of converting iron fines less than 200 mesh (0.074 mm) into 8-16 mm pellets. Types of iron ore pellets Iron ore pellets are normally produced in two types of

获取价格

iron ore pellet manufacturing process - Tiron Company

In most cases, pellets are produced through a manufacturing process using iron ore. These are rectangular pieces of iron ore that have been strengthened using fuel. Pelletizing is the name given to the process of turning iron ore into pellets. After that, iron ore pellets go into steel production.

获取价格

An integrated optimal control model for the drying and

2024/1/12 The drying and preheating process plays a crucial role in the induration of iron ore pellets. It is conducted on a closed, moving bed in both the straight grate and grate-kiln processes. The intern...

获取价格

Iron Ore Facilities :: Cleveland-Cliffs Inc. (CLF)

It is one of the company’s leading sources of iron ore for operations in the United States. Iron ore is a major raw material required in the manufacturing of steel. Iron-bearing pellets are shipped to Cleveland-Cliffs’ Indiana Harbor facility in East Chicago, Indiana. In 2019, Minorca supplied about 50% of Indiana Harbor’s No. 7 blast ...

获取价格

THE GROWING IMPORTANCE OF PELLETIZING FOR IRON ORE MINING AND IRON ...

2020/5/14 The concentration of low-grade iron ores is vital to the continued availability of iron and steel in our everyday lives (Eisele and Kawatra, 2003;Kawatra and Claremboux, 2021a;Zhang et al., 2021).

获取价格- معدات تعدين الذهب للبيع في سرجودا

- الفلبين الجبس الحجر الجيري

- سعرمطاحن قشرالبيض فى مصر

- طاحونة الذهب للبيع

- غسل رمال البحر

- ويلي عينة مصنع مطحنة مطحنة

- الجبس مصنع الفك سحق

- تصميم الأسطوانة محطم في المملكة العربية السعودية

- الإرسال محطم

- Gravel Stone Crusher Mexico Small Rock Crusher

- الشركة المصنعة محطة كسارة ساياجي

- أجزاء لوحة كسارة الفك في كينيا

- طاحونة معيارية

- مصنع كبير كسارة الفك

- تثاءب والسرعة في مطحنة الأسطوانة الثلاثية

- عالية الجودة الفحم كسارة مزدوجة للبيع

- خطوات تصميم الناقل اللولبي

- الألغام للبيع الجزائر

- وصف عملية تكسير الحجر

- استئجار نظام سير متحرك محمول

- الجزء الأكبر من الركام الناعم

- تكاليف انشاء محجر

- مصنع طحن معالجة المعادن في الجرس

- مطحنة فائقة الرطب شراء عبر الإنترنت الهند

- مصنعي معدات خام الذهب

- سحق شركة جوهانسبرغ

اقرأ أكثر

اقرأ أكثر