اطلب اقتباس

top quality best sell mantle cover for cement plant cone crusher

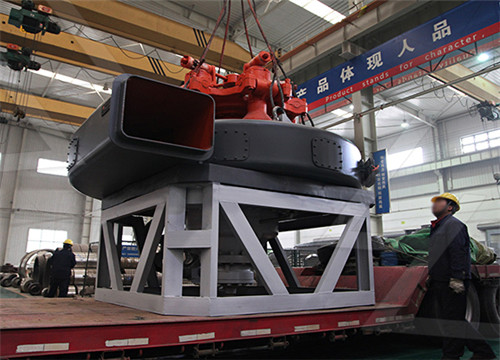

Cone Crusher Mantle For Sale – Cone Mantle Customizable

AGICO crusher mantle doubles the production efficiency of the cone crusher, and reduces investment costs and downtime losses caused by frequent replacement of accessories,

获取价格

Cone Crusher Mantle For Sale – Crusher Mantle Customizable

The cone crusher mantle is a critical element that combines protective and functional roles, contributing significantly to the overall efficiency and longevity of the cone crusher. Skip

获取价格

Concave And Mantle - crusher-stone

We pride ourselves on offering top-quality cone crusher concaves, mantles, and arm guards, crafted from manganese alloys in 14%, 18%, and 22% grades, enriched with

获取价格

Mantle Bowl Liner Premium Cone Crusher Liners - GTEK MINING

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: the mantle

获取价格

Cone Crusher Wear Parts Replacement - JXSC Mineral

2023/6/14 The cone crusher wearing parts include mantle, concave/bowl liner, bowl adapter ring, main frame liner, feed cone/hopper liner, torch rings and burning rings, eccentric bushings, adjustment rings,

获取价格

Cone Crusher Concave - Cone Crusher Bowl Liner For Sale AGICO

Cone crusher concave, also called cone crusher bowl liner, is the wear lining plate fixed on the upper part of the crushing chamber for protecting the upper accessories of the cone

获取价格

Cone Crusher Parts - JXSC Machine

The mantel, also known as the moving cone, covers the cone head to protect it from wear. The bowl liner is also called a cone crusher concave. The sacrificial wear liner sets inside the upper frame to protect the cone

获取价格

Mantle Cover - China Cone Crusher and Crusher - Made-in

2021/3/12 Company Introduction: Metsour is an industrial and trading company, a ISO9001 Certificated company, a professional Iron Casting Products supplier with 15

获取价格

Understanding the Cone Crusher Working Principle: How It

2023/2/23 The mantle and concave are two essential components of the cone crusher that play a critical role in the crushing process. The mantle is the cone-shaped part of the crusher that moves in a circular motion against the stationary concave, which is the outer surface of the crusher. The gap between the mantle and concave is called the

获取价格

Cone Crushers (Parts of a Cone Crusher) Explained

Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism

获取价格

Different Types Cone Crusher For Selection DASWELL

Cone crusher machine is mainly composed of cone crusher mantle, conehead, cone crusher liner, eccentric sleeve, main shaft, dustproof cover, frame, hydraulic cylinder and other cone crusher parts. When the cone crusher is working, the motor powers the transmission device, which can drive the eccentric sleeve to rotate.

获取价格

Types of Crushers: What You Need to Know

It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force. The crushed material is first broken down at the top of the cone where they then fall down into a lower part of the cone that is more narrow. At this point the cone crusher crushes the material again into an even smaller size.

获取价格

Selecting the right crusher for your operations - Quarry

2020/3/19 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing. First, cone crushers cannot accept all material sizes. Any material fed to the crusher must be pre-sized for that particular crusher (usually 200mm or less).

获取价格

Cement Crusher Crushers for Cement Plant AGICO Cement

Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing. Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, water conservancy, transportation, and other industrial fields.

获取价格

Cone Crusher: Pengertian, Fungsi, Jenis dan Cara Perawatannya

2023/12/29 3. Cone Crusher Gyratory. Cone Crusher Gyratory memiliki rongga penghancur yang berbentuk kerucut tetapi berputar secara eksentrik. Ini memberikan efek penghancuran dengan gerakan yang lebih kompleks dibandingkan jenis lain. Cone Crusher Gyratory umumnya digunakan dalam skala industri besar dan memiliki kapasitas yang

获取价格

Cone crushers - for demanding crushing needs - Metso

® HP Series™ cone crushers. ® HP Series™ is the most popular cone crusher family in the world with over 10,000 machines sold globally. ® HP Series™ cone crushers are well performing and reliable rock crushing machines for all aggregates production, quarrying and mining applications.

获取价格

Cone Crusher Mantle For Sale – Cone Mantle Customizable

Working Principle. When the cone crusher is working, the crusher concave is fixed, and the crusher mantle and movable cone not only make slow rotational motion, but also make lateral stroke motion with the eccentric bush so that the large pieces of material are continuously crushed by compression, impact, and bending in the annular crushing

获取价格

Understanding Cone Crusher Parts Names, Functions, and

2023/2/22 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance. It covers various types of cone crusher parts, common issues and solutions, and future developments in the industry. Whether you are in the market for a new cone

获取价格

Cone Crusher Spare Parts Top 10 OEM Manufacturer Bowl Liners and Mantle ...

Description. Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.. And the bowl liner which is also known

获取价格

The Complete Guide to Primary Crushing, Secondary Crushing,

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of

获取价格

What is a cone crusher mantle? – Sandrock Mining

2021/6/11 Cone crusher concave and mantles are the main factors that determine the size of the discharge opening. When the cone crusher is under load, concave, mantle and the stone make circular motions, causing wear, so it is necessary to adjust concave and mantle gap to control the granularity of the finished product.

获取价格

Cone Crushers – MEKA

CONCRETE BATCHING PLANTS Ready Mix Concrete Plants Stationary Concrete Batching Plants Mobile Concrete Batching Plants Compact ... What is a Cone Crusher? Cone crushers comprise two main parts: a fixed conical body that narrows toward the top, and a movable cone at the top that is mounted on an eccentric shaft through the center

获取价格

Cone Crusher Spare Parts Top 10 OEM Manufacturer Bowl Liners and Mantle ...

Description. Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.. And the bowl liner which is also known

获取价格

The Complete Guide to Primary Crushing, Secondary

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working

获取价格

What is a cone crusher mantle? – Sandrock Mining

2021/6/11 Cone crusher concave and mantles are the main factors that determine the size of the discharge opening. When the cone crusher is under load, concave, mantle and the stone make circular motions,

获取价格

Cone Crushers – MEKA

CONCRETE BATCHING PLANTS Ready Mix Concrete Plants Stationary Concrete Batching Plants Mobile Concrete Batching Plants Compact ... What is a Cone Crusher? Cone crushers comprise two main parts: a fixed conical body that narrows toward the top, and a movable cone at the top that is mounted on an eccentric shaft through the center

获取价格

Understanding the Cone Crusher Working Principle For Right

2023/2/21 The cone crusher is one of the most popular and commonly used crushing equipment in quarries, mines, and other industries. It is designed to crush materials with high hardness and medium hardness, such as basalt, granite, limestone, gravel, quartz, iron ore, copper ore, and so on.

获取价格

Stone Crusher and Cone Crusher Manufacturer in Gujarat, India

In the mining, iron and steel, and quarry sectors, crusher machines are used to crush a wide range of materials. a device that employs mechanical force to reduce large stones, chunks of concrete, or other construction materials into smaller chunks with a

获取价格

Cone Crusher Liners: How to Select and When to Change

2020/6/23 Cone Crushers were developed more than a century ago to provide secondary, tertiary and even quaternary material reduction.. Like other compression crushers, Cone Crushers feature a crushing chamber or cavity where the rock is crushed to a smaller size.The crushing chamber in a Cone Crusher is the space created between

获取价格

Everything you need to know about Crushers in Cement industry

The hammer crusher with feed rollers (F.L.S) is a special form of construction to avoid complicated, multi-stage crushing, a hammer has been developed, which does not require preceding primary crushing. This crusher reduces rock lumps from 2 m size down 25 mm. The crusher uses a single hammer rotor with peripheral speed of about 40 meters per ...

获取价格

Mantle Bowl Liner Premium Cone Crusher Liners

The mantle covers the cone head to protect it from wear; we can see it as a sacrificial wear liner that sits on the cone head. The bowl liner, also known as concave, is the sacrificial wear liner that sets inside the upper frame to protect the upper accessories of

获取价格

Raptor® Cone Crushers for Mining and Aggregate -

Raptor® cone crushers 3 Reliable: Rock solid performance. Our Raptor cone crusher spare parts are designed to offer . excellent performance with increased durability, smoother . operation and reduced maintenance expenses. We keep your essential equipment running. Structural Integrity. The critical load bearing components of the Raptor cone

获取价格

What Is a Cone Crusher and What Can It Do for You?

2021/1/10 Eagle Crusher recently unveiled its own offering of Raptor® cone crushers at CONEXPO-CON/AGG 2020, North America’s largest construction trade show. Our team is currently offering the 250, 350, and 450 model Raptor® cone crushers for customers. If you are interested in a cone crusher, please contact a Team Eagle sales

获取价格

Impact Crusher - Impact Rock Crusher AGICO Cement Plant

In the working process of the machine, the rotor rotates at a high speed driven by the motor. When materials enter the crushing chamber, they will be impacted and crushed by the blow bar on the rapidly turning rotor, and then thrown to the impact plate for a secondary breaking, finally rebounded back to the rotor area and be crushed again.

获取价格

Cone Crusher - Cone Crusher manufacturers - Crusher Mill AGICO

The cone crusher is suitable for the medium crushing and fine crushing of ores or rocks whose compressive strength limit is below 300 mpa. It is widely used in the fields of mining, metallurgy, silicate, and other industries, and is generally engaged in the second and third stages of the crushing process in cement plants.According to the different crushing

获取价格

Hammer Crusher Working for Cement Plant AGICO CEMENT

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a

获取价格- الصين منتج خبث فرن الفرن

- price of double sided grinder

- كسارة تصادمية 10 tph

- كسارات اسطوانة واحدة في مصنع تلبيد

- غسالة الرمال للبيع السعودي الألومنيوم جزيره العرب

- موثوق بها الفك محطم سلسلة البورصة

- مطحنة المطرقة البديل من Raymond

- معدات التعدين سحق

- المحاجر المعدات أوغندا

- مخروط crusherhpc

- القانون الفلبيني لسنة محكمة استئناف البليتون

- سعر ضاغطة القمامة

- بالموجات فوق الصوتية الهوائية للالطاحن الوقود السائل

- تهتز آلية شاشة هزاز

- سنگ شکن سنگ در غیر

- مراحل طحن الدقيق فى مطاحن بغداد والموص

- الموردين من كسارة الحجر الآلات في المملكة العربية السعودية

- خطوات تعدين النحاس

- معدات سحق من المملكة العربية السعودية

- آلات كسارة حجر الفك الشركات في الهند

- أجزاء كسارة مساعدة

- جديد النسر مصنع المحمولة مع محطم

- أفضل شاشة الحصى ومحطم خط المعالجة

- بحث عن وظائف فى مصر توزيع كتالوجات القا

- Concrete Crushers For Rent In Florida

- مخطط الحجر الجيري المسحوق

اقرأ أكثر

اقرأ أكثر