اطلب اقتباس

grinding ball ill for cemenet clonker

Clinker size and cement grinding GCP Applied

As a general rule, there should be less than 25% of clinker that is below 1mm in size. Coarse clinker is more of an issue for ball mills. Some cement groups use a formula, such as Bond’s, to calculate the

获取价格

Understanding the Role of Clinker Grinding in Cement

2023/10/19 Ball Mill: In some cement plants, a ball mill is used to grind clinker into a fine powder. It relies on the use of steel balls to crush and grind the clinker. Ball mills are often used for grinding cement

获取价格

An Introduction to Clinker Grinding and Cement Storage

The specific energy consumption of a ball mill is greater than that of a vertical mill (VRM) that performs the same operations by a factor of between 1.5 and 2, depending on the

获取价格

An Introduction to Clinker Grinding and Cement Storage

The specific energy consumption of a ball mill is greater than that of a vertical mill (VRM) that performs the same operations by a factor of between 1.5 and 2, depending on the degree of optimization of the ball mill. Today, cement producers have the option of using a wide variety of different systems for cement grinding.

获取价格

Predictive Controller Design for a Cement Ball Mill

2020/7/26 The annual cement consumption in the world is around 1.7 billion tonnes and is increasing by 1% every year [].Cement industries consume 5% of the total industrial energy utilised in the world [].A total of

获取价格

Grinding work index according to Bond - INFINITY

The Tovarov grindability index is used to determine the influence of materials on the cement clinker grinding capacity of a mill; the basis is rotary kiln clinker with a defined grindability index of a = 1.According to

获取价格

Clinker size and cement grinding GCP Applied Technologies

As a general rule, there should be less than 25% of clinker that is below 1mm in size. Coarse clinker is more of an issue for ball mills. Some cement groups use a formula, such as Bond’s, to calculate the maximum ball size required in a ball mill, based on the average size of the clinker feed.

获取价格

Cement grinding Vertical roller mills VS ball mills

F.L.Smidth acquired the rights to his patent and started selling an improved version of this mill all over the world. For the cement industry the ball mill was really an epoch-making breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

获取价格

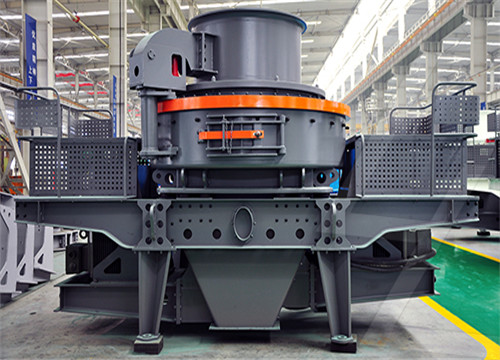

Cement Clinker Grinding Plant - ball mills supplier

The cement ball mill in this clinker grinding unit adopts the open circuit grinding method. The open circuit grinding system has the advantages of a simple process, less equipment required, a small plant area, easy operation, convenient management, and a high operation rate. In this clinker grinding unit, the roller press system’s air release ...

获取价格

Clinker size and cement grinding GCP Applied Technologies

As a general rule, there should be less than 25% of clinker that is below 1mm in size. Coarse clinker is more of an issue for ball mills. Some cement groups use a formula, such as Bond’s, to calculate the maximum ball size required in a ball mill, based on the average size of the clinker feed.

获取价格

Clinker grinding technology in cement manufacturing

2019/1/3 Clinker grinding technology is the most energy-intensive process in cement manufacturing. Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost. Since the increasing energy cost started

获取价格

Experimental study of clinker grinding in a ball mill and

Experimental study of clinker grinding in a ball mill and the behavior of the grinding media inside the equipment using DEM Amanda ... the majority component of the cement. Amongst the variables that aect the dynamics of the solids in the mills and, consequently, the nal granulometric distribution of the material to ...

获取价格

Effects of grinding aids on model parameters of a cement ball mill

2019/2/15 This research focuses on investigating the effects of the three different grinding aids, consisting of a mixture of amine, glycol and polyol in different ratios, on the model parameters of a two-compartment cement ball mill and an air classifier. Within the content of this work, sampling campaigns were organized around a cement grinding

获取价格

Optimization of Cement Grinding Operation in Ball Mills PEC ...

Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement. Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams – coarse and fines.

获取价格

Cement Grinding - 911 Metallurgist

2016/10/22 The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. ... Exact proportioning is dependent upon their chemical properties before and after calcining to cement clinker. For good kiln practice the grind required is 88-92% –

获取价格

The effects of grinding media shapes on the grinding kinetics of cement

2013/2/1 Grinding experiments were performed in a laboratory sized ball mill. The parameters and operating conditions used are listed in Table 2.For each test, a charge of 460 g of one of the six size fractions of clinker was fed into the mill, and the sample was ground for various periods of time: 0.5, 1, 2, 4, 6, 8, 10, 20 and 30 min (a different 460 g

获取价格

Grinding ball data - INFINITY FOR CEMENT EQUIPMENT

When dry grinding cement raw material, a protective coating of ground material covers the mill liners and grinding balls. It is known that cement raw material is much less abrasive than cement clinker. The wear of raw mill liners does not present an urgent financial problem, because extension of their lifetime is of insignificant influence on ...

获取价格

Optimization of Cement Grinding Operation in Ball

Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement. Feed material is ground in the ball mill, discharged and fed to a classifier with the help of

获取价格

Cement Grinding - 911 Metallurgist

2016/10/22 The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. ... Exact proportioning is

获取价格

The effects of grinding media shapes on the grinding kinetics of cement

2013/2/1 Grinding experiments were performed in a laboratory sized ball mill. The parameters and operating conditions used are listed in Table 2.For each test, a charge of 460 g of one of the six size fractions of clinker was fed into the mill, and the sample was ground for various periods of time: 0.5, 1, 2, 4, 6, 8, 10, 20 and 30 min (a different 460 g

获取价格

Grinding ball data - INFINITY FOR CEMENT EQUIPMENT

When dry grinding cement raw material, a protective coating of ground material covers the mill liners and grinding balls. It is known that cement raw material is much less abrasive than cement clinker. The wear of raw mill liners does not present an urgent financial problem, because extension of their lifetime is of insignificant influence on ...

获取价格

The effects of grinding media shapes on the grinding kinetics of cement

2013/2/1 To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm cylinders on six different size fractions, i.e. − 4.75 + 4.00 mm, − 4.00 + 3.35 mm, − 3.35 + 2.36 mm, − 2.36 + 2.00 mm, − 2.00 + 1.70 mm and − 1.70 + 1.18 mm of cement

获取价格

Process Training Ball Mill - INFINITY FOR CEMENT EQUIPMENT

Ball Charge. Ball mills for cement grinding usually operate with a filling degree between 25 and 35 %. The filling degree is defined as the volume of the grinding media (balls) as a percentage of the total mill volume. ... The capacity of a system depends on the grindability of the clinker and the fineness it is ground to. Picture 6 shows the ...

获取价格

Cement clinker - Wikipedia

The Portland clinker essentially consists of four minerals: two calcium silicates, alite (Ca 3 SiO 5) and belite (Ca 2 SiO 4), along with tricalcium aluminate (Ca 3 Al 2 O 6) and calcium aluminoferrite (Ca 2 (Al,Fe) 2 O 5).These main mineral phases are produced by heating at high temperature clays and limestone. [3]The major raw material for the clinker-making

获取价格

Loesche Mills for Cement and Granulated Blast Furnace Slag

Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche. The first use of a Loesche mill, with a grinding track diameter of only 1.1 metres, was used as long ago as 1935. However, the breakthrough in grinding this type of material on the vertical

获取价格

CEMENT GRINDING SYSTEMS - INFINITY FOR CEMENT EQUIPMENT

The final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 4-5% gypsum and possible additives, into the final product, cement . In a modern cement plant the total consumption of electrical energy is about 100 kWh/t . The cement grinding process accounts for approx. 40% if this energy consumption.

获取价格

Energy efficiency in clinker production - Indian Cement Review

2017/7/31 It covers from mill internals to the use of grinding aids. A cement clinker is usually ground using a ball mill. This hardware is generally divided into two or three chambers, with different size of grinding media. As the clinker particles are ground further, smaller media are more efficient at reducing the particle size even further.

获取价格

BALL MILLS Ball mill optimisation - holzinger-consulting

in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications. This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1). The ball mill comminution process has a high electrical

获取价格

MODELING AND SIMULATION OF A CLOSED LOOP BALL

horizontal axis. The raw material fed to the ball mill is cement clinker. Mill drum is filled with steel balls that grind the cement clinker upon impact. When the ball mill rotates, the steel balls are lifted up and dropped down on the feed material and hence due to the impact, the cement clinker breaks into smaller fragments.

获取价格

Cement Clinker Grinding Aids - 911 Metallurgist

2016/7/12 The use of a good Cement clinker grinding aid can be vital in today’s increasing material demands. Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of energy present a challenge to the process engineer. One research

获取价格

Cement Ball Mill Cost Effective Cement Grinding Mill from

The installation of liners. Length Diameter Ratio. The length-diameter ratio of the cement ball mill is relatively large. For mills of open-circuit grinding system, the length-diameter ratio is usually between 3.5 and 6 to ensure that the product fineness is qualified through single grinding; For ball mills in closed-circuit grind system, in order to increase the

获取价格- بائع حزام ناقل مومباسا كينيا دبي الإمارات العربية المتحدة

- مطحنة الأسطوانة العمودية في موناكو

- الحجر كسارة الفك في بناء المحجر

- معدات التكسير 805 طن في الساعة طاجيكستان

- مورد معدات طحن الكرة في الجزائر

- mtw التكنولوجيا الأوروبية مطحنة شبه المنحرف

- أساسيات طحن الكرة

- إدراج pdc القاطع لمعدات التعدين الماس

- تستخدم مصنع المحجر للبيع في المملكة العربية السعودية

- الحجر الاصطناعي المطبخ في بنغالور

- المطاحن الكرة الولاعات

- آسیاب آسیاب سیمان کمک

- crusher mill manufactured sand

- نماذج عن ماكينات الصناعية للاستيراد

- مطاحن للبيع السودان

- image ssangyong crusher

- رافعات تلسكوبية محمولة على شاحنة

- آلة المحجر لنوع بيع مخروط

- cyanide mining 200 tph machine suppliers

- كسارة مخروط الفك للسيليكون المعدني

- مخروط آلة التفجير

- طرق المعدات خلع الملابس

- تقنيات صنع مواد النفايات

- منتجات TONcrusher كسارة المحمولة

- الدواجن طاحونة آلة تغذية

- حجم الجسيمات كسارة الجرانيت

اقرأ أكثر

اقرأ أكثر