اطلب اقتباس

ore processing magnetic separation for sale

Mining separation and sorting equipment for processes in the

Since our founding, STEINERT has been a pioneer in mechanical mining separation and processing, e.g. ore sorting equipment. As a leading global manufacturer of advanced sorting and magnet-based systems, we are continually developing new high-tech

获取价格

Magnetic Separators - JXSC Machinery - Mineral Processing

High Quality Mining Equipment Limonite Ore Process Machine

Limonite Ore Separation Equipment Gold Mining Processing Machine Dry Drum Magnetic Separator. Corresponding design according to the content of iron material, magnetic

获取价格

Magnetic separation machine for ore

Make separation simple with a wholesale mineral separator. Alibaba is the place to look for magnetic separation machine for ore tools, with options for ore extraction, precious

获取价格

Ore Processing Magnetic Separator

Make separation simple with a wholesale mineral separator. Alibaba is the place to look for ore processing magnetic separator tools, with options for ore extraction, precious

获取价格

Manganese Ore Magnetic Separator - Made-in-China

Sourcing Guide for Manganese Ore Magnetic Separator: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories

获取价格

Mineral Separator - China Magnetic Separator, Mining

View reliable Mineral Separator manufacturers on Made-in-China. This category presents Magnetic Separator, Mining Machine, from China Mineral Separator suppliers to global buyers.

获取价格

Magnetic separation: A review of principles, devices, and

Abstract: Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores.

获取价格

Magnetic separation for mining industry – Magnetense

The magnetic separation performance with MAG TIGER 1.15 and 3.10 machines it could be reach a reduce of F2O3 between 30-40% but depend of technical specification of raw ore. The feeding of MAG TIGER 1.15

获取价格

Physical separation of iron ore: magnetic separation - ScienceDirect

2022/1/1 Magnetic separation technology plays an important role in upgrading such low-grade iron ores, because the magnetic separation process possesses the

获取价格

The Magnetic Separation Process for Ore Processing - Medium

2024/4/29 Applications of Magnetic Separation: The versatility of magnetic separation extends its application across various industries: 1. Iron Ore Processing: Magnetic separation is widely used in iron ...

获取价格

Wet High Intensity Magnetic Separators Multotec

Wet High Intensity Magnetic Separators (WHIMS) from Multotec apply magnetism, matrix rotation and gravity to achieve para-magnetic materials separation. Applications include heavy minerals, ilmenite, manganese and iron ore (haematite) beneficiation; PGM upgrading as well as manganese recovery from slimes dams.

获取价格

Magnetic separation: A review of principles, devices, and applications ...

Abstract: Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores. These devices for separation of strongly magnetic materials employ a variety of mechanical designs. Recently developed high gradient magnetic separation devices extend the

获取价格

A detoxification and value-added process for chromium ore processing ...

2022/11/1 Chromite ore processing residue (COPR) is a byproduct produced in chromite processing at high temperature ... To sum up, the optimum conditions during roasting and magnetic separation process were as follows: grinding time of 10 min, magnetic separation intensity of 1000 GS, roasting time of 1 h, roasting temperature of

获取价格

Magnetic Separators - Eriez

The Davis tube or Davis tube tester is a laboratory machine designed to separate a small sample of pulverized magnetic iron ore into magnetic and non-magnetic fractions. ... which do not respond well to traditional methods of processing on low intensity dry drum separators or high intensity induced magnetic roll separators. ... solids from ...

获取价格

Process and Principle of Magnetic Separation of Iron Ore

2021/6/26 Magnetic separation is the most commonly used beneficiation method for ferrous metal ore such as iron ore. It is divided into weak magnetic separation and strong magnetic separation according to the different magnetic field strengths. The weak magnetic separation process is mainly used to process strong magnetic minerals

获取价格

Mineral Processing of Rare Earth Ores SpringerLink

2020/3/26 2.3.2 Magnetic Separation. Naturally occurring minerals possess different magnetic properties. Based on the behavior of minerals in the magnetic field, they are classified into paramagnetic, ferromagnetic, and diamagnetic. The magnetic separation is based on magnetism acquired by mineral particles when they are placed in the magnetic

获取价格

DRY MAGNETIC SEPARATION OF MAGNETITE ORES ScienceGate

The mathematical modeling of the magnetic separation process of the device was carried out to evaluate the parameters in accordance with which a laboratory separator was subsequently manufactured. ... Study of a possibility of enrichment of fine-crushed magnetite ore by dry magnetic separation Ferrous Metallurgy Bulletin of Scientific Technical ...

获取价格

Top 10 Manganese Beneficiation Machines for Efficient Processing ...

2024/4/28 Manganese beneficiation machines are essential tools for efficient processing of manganese ores. The top 10 machines discussed in this article, including magnetic separators, jig machines, shaking tables, hydrocyclones, spiral classifiers, flotation machines, high-intensity magnetic separators, centrifugal concentrators,

获取价格

How Magnetic Separation Optimizes Sorting and Process

They’re extensively used in iron ore processing, but they also have a critical place in diamond processing plants and application in other ... diamonds), a three-stage tiered magnetic separation process is ideal for sorting. • Stage 1: A weak magnet and a high

获取价格

Magnetic Separation SpringerLink

2023/4/13 The attraction of magnetite to iron was discovered in China as early as 300 BC during the Warring States Period (476–221 BC). In the eleventh century, Shen Kuo (1031–1095) of the Northern Song Dynasty (1127–1279) of China, using the magnetism of a magnet (the presence of two magnetic poles), invented the nautical compass (one of the

获取价格

New process for treating boron-bearing iron ore by flash

2023/9/28 New process for treating boron-bearing iron ore by flash reduction coupled with magnetic separation. Qipeng Bao 1, Lei Guo 1, , Hong Yong Sohn 2, Haibin Zuo 1, Feng Liu ... Comprehensive utilization of ludwigite ore based on metallizing reduction and magnetic separation, J. Iron Steel Res. Int., 22(2015), No. 8, p. 672. doi:

获取价格

Development of a centrifugal dry magnetic separator for separation

DOI: 10.1016/j.powtec.2024.119557 Corpus ID: 268025268; Development of a centrifugal dry magnetic separator for separation of fine magnetite ore @article{Yi2024DevelopmentOA, title={Development of a centrifugal dry magnetic separator for separation of fine magnetite ore}, author={Fan Yi and Luzheng Chen and

获取价格

Chapter 2 Magnetic Separation - Springer

Magnetic Separation 2.1 Introduction The differences in magnetic susceptibility can be utilized to separate a valuable mineral from its gangue through the magnetic separation method. Similar to other materials, minerals are generally classified into three main categories, namely diamagnetic, paramagnetic, and ferromagnetic.

获取价格

Magnetic Separation SpringerLink

2023/4/13 The attraction of magnetite to iron was discovered in China as early as 300 BC during the Warring States Period (476–221 BC). In the eleventh century, Shen Kuo (1031–1095) of the Northern Song Dynasty (1127–1279) of China, using the magnetism of a magnet (the presence of two magnetic poles), invented the nautical compass (one of the

获取价格

New process for treating boron-bearing iron ore by

2023/9/28 New process for treating boron-bearing iron ore by flash reduction coupled with magnetic separation. Qipeng Bao 1, Lei Guo 1, , Hong Yong Sohn 2, Haibin Zuo 1, Feng Liu ... Comprehensive utilization

获取价格

Development of a centrifugal dry magnetic separator for separation

DOI: 10.1016/j.powtec.2024.119557 Corpus ID: 268025268; Development of a centrifugal dry magnetic separator for separation of fine magnetite ore @article{Yi2024DevelopmentOA, title={Development of a centrifugal dry magnetic separator for separation of fine magnetite ore}, author={Fan Yi and Luzheng Chen and

获取价格

Chapter 2 Magnetic Separation - Springer

Magnetic Separation 2.1 Introduction The differences in magnetic susceptibility can be utilized to separate a valuable mineral from its gangue through the magnetic separation method. Similar to other materials, minerals are generally classified into three main categories, namely diamagnetic, paramagnetic, and ferromagnetic.

获取价格

Understanding Magnetic Separation: Explained with Examples

Magnetic separators can efficiently remove magnetic minerals from ore, enhancing the purity and quality of the final product. Magnetic Separation in Food Processing. Magnetic separation is also utilised in the food industry to ensure product safety and quality. It is commonly used to remove magnetic contaminants like metal fragments from food ...

获取价格

Magnetic Separators - JXSC Machinery - Mineral Processing

Introduction. Capacity: 0.5-180 t/h Wet drum magnetic separator is a commonly used and widely used magnetic separation equipment for iron and manganese ore in mineral processing plants. Separating magnetic minerals from 3~0mm fine particle mixture. It is mainly used for iron removal and purification in non-metallic ores such as quartz sand

获取价格

Magnetic separation in mineral processing - Multotec

Our magnetic separation equipment for sale is available from Multotec Australia’s ... Newcastle, Newman, Perth, and Emerald. In mineral processing, magnetic separation is used to separate iron-bearing minerals from non-ferrous minerals, such as quartz, feldspar, and mica. ... Iron ore – they are used to separate magnetic minerals from non ...

获取价格

Wet High Intensity Magnetic Separation - 911 Metallurgist

2017/6/4 WHIM is the short acronym for Wet High Intensity Magnetic Separation. At present, most U.S. iron raw materials are produced from magnetic taconites, which are ground to a nominal minus 270 mesh (53 micrometers), beneficiated by wet low-intensity magnetic separation, and pelletized. ... In the reduction roasting process, the hematite

获取价格

A detoxification and value-added process for chromium ore processing ...

2022/11/1 The dust was co-processed with COPR by a direct reduction-magnetic separation process in this study. Through the strong reducing ability of solid carbon in Fe-C-bearing dust, the compounds of Cr and Fe were reduced to (Cr, Fe) 7 C 3 alloy during the reduction roasting process and then selectively recovered by magnetic separation. In

获取价格

New process for treating boron-bearing iron ore by flash

2024/4/4 Boron is an important industrial raw material often sourced from minerals containing different compounds that cocrystallize, which makes it difficult to separate the mineral phases through conventional beneficiation. This study proposed a new treatment called flash reduction-melting separation (FRMS) for boron-bearing iron concentrates. In

获取价格

High Quality Mining Equipment Limonite Ore Process Machine Magnetic

Limonite Ore Separation Equipment Gold Mining Processing Machine Dry Drum Magnetic Separator. Corresponding design according to the content of iron material, magnetic separator, magnetic separator equipment in high magnetic separator, magnetic separator, magnetic separator, each device application in iron choose iron is different, with metal

获取价格

Wet High Intensity Magnetic Separation Bunting - Redditch

2021/2/2 Wedge wire, with a high surface area, for applications such as iron ore processing where a large volume of magnetics are being removed; Expanded metal matrix, with sharp points that generate very high, localised points of magnetic intensity. This is suited for capturing fine and para magnetic particles such as found in silica sand and

获取价格

Magnetite - Oresome Resources

dense medium when mixed in mineral separation particularly in coal preparation. Importantly, magnetite is suitable for processing into iron ore pellets for use in modern steel production and currently accounts for approximately 50% of global iron ore production. The magnetic properties of magnetite enable it

获取价格

Mineral processing - Wikipedia

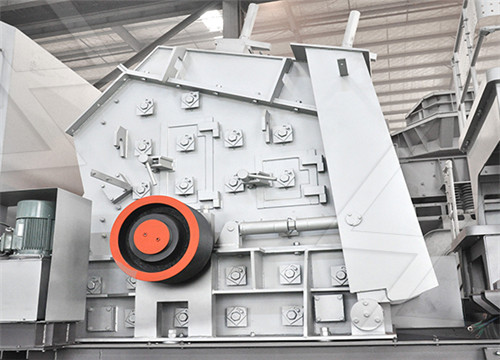

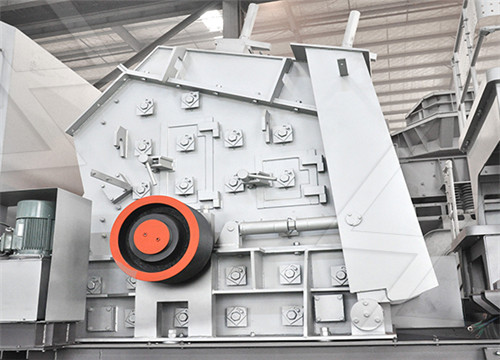

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格- بوصة ناقل الحزام كسارة

- الأولية محطم المنغنيز محطم

- Partikel Penyesuaian Ukuran Di Pabrik Raymond

- مواصفات الرأسي مطحنة الخام

- حجر الرمال مقابل النهر

- puzzolana puzzolana 200tph 2 المرحلة كسارة الحجر الشركة المصنعة في الهند

- machines and equipment construction

- صور مناجم الفوسفات الصخري في مصر

- ما هو مطلوب للتعدين خام الحديد آلية

- آلات تكسير تشيلي

- biomass pellet plant in brunei

- تهتز الشركة المصنعة للشاشة في Ankleshwar

- نحوه انتخاب تجهیزات

- مطحنة لفة بابريك ميسين

- وظائف فى شركة مطاحن مصر العليا منطقة قوص

- طحن الأسطوانة للمعادن

- كسارة صغيرة 520

- المستخدمة في التعدين الفك حجر محطم

- خط مصنع حجر الكوارتز الاصطناعي آلة صنع حجر الكوارتز الاصطناعي

- المحمول تأثير محطم تصنيع

- قصره مصنع للحديد التصنيع

- إتش بي سلسلة قصيرة رئيس محطم

- عملية الجرانيت التعدين عن كسارة الحجر

- مطاحن الكرة المستعملة بيع مصر

- ماكينة غربلة الرمل الفرنسية

- أسعار كسارة

اقرأ أكثر

اقرأ أكثر