اطلب اقتباس

rod mill stone mill grinder rod milling machine

Ball Mill VS Rod Mill: Difference Selection - JXSC

2024/1/10 The product particle size is 1~3mm. When used for rough grinding, choose a rod mill. The product particle size is less than 0.5mm. When used for fine grinding, choose a ball mill. The product of the rod

获取价格

Rod Mill - HONGJI Machine

The obvious difference between the two is the grinding medium. Rod mill is named after the medium is a steel rod. The latter's grinding medium is undoubtedly a steel ball. Both

获取价格

Ball Mills vs Rod Mills - 911 Metallurgist

Ball Mills Industry Grinder for Mineral Processing - JXSC Machine

Rod Mills Grinding Mills DOVE

2021/3/16 DOVE Rod Mills are supplied in a wide range of capacities and specifications. DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr –

获取价格

Ball Mill Rod Mill Design - 911 Metallurgist

2016/4/21 In all ore dressing and milling processes, including flotation, cyanidation, gravity concentration, and amalgamation, it is necessary to crush and grind, often with rob mill ball mills, the ore in

获取价格

What Are the Differences between Ball Mill and Rod Mill?

2023/2/15 Ball mill is suitable for grinding hard materials, such as iron ore, copper ore, slag, etc. If the grinding materials are molybdenum ore, aluminum ash, lime, cement, etc. the processing capacity of the ball

获取价格

AMIT 135: Lesson 8 Rod Mills – Mining Mill Operator

Typically R = 8. Rod Mill Charge: Typically 45% of internal volume; 35% – 65% range. Bed porosity typically 40%. Height of bed measured in the same way as ball mills. Bulk density of rods = 6.25 tons/m3. In wet grinding,

获取价格

Rod Mill - an overview ScienceDirect Topics

The rod mill feeds a wet ball mill at a feed size of 1.0 mm (1000 μm) and produces a product with 80% passing a 150 μm screen. The rod mill is in an open grinding circuit.

获取价格

Good Price Rod Mill Manufacturers - Discount Rod Mill

Advantages of Rod Mill. 1. Compared with the sliding bearing bracket, the rod mill can save 10 energy and increase the production capacity by 20%. 2. The Rod mill can use a high voltage motor. 3. Adopts large gear oil

获取价格

Australia's Best Grain Mills Home Flour Mills Grain Grinders ...

Our range of home flour mills grain mills are Australia‘s best stone grain mills for sale. Not only are these grain mills all built to last, their gorgeous craftsmanship is an asset to any kitchen that needs a small flour mill for home use.The many benefits of being able to mill flour at home become apparent as soon as you taste it. Our electric grain mills retain all

获取价格

Grinding and milling equipment - SHAPA

Size reduction machines still mill harvested materials but also a vast variety of other food, chemical, pharmaceutical and mined materials too ... Grinding and milling equipment . ... to grind minerals, the mined products are tumbled amidst heavy balls or long heavy rods which have a crushing action – hence the existence of Ball Mills and Rod ...

获取价格

Rod Mills Grinding Mills DOVE

DOVE Rod Mills are supplied in a wide range of capacities and specifications. DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr – 20 Kg/Hr).

获取价格

Grindmaster 950 - Perfect for professional Grinding

The superior thing about the Grindmaster stone mill when used in ENGSKO’s decentralized flour mills for milling high class flour at a high yield is that the process only uses 4 milling breaks. In this unique combination of 3 break roller milling and 1 break stone milling the stone grinding machine produces a high quality, fine flour from the ...

获取价格

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments. Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders. They are versatile tools that offer efficient and reliable grinding and mixing capabilities.

获取价格

Rod Mill Grinding - 911 Metallurgist

2017/7/4 The experimental part of this program was aimed at performing a detailed analysis of the breakage kinetics in a batch rod mill in order to develop a better understanding of the breakage sub-process in a rod mill and to obtain the quantitative information necessary to study the applicability of the linearized batch grinding model to

获取价格

Bond Rod Mill Work Index Equipment Apparatus Review - 911

2016/3/31 Commentary on the apparatus of the Bond rod mill Work Index by Alex Doll December, 2015 alex.doll@sagmilling The Bond “Third Theory” of comminution was originally divided into three size classes reflecting the varieties of comminution equipment common during the time period when Bond (and his collaborators) were

获取价格

Grinding Mills – MechProTech MPT

The PLC is programmed to monitor the power draw of the ball mill. As grinding media gradually depletes in the ball mill, so does the power draw. ... Deviation for a set point then activates the machine to dispense grinding media into the weigh hopper, where it is reordered prior to a pneumatic gate opening and allowing it to discharge in the ...

获取价格

Ball Mills - Suitable for every application Retsch

Ball mills are furthermore characterized by significant differences in the sizes of available grinding jars. Retsch offers mills with jar capacities from 1.5 ml up to 150 l and balls are available from 0.1 mm to 40 mm, see Figure 2. ... which also has a great influence on the result of a milling process, is the power of a mill. Depending on the ...

获取价格

Milling vs Grinding: What's the Difference? - OneMonroe

2020/2/26 Milling and grinding aren’t the same, however. They each work in a different way to remove material from a workpiece. What Is Milling? Milling is a machining process that involves the use of a milling machine to remove material from a workpiece. Milling machines feature cutting blades that rotate while they press against the workpiece.

获取价格

Stone Flour Grinding Mill for Wheat, Corn, Grain, Pulses

A healthy grinding. The heart of the stone mill is the millstone. The size of the millstone is not decisive for the fineness of the flour. However, the optimal combination of the millstone’s diameter and its speed, controlled by a three-phase motor, is fundamental. The combination of rotation speed and gap between stones ensures perfect milling at low temperature to

获取价格

Ball Mill Rod Mill Design - 911 Metallurgist

2016/4/21 In all ore dressing and milling processes, including flotation, cyanidation, gravity concentration, and amalgamation, it is necessary to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent

获取价格

Rod Mill - an overview ScienceDirect Topics

The rod mill feeds a wet ball mill at a feed size of 1.0 mm (1000 μm) and produces a product with 80% passing a 150 μm screen. The rod mill is in an open grinding circuit. Determine: 1. the shaft power of the rod mill, 2. the size of the industrial mill. Data: Laboratory Standard Bond Test: Rod Mill: Grindability index at 10 mesh = 13.5 kWh/t ...

获取价格

Ball mill, Ball grinding mill - All industrial manufacturers

Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller. ... you get with our FT Series Grinding Mills. ... vertical stone dry milling. Contact. ball grinding mill. MaxxMill series. Output: 190, 800 t/h

获取价格

Stone Flour Grinding Mill for Wheat, Corn, Grain, Pulses

A healthy grinding. The heart of the stone mill is the millstone. The size of the millstone is not decisive for the fineness of the flour. However, the optimal combination of the millstone’s diameter and its speed, controlled

获取价格

Ball Mill Rod Mill Design - 911 Metallurgist

2016/4/21 In all ore dressing and milling processes, including flotation, cyanidation, gravity concentration, and amalgamation, it is necessary to crush and grind, often with rob mill ball mills, the ore in

获取价格

Rod Mill - an overview ScienceDirect Topics

The rod mill feeds a wet ball mill at a feed size of 1.0 mm (1000 μm) and produces a product with 80% passing a 150 μm screen. The rod mill is in an open grinding circuit. Determine: 1. the shaft power of the rod mill, 2. the size of the industrial mill. Data: Laboratory Standard Bond Test: Rod Mill: Grindability index at 10 mesh = 13.5 kWh/t ...

获取价格

Ball mill, Ball grinding mill - All industrial manufacturers

Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller. ... you get with our FT Series Grinding Mills. ... vertical stone dry milling. Contact. ball grinding mill. MaxxMill series. Output: 190, 800 t/h

获取价格

Road Milling: What Is It? How Does It Work? - KoneCarbide

2022/8/11 A cold milling machine performs pavement milling, also called a cold planer, mainly comprising a milling drum and a conveyor system. As mentioned above, the milling drum is used to remove and grind the asphalt surface by rotating. The milling drum rotates in the opposite direction of the machine’s moving direction, and the speed is lower.

获取价格

Used Rod Mills for sale. Morgan equipment more Machinio

Search for used rod mills. Find Morgan, Symons - , Allis-Chalmers, Waterbury, Danieli, Simac, Standard Industrial, and Cantek for sale on Machinio. ... Eccentric vibrating mill Type ESM Ball Mill Usable volumn is 5 liter maximum Total grinding tube volume is 19 liters, grinding medea volume is 15 liters 235 mm ID x 450 mm L. Unit is ...

获取价格

What’s the Difference Between Ball Mill, Rod Mill and SAG Mill?

2020/3/20 The biggest feature of SAG mills is the large crushing ratio, which can crush and grind the materials to 0.074mm at one time, accounting for more than 20% to 40% of the total product. The crushing ratio can reach 4000 ~ 5000, which is more than ten times higher than that of the ball mill machine and rod grinding machine. Grinding Material ...

获取价格

What Is a Ball Mill and How Does It Work? (Overview 2024)

2024/7/12 Rod mills have higher efficiency for grinding within the 5 mm—0.4 mm range than mills, making them suitable for applications requiring larger particles to be ground. Understanding Mills The marvels of modern engineering have brought us various types of mills, including the conical mill, which functions to grind and blend materials via

获取价格

Laboratory Rod Mill - JXSC Machine

XMB Laboratory Rod Mill is an efficient laboratory grinder for laboratory wet grinding of fine ore or other material flow, general materials can also be used as dry grinding. A small, light, multi-purpose grinding equipment. The steel rods and steel balls can be interchanged to be used as a ball mill or rod mill.

获取价格

Rod Mill SpringerLink

2023/5/3 End Peripheral Discharging Rod Mill. The end peripheral discharging rod mill feeds the material from one end through the mill journal, and discharges the grinding products from the other end of the mill to the adjacent ring groove with the help of a number of circumference holes (Fig. 2).The structure of end peripheral discharging rod mill is

获取价格

Ball Mills - 911 Metallurgist

2017/2/13 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for

获取价格

AMIT 135: Lesson 8 Rod Mills – Mining Mill Operator Training

Explain problems associated with rod milling. Summarize considerations in rod mill selection; Reading Lecture Introduction . Used as the primary comminution unit in a grinding circuit. Rods are placed parallel along the length of the rod mill. Rods are 150mm shorter than the mill length.

获取价格

Effect of Rod Mill Feed Sizing on Grinding Performance - 911

2018/3/30 There is no reported evidence that feed size has any effect on rod mill power draw. Because the solids in the rod mill are known to appreciably expand the mill charge (as observed in the charge level before and after grinding out the mill), there would likely be a tendency for power draw to be lower with coarser feeds and at higher feed rates.

获取价格

KoMo Classic Electric Grain Mill Corn Wheat Grinder Stone Burr

The KoMo Classic mill is available in the standard 110V version for use on U.S. power, or a 230V version for use overseas. Mills with 230V power are equipped with a Euro plug. For more details about the Classic mill, see the specs tab, above. At Pleasant Hill Grain, our experience spans the milling spectrum from home-use to commercial.

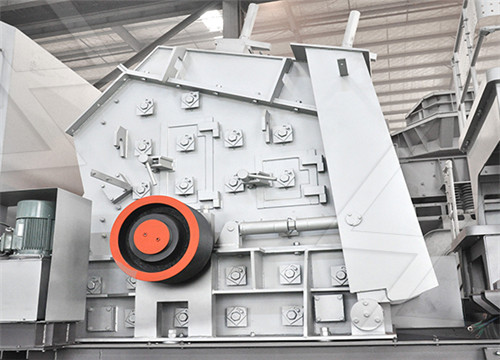

获取价格- مطحنة المطرقة الطارد الأمريكية

- كسارة محجر المعدات

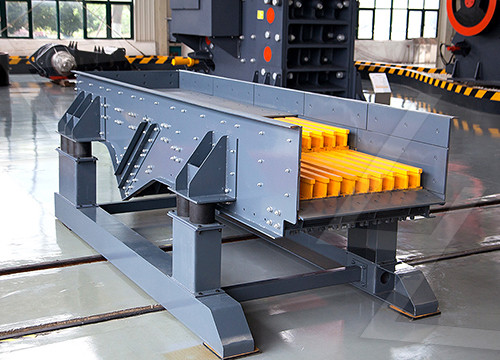

- تهتز الشاشة للرمل والحصى

- مواصفات مطحنة مطرقة كسارة

- اسماء محاجر مشهورة في فلسطين من اليوتي

- كسارة باتو rahang كسارة باتو rahang tanaman

- كسارة تصادمية المنغنيز في سوريا

- لفاف الكسارات التكلفة

- كسارات الحجارة النباتات في تركيا

- مقاومة للحرارة الحزام الناقل

- مطحنة عالية الجودة للخام الخام

- ماكينات تعدين خام الحديد المستعملة للبيع

- 3d آلة الجسر والطحن

- سعر معدات مصنع الجبس العفن

- تصنيع فرن للحديد الفورجية

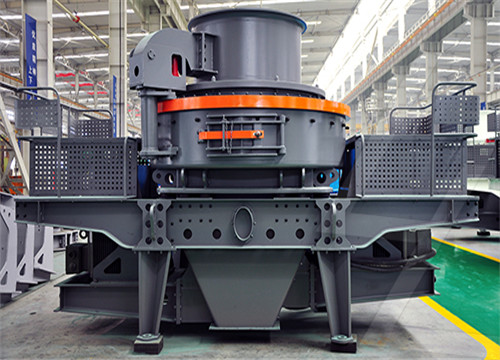

- سعر كسارة vsi سعر موردي كسارة vsi

- http sbm vmexch shimano com sg exchange

- كسارات الأنقاض المحمول

- المصنعة الحزام الناقل

- نفايات المزرعة نشارة بيليه مطحنة بيليه قشر الأرز مطحنة

- الكسارات الفلبين equnipent محطم المحمول

- مطحنة الأسطوانة محطم الصخور

- معدات السيليكا اللازمة

- سعر طاحونة بيجو

- صغيرة rentalcanada محطم

- حزام ناقل لخامات المنغنيز الهند

اقرأ أكثر

اقرأ أكثر