اطلب اقتباس

Magnetic Separation In Mineral Processing

Magnetic separation in mineral processing - Multotec

Learn how magnetic separation is used to separate iron-bearing minerals from non-ferrous minerals in various industries. Explore Multotec Australia's range of magnetic separators for mineral processing

获取价格

Magnetic Separation SpringerLink

2022/2/28 In mineral processing, magnetic separation is usually employed for three purposes: Ejection of iron and other similar materials present in the p stream to

获取价格

Magnetic Separation: Principles, Devices, and

2023/10/30 Magnetic separation, thanks to its advantages of large processing capacity, low operation cost, high efficiency and applicability, and environmental friendliness in comparison to other separation

获取价格

Chapter 2 Magnetic Separation - Springer

Magnetic Separation 2.1 Introduction The differences in magnetic susceptibility can be utilized to separate a valuable mineral from its gangue through the magnetic separation

获取价格

Separations Free Full-Text Application of Magnetic

2024/4/24 Magnetic separation technology is commonly used in the field of mineral processing engineering for magnetite, hematite, titanite, and other magnetic ferrous metal oxide minerals. ... Magnetic

获取价格

Centrifugal dry magnetic separation of fine magnetic minerals

2024/4/5 A full-scale cDMS-1000 separator [23] was particularly developed to separate a fine-grained magnetite ore, to confirm the feasibility of this new DMS

获取价格

Magnetic Separation SpringerLink

2023/4/13 Magnetic separation is widely used. All materials with magnetism in the magnetic field can be treated by magnetic separation, which is the main method to treat

获取价格

Dry High-Intensity Magnetic Separation In Mineral Industry—A

2017/5/22 ABSTRACT. High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the

获取价格

Magnetic Separators For Mineral Processing - Bunting

2018/10/22 Learn how magnetic separators can be used to separate minerals based on their magnetic properties and size. Compare different types of magnetic separators, such as rare earth roll, induced roll and

获取价格

Magnetic separation - Wikipedia

Magnetic separation is the process of separating components of mixtures by using a magnet to attract magnetic substances. [1] The process that is used for magnetic separation separates non-magnetic substances from those which are magnetic. This technique is useful for the select few minerals which are ferromagnetic (iron-, nickel-,

获取价格

Physical Concentration of Heavy Minerals: A Brief Review on

2023/12/12 Pre-concentration of HM, often referred to as a mineral processing route, is focused on the rejection of waste (gangue) minerals in the early or initial stages of the mineral concentration process. ... A review of the theory of magnetic separation of mineral particles and its mechanism is covered in detail elsewhere.

获取价格

Mineral processing - Concentration, Separation,

Mineral processing - Concentration, Separation, Flotation: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill. In large-scale operations this is

获取价格

Magnetic Separation In Mineral Processing

2023/12/28 Magnetic Separation Examples: Examining specific applications and magnetic separation examples underscores the profound impact of magnetic separation in mineral processing. Within the domain of iron ore refinement, magnetic separation emerges as a critical methodology employed to extract magnetite from associated

获取价格

Mineral Processing SpringerLink

After the 1960s, fine particle gravity separation, fine particle flotation, wet high-intensity magnetic separation, and mineral processing-metallurgy process all saw major development. In terms of mineral processing theories, Rittinger’s Textbook of the Processing Art published in 1867 initiated the preliminary mineral processing theory

获取价格

Mineral processing Metallurgy, Crushing Grinding Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy. ... Magnetic separation; Electrostatic separation ...

获取价格

How Magnetic Separation Optimizes Sorting and Process

Magnetic separation is under utilized in many mineral processing plants. Is this because it is an older, simpler technology and lacks the appeal of new technologies? You may be surprised to ... magnetic separation is a simple, inexpensive method to recover minerals from host ore , or

获取价格

Magnetic Separation Technology for Mineral Processing Plants:

2024/5/9 Magnetic separation technology plays a pivotal role in mineral processing, offering efficient and versatile solutions for separating valuable minerals from gangue materials. By harnessing the magnetic properties of minerals, magnetic separators can selectively capture and concentrate target minerals based on their

获取价格

Magnetic Separation SpringerLink

2023/4/13 Magnetic separation is the mineral separation method to separate different minerals by magnetic differences. ... which were widely used. However, these magnetic separators have small separation space and low processing capacity. In addition, they are only used for the separation of certain metal ores. At the same time,

获取价格

Magnetic Separation in the Mining Industry - Mainland

2015/4/29 Why Magnetic Separation Matters for the Mining Industry ... creates a huge amount of waste product in the form of worthless or low value minerals and unusable man-made materials. ... Magnetic separation machines are usually placed at the beginning of a mine’s materials processing line to remove tramp ore before it can cause harm to ...

获取价格

Magnetic Separators Multotec

Multotec engineers a range of customised magnetic separation solutions for mining processes, that help to improve the efficiency of downstream processing and reduce production costs. These are the reasons why Multotec’s magnetic separators are used in mineral processing plants worldwide. Multotec magnetic separators:

获取价格

Technology of superconducting magnetic separation in

magnetic separation in mineral and environmental processing G. Gillet and F. Diot Abstract The conventional magnetic separators used in the mineral industry are equipped with traditional magnetic circuits or with permanent magnets (rare earth). However, when pro cessing minerals with low magnetic susceptibilities or miner

获取价格

Dry High-Intensity Magnetic Separation In Mineral Industry—A Review

2017/5/22 ABSTRACT. High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the performance of these separators treating different minerals has

获取价格

Minerals Free Full-Text Characterization of Magnetic and ...

2023/11/7 Magnetic separation has wide-ranging applications in both mineral processing and recycling industries. Nevertheless, its conventional utilization often overlooks the interplay between mineral and particle characteristics and their impact on operational conditions, ultimately influencing the efficacy of the separation process. This

获取价格

Magnetic Separators Multotec

Multotec engineers a range of customised magnetic separation solutions for mining processes, that help to improve the efficiency of downstream processing and reduce production costs. These are the reasons why

获取价格

Technology of superconducting magnetic separation in

magnetic separation in mineral and environmental processing G. Gillet and F. Diot Abstract The conventional magnetic separators used in the mineral industry are equipped with traditional magnetic circuits or with permanent magnets (rare earth). However, when pro cessing minerals with low magnetic susceptibilities or miner

获取价格

Dry High-Intensity Magnetic Separation In Mineral Industry—A Review

2017/5/22 ABSTRACT. High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the performance of these separators treating different minerals has

获取价格

Minerals Free Full-Text Characterization of Magnetic and ...

2023/11/7 Magnetic separation has wide-ranging applications in both mineral processing and recycling industries. Nevertheless, its conventional utilization often overlooks the interplay between mineral and particle characteristics and their impact on operational conditions, ultimately influencing the efficacy of the separation process. This

获取价格

6 Magnetic Separation - Springer

6 Magnetic Separation Magnetic separation utilizes the force of a magnetic field to produce differential ... Source: B.A. Wills, Mineral Processing Technology, Pergamon Press, New York, 1979, p. 345. the feed is plucked out by the magnet to be held against the cross-belt, then thrown

获取价格

Separations Free Full-Text Application of Magnetic Separation ...

2024/4/24 Magnetic separation technology is commonly used in the field of mineral processing engineering for magnetite, hematite, titanite, and other magnetic ferrous metal oxide minerals. ... Magnetic separation technology is a physical separation method that uses the differences in magnetism between matter to separate them from each other by

获取价格

Types of Mining Magnetic Separators - Mineral Processing

2024/8/14 Mining magnetic separator is common equipment in mineral processing. And magnetic separation is the main method of iron ore dressing. What minerals are required for magnetic separation? Common Iron Minerals are magnetite (strong magnetic minerals), hematite (weak magnetic minerals), Limonite, specularite, siderite (all weak

获取价格

Technology of superconducting magnetic separation in mineral

1999/8/1 The conventional magnetic separators used in the mineral industry are equipped with traditional magnetic circuits or with permanent magnets (rare earth). However, when processing minerals with low magnetic susceptibilities or minerals of very small particle size, these separators are inefficient. In addition, a conventional magnetic

获取价格

Magnetic and Electrostatic Separation - ScienceDirect

2016/1/1 In mineral processing, low intensity magnetic separation (LIMS) and high intensity magnetic separation (HIMS) are used or WHIMS when carried out wet. The magnetic field of LIMS is ∼1000 gauss using permanent magnets, while the high-intensity units require an electromagnet to reach the higher fields of up to 20,000 gauss 1.

获取价格

Magnetic Separation: A Comprehensive Overview

Magnetic separation plays a crucial role in the extraction and processing of minerals. It is employed for the concentration of magnetic ores, the removal of impurities from valuable minerals, and the recovery of magnetic materials from waste streams generated during mining operations. Magnetic separation is extensively used in recycling ...

获取价格

Centrifugal dry magnetic separation of fine magnetic minerals

2024/4/5 A full-scale cDMS-1000 separator [23] was particularly developed to separate a fine-grained magnetite ore, to confirm the feasibility of this new DMS method.The separator uses a permanent magnet system and its magnetic induction is adjustable. The separator operates in a continuous model, with the processing capacity reaching

获取价格

Processing a rare earth mineral deposit using gravity and magnetic ...

2014/7/1 Gravity separation is used in mineral processing to separate minerals based on differences in specific gravity. The most common and successful type of gravity separator used for fine particle sizes is a centrifugal gravity concentrator (Falconer, 2003). ... Magnetic separation of minerals is based on different behaviours of mineral particles ...

获取价格

Minerals Special Issue : High Gradient Magnetic Separation

Dear Colleagues, Modern high-gradient magnetic separation was initially triggered in the early 1930s. In the recent several decades, it has become one of the key technologies in the exploration of weakly magnetic ores, such as oxide irons, ilmenite, wolframite, and manganese, and in the removal of magnetic impurities form non-metallic ores, such as

获取价格

(PDF) Overview of Mineral Processing Methods - ResearchGate

2015/8/3 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

获取价格- 450 مخروط هيدروليكي سعر محطم

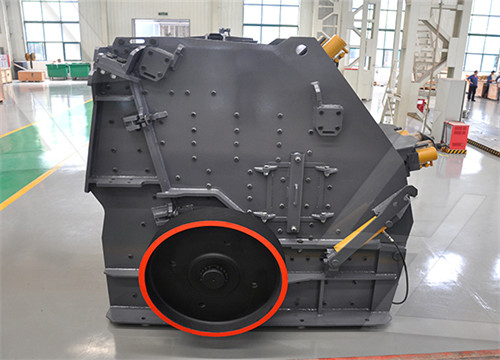

- المطرقة محطم كسارة الحجر حساب محطم مقدمة

- كسارة الفك تصميم حساب تصميم الطاحن الفك

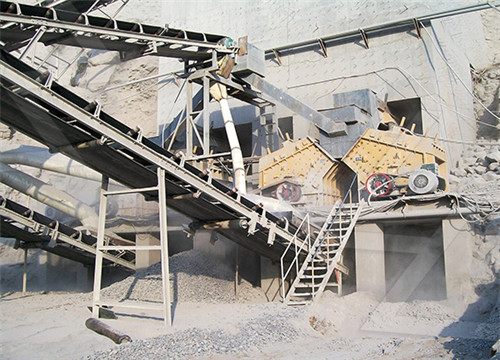

- تصنيع الرمال سحق آلة في مصر

- معلومات كسارة مخروطية

- مجمع مطحنة الصين sewri

- شركات محطة كسارة متنقلة

- جای نمک در ظرفشویی حایر

- معدات التعدين لرابطة الدول المستقلة روسيا

- سیستم صفحه نمایش ارتعاشی

- أنواع صمامات التحكم

- بيع معدات تكسير الفحم الجزائر

- المواد محطم حلقة محطم هو ما

- المحجر المحمول كسارات الحجر الصين

- أنواع طرق التعدين في زيمبابوي

- آلة طحن مطحنة معدنية تستخدم للبيع الجزائر

- تكلفة آلة تكسير الحجارة في السعودية

- سعر مصنع كسارة الحجر tph السعر في الإكوادور

- مطاحن التخشين لفة حجم حفلة موسيقية

- Mounted Points And Small Grinding Wheels

- حفاضات الطفل الكامل ماكينة هيدروليك فيديو

- تأجير كسارة الحجر المتنقلة

- برق صنعتی میل

- مطحنة لفة للحديد معالجة خام

- سعر كسارة متنقلة 100 طن في الساعة

- كسارة المطرقة في خط تكسير الحجر

اقرأ أكثر

اقرأ أكثر