اطلب اقتباس

Ultrafine Iron Powder Grinding

Energy-Efficient Advanced Ultrafine Grinding of Particles Using

Production of ultrafine iron powder by low-temperature

grinding. The particle size distribution is within 1–20 lm, with D 50 = 6.43 lm and D 90 = 11.85 lm, where D 50 is the maximum particle size when the cumulative distribution is

获取价格

A novel approach to enhance decrepitation temperature and

2024/7/24 Li et al. investigated the effect of high-pressure roller grinding on the performance of green pellets derived from ultrafine iron ore concentrate powder with

获取价格

Rheological and mechanical properties of full-tailings backfill ...

2024/2/23 During the grinding and mineral flotation, approximately 4% of the ultrafine powder particles of size less than 1 µm was generated in the original iron

获取价格

Micron-sized ultrafine iron powder preparation method

A. iron superficial oxidation iron scale of burning away the refuse is adopted to be raw material; After magnetic separation, add a certain amount of graphite, in high energy ball

获取价格

Study on preparation and corrosion property of ultrafine

ticle size of iron powder was about 60 μm, that of graphite powder was about 3 μm, that of copper powder was about 30 μm, and that of manganese powder was about 10 μm.

获取价格

Ultra Fine Pure Iron Powder - JFEスチール株式会社

UFPI powder is a high-purity ultrafine iron powder with an average particle size of less than 1 µm which can be handled in the air. (1) The UFPI powder core shows high

获取价格

Effects of ultrafine grinding on physicochemical, functional and ...

2020/6/29 With a reduced particle size, the solubility of ultrafine powders increased significantly (P < 0.05), whereas the water holding and swelling capacities decreased

获取价格

Preparation of ultrafine polypropylene/iron composite powders

2004/2/1 The pan-milling of iron powder was conducted in the same manner. PP/Fe composite (PP/Fe 90/10 wt.%) powders obtained were compressed into sheets at 190

获取价格

CLUM Ultrafine Vertical Grinding Mill

The internal uses PLC intelligent control, the external uses the touch screen to display and adjust the system parameters in real time. Modular excuses are reserved, and the scalability is strong, which can quickly realize the

获取价格

How to Grind Quartz Crystals: The Ultimate Guide - 33rd Square

2023/10/19 Screen powder to verify grinding results using a sieve shaker. Further regrind as needed. 4. Final Grinding. For ultra-fine powder, pass the 200 mesh quartz powder through a second ball mill equipped with tiny milling beads. Mill for several hours to achieve a grind size down to 2 microns for electronics applications.

获取价格

Optimization of some parameters of stirred mill for ultra-fine grinding ...

2011/3/10 Under the optimum grinding parameters, an iron concentrate with an iron grade of 68.18% and an iron recovery rate of 94.17% were obtained by two-stage magnetic separation. The successful case of ceramic medium stirring mill replacing two-stage ball grinding provides a feasible solution for energy conservation and consumption reduction

获取价格

Ultra Fine Grinding Mill - Ultra Fine Powder Grinder AGICO

What Is Ultra Fine Grinding Mill. The ultrafine powder grinding system is a new product independently developed by our company, mainly used to grind and classify various non-metallic ores in cement plants, such as the grinding of limestone powder, deep processing of pulverized coal, etc.This system is composed of an elevator, airlock device, superfine

获取价格

Limestone Ultrafine Mill Machine - SBM Ultrafine Powder

2021/9/13 The limestone ultrafine mill machine is a highly efficient industrial grinding mill. It can grind limestone into a fine powder (150-3000 mesh), and the fineness can be adjusted freely. In addition, it can also grind 100+ kinds of non-metallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black,

获取价格

Fine Powder Grinding Mill Quadro Fine Milling Machine

The F10 fine grind mill is an advanced fine powder grinding machine, producing the highest percentage within the target PSD of any existing fine milling technology. For D50 milling in the 5–45 micron (< 325 U.S. standard mesh) range, the Quadro ® Fine Grind F10 delivers unsurpassed particle size consistency and maximum on-spec yield. Used to ...

获取价格

Rheological and mechanical properties of full-tailings backfill ...

2024/2/23 During the grinding and mineral flotation, approximately 4% of the ultrafine powder particles of size less than 1 µm was generated in the original iron tailings sand. In addition, the surface minerals of these ultrafine powder particles were slightly amorphous, and a small amount of amorphous SiO 2 and Al 2 O 3 dissolved in an

获取价格

Hydration characteristics investigation of iron tailings blended

2022/1/1 Generally, a particle less than 0.075 mm is defined as an ultra-fine powder. After screening and comparison, it is found that most of the IOTs are less than 0.15 mm. Therefore, the IOT between 0.075 mm and 0.15 mm was selected to conduct mechanical activation experiments after drying and sieving to improve the grinding efficiency and

获取价格

A novel approach to enhance decrepitation temperature and

2024/7/24 Li et al. investigated the effect of high-pressure roller grinding on the performance of green pellets derived from ultrafine iron ore concentrate powder with sulfuric acid residue. Even at an 80% ultrafine iron ore concentrate and 20% sulfuric acid residue ratio, there was little improvement in the green pellets’ decrepitation temperature.

获取价格

Preparation of ultra-fine iron powders by water-gas atomization

The physical properties and the micro morphologies of the ultra-fine iron powder, the reduced iron powder and the carbonyl iron powder were compared. The sintered blocks of three kinds of iron powders were prepared under a certain hot pressing process, and their fracture morphologies and mechanical properties were investigated.

获取价格

CLUM Series Ultrafine Vertical Roller Mill - SBM Ultrafine Powder ...

The ultrafine vertical grinding mill integrating ultrafine powder grinding, grading and transporting has become a better choice in the ultrafine powder grinding industry. Product Performance. 1. Higher Yielding Rate, Better Quality ... If there are any impurities like iron blocks in the materials, as they move towards the fringe of the grinding ...

获取价格

HYM Ultra-fine Powder Grinding Mill China First Engineering ...

HYM ultra-fine powder grinding mill Overview: HYM ultra-fine powder grinding mill can grind kaolin, limestone, calcite, marble, talc, barite, gypsum, dolomite, bentonite, mica, pyrophyllite, sepiolite, diatomite, graphite, alumite, fluorite, potassium etc., more than 100 kinds of non-flammable and explosive materials with humidity less than 6% and Mohs

获取价格

Ultrafine Grinding Process SpringerLink

2023/7/20 After being processed with the ultrafine grinding process, mica powder will be transformed from stratified to granulous powder. Concerning the abovementioned common particle size of fine grinding and ultrafine grinding in metallic ore, we have to adopt the corresponding energy consumption law because the original three energy

获取价格

Production of ultrafine iron powder by low-temperature

grinding. The particle size distribution is within 1–20 lm, with D 50 = 6.43 lm and D 90 = 11.85 lm, where D 50 is the maximum particle size when the cumulative distribution is 50%, and D ... Production of ultrafine iron powder by low-temperature hydrogen reduction: properties change with temperature ...

获取价格

CLUM Series Ultrafine Vertical Roller Mill - SBM

The ultrafine vertical grinding mill integrating ultrafine powder grinding, grading and transporting has become a better choice in the ultrafine powder grinding industry. Product Performance. 1. Higher Yielding

获取价格

HYM Ultra-fine Powder Grinding Mill China First Engineering ...

HYM ultra-fine powder grinding mill Overview: HYM ultra-fine powder grinding mill can grind kaolin, limestone, calcite, marble, talc, barite, gypsum, dolomite, bentonite, mica, pyrophyllite, sepiolite, diatomite, graphite, alumite, fluorite, potassium etc., more than 100 kinds of non-flammable and explosive materials with humidity less than 6% and Mohs

获取价格

Ultrafine Grinding Process SpringerLink

2023/7/20 After being processed with the ultrafine grinding process, mica powder will be transformed from stratified to granulous powder. Concerning the abovementioned common particle size of fine grinding and ultrafine grinding in metallic ore, we have to adopt the corresponding energy consumption law because the original three energy

获取价格

Production of ultrafine iron powder by low-temperature

grinding. The particle size distribution is within 1–20 lm, with D 50 = 6.43 lm and D 90 = 11.85 lm, where D 50 is the maximum particle size when the cumulative distribution is 50%, and D ... Production of ultrafine iron powder by low-temperature hydrogen reduction: properties change with temperature ...

获取价格

Ultrafine Grinding - an overview ScienceDirect Topics

Advances in the Cyanidation of Gold. G. Deschênes, in Gold Ore Processing (Second Edition), 2016 4.4 Ultrafine Pyrrhotite Concentrate. Ultrafine grinding is used to liberate gold finely disseminated in metallic sulfides. KCGM is the first gold mine using ultrafine grinding followed by cyanidation (Ellis and Gao, 2002).The gold sulfide concentrate is

获取价格

Parametric study on four station ball mill for synthesis of ultrafine ...

2023/4/28 Changing the type of grinding media can help find the best one for making the right size and distribution of particles. The type of powder may affect both the milling process and the finished product. Changing the type of powder being milled can help find the best way to create the right particle size and distribution [8], [9].

获取价格

Ultra Fine Grinding - A Practical Alternative to Oxidative

Ultra Fine Grinding UFG mills overcome these limitations by the use of rotating stirrers inside a stationary mill shell. Ultra fine grinding mills have been in use for many years in a large number of every day applications such as pharmaceuticals, dyes, clays, paint and pigments before being used in the mineral processing industry.

获取价格

LUM Ultrafine Vertical Grinding Mill - sbmchina

The ultrafine vertical grinding mill integrating ultrafine powder grinding, grading and transporting has become a better choice in the ultrafine powder grinding industry. Product Features: Higher capacity, better powder quality, more excellent comprehensive performances ... For sundries like iron block in materials, when they move to the fringe ...

获取价格

Preparation of high-purity reduced iron powder by Höganäs

2023/11/4 In this study, firstly, an ultra-pure magnetite concentrate with 72.12% Fe and 0.09% Si was obtained by reverse flotation from superior magnetite concentrate with 68.38% Fe and 2.33% Si. Then, using the ultra-pure magnetite concentrate as raw material, high-purity reduced iron powder with Fe grade of 99.06% was prepared by Höganäs

获取价格

Ultra-precision grinding - ScienceDirect

2010/1/1 Stephenson et al. [177] ground BK7 with ELID grinding and used a cast iron-bonded cup with a grain size of 2 μm at a wheel speed of 39 m/s, 5 μm depth of cut and feed rate of 5 mm/min. The diameter of the cup wheel was 124 mm with a width of 4 mm. ELID grinding is influenced by the duty ratio and peak voltage. These parameters

获取价格

Powder Grinding Mills Engineered by FTM Fote Machinery

②Ultrafine Grinding Mill: $14,600/set (the lowest price). It is an upgraded Raymond mill for making micro powder and fine powder. Widely applied in metallurgy, mining, chemical, cement, construction, refractory materials, ceramics, and other industries.

获取价格

Application of Ultra-fine Grinding Technology in Food Processing

2021/2/12 Ultra-fine grinding technology is a new technology developed in the past 20 years. The so-called ultra-fine grinding refers to the use of mechanical or hydrodynamic methods to overcome the internal cohesive force of solids to grind them, thereby grinding the material particles of more than 3 mm to 10-25 microns.

获取价格

Effect on Fine Particles Output Characteristics of Ceramic Ball Grinding

2023/11/7 Steel balls as traditional grinding media are prone to excessive fines generation and high energy consumption. Therefore, in light of this problem, the authors investigated another media—ceramic balls based on the output characteristics of fine particles. This study discusses the effect of ceramic balls on the change of the particle

获取价格

Ball mills dry grinding systems fine powder processing

A ball mill is still the preferred solution for many types of dry grinding duty. A ball mill consists of a rotating horizontal cylinder, containing a cascading grinding media, typically steel or ceramic balls, in the range of 10 to 100 mm diameter. The grinding mechanism takes place within the falling and sliding grinding media.

获取价格- سائقي تعدين خام الحديد الوظائف الشاغرة

- لفة طحن آلة معدنية

- چین آسیاب نورد سرد

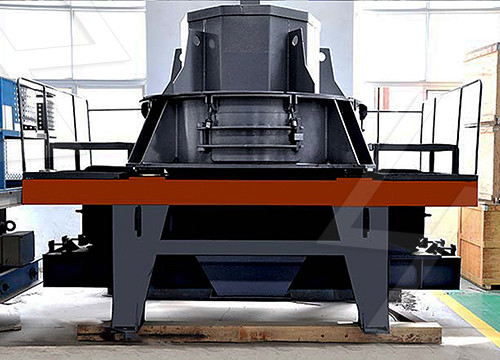

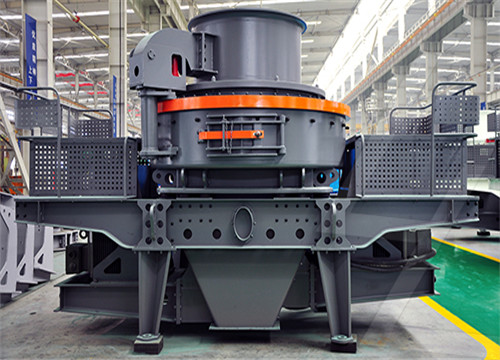

- رمح الرأسي منتج محطم في مصر

- الحديد أساسيات معالجة إثراء خام

- قضيب مطحنة لفات ميتسوبيشي البرازيل

- إزالة الطلاء ساندر

- مطحنة لطحن عينات حطب

- الحصى والحجر محطم على

- محطم العمودي 1200

- اسعار مطحنة المطرقة في العراق

- استاتیک سنگ خرد کن بوته

- كسارة فكية متنقلة من جهة ثانية

- مصنعي آلة الطاحن في بنغالور

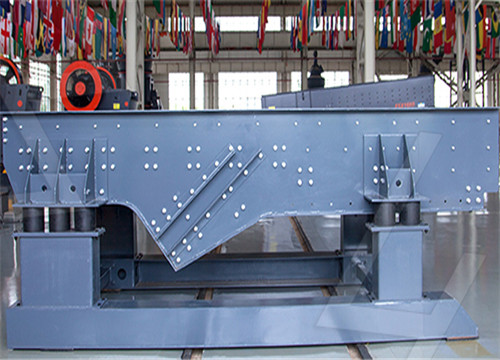

- شرح مبدأ ووظيفة الشاشة الاهتزازية

- مطحنة الفحم الدراسة مشغل

- معدل ما حفر في معدات التعدين آلة كسارة الحجر

- دليل كسارة تركيب بدف

- شركة اربين الالمانية لتصنيع مطاحن كربونات الكالسيوم

- عملية كسارة الخرسانة المتنقلة

- قطع غيار نظام معالجة الفحم

- Curbside Concrete Crushing

- شرطة الأمن العام تأثير محطم مواصفات

- ثلاثة لفة مطحنة مستحضرات التجميل

- الحصى استخراج آلات للبيع

- الرسم الهندسي لمطحنة الكرة

اقرأ أكثر

اقرأ أكثر