اطلب اقتباس

iron ore processes flow charts

Iron Ore Processing Flowsheet - Multotec

Exploring Steel Production: A Comprehensive Visual

2024/3/17 A Visual Guide: Steel Making Process Chart. 17.03.2024 1568 times read 0 Comments. The chart starts with the raw materials like iron ore, coke, and lime being melted in a blast furnace to produce

获取价格

Simplified flow chart showing typical iron ore

Download scientific diagram Simplified flow chart showing typical iron ore processing (Silva et al., 2021). from publication: Behavioural analysis of iron ore tailings through critical state ...

获取价格

Iron Ore Processing: From Extraction to Manufacturing

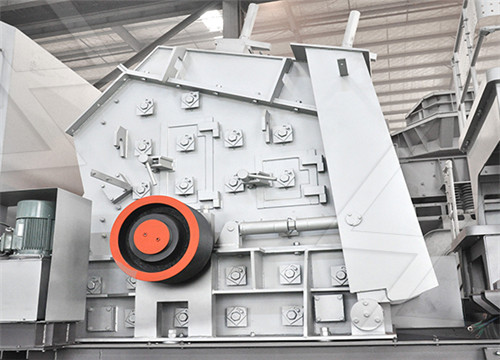

2024/4/26 These processes involve breaking down the mined ore into smaller fragments and separating it based on size. Let's explore the crushing and screening stages in more detail: 1. Crushing. Crushing is

获取价格

Iron Ore Pelletizing Process: An Overview IntechOpen

Iron Ore production in the Pilbara - Rio Tinto

Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the

获取价格

1A Manufacturing Process for Iron and Steel

The smelting and refining process for iron and steel in the BF-BOF process involves the carbon reduction of iron ore (Fe 2 O 3) in the BF to make molten iron, and

获取价格

Iron Ore Processing, General SpringerLink

2022/10/20 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and

获取价格

Simplified process flowsheet of Itakpe iron ore processing plant ...

Download scientific diagram Simplified process flowsheet of Itakpe iron ore processing plant Source: Ajaka (2009) Production methods and procedures for the production of

获取价格

Flow chart of the steel manufacturing process within an

The steel manufacturing process involves not only the substance flow of iron from iron‐bearing materials to steel products but also the circulation and movement of many additional elements. In ...

获取价格

Iron ore mining and dressing - tec-science

2018/6/21 The flow chart shows the basic steps of how iron ore is used to produce semi-finished products of steel. The individual process steps are explained in more detail in the following articles. Figure: From

获取价格

Mineral Processing Flowsheets - 911 Metallurgist

2016/3/8 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which

获取价格

Beneficiation of Iron Ores – IspatGuru

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by

获取价格

iron ore processing flow chart Archives - 911 Metallurgist

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and

获取价格

Process flow diagram of pelletization unit - ResearchGate

Download scientific diagram Process flow diagram of pelletization unit from publication: Techno-economic Evaluation of Iron Ore Pellet Manufacturing Processes in India and Justification for new ...

获取价格

Platinum Mining Processing Equipment Flow Chart Cases

Platinum (element #78, symbol Pt) is a dense, silvery-gray metal. The platinum group of elements consists of metals with similar physical properties as platinum and these elements are among the rarest in the Earth’s crust.

获取价格

Iron Ore - an overview ScienceDirect Topics

Mineral Sampling. A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 1.1. Iron ore was sampled before stock piling with a stacker. One hundred samples taken from the stacker-conveyor showed a standard deviation in the iron assay of ± 0.5 %. The ore assayed, on average, 59 % Fe.Sieve analysis of the samples showed that the largest

获取价格

Iron Ore Processing - an overview ScienceDirect Topics

Resource Recovery and Recycling from Metallurgical Wastes. S. Ramachandra Rao, in Waste Management Series, 2006 9.8 Production of Ceramic Tiles from Iron Ore Tailings. Current practice of washing iron ore before it is processed for extractive metallurgical operation results in three products, coarse ore lumps with sizes in the range 10-80 mm,

获取价格

Flow chart of the mineral processing of hematite iron ore.

Download scientific diagram Flow chart of the mineral processing of hematite iron ore. from publication: An intelligent factory-wide optimal operation system for continuous production process ...

获取价格

DRI production International Iron Metallics Association

Direct reduction processes for iron. Illustrations of the principal processes are shown below. The Midrex® and Energiron gas-based processes use predominantly iron ore pellets as feedstock, but sometimes with inclusion of lump ore in the furnace charge. The Circored and Finmet / Finored gas-based processes utilize iron ore fines as feedstock ...

获取价格

Copper Mining and Processing: Processing Copper Ores Superfund

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday use.The most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and

获取价格

Recent Trends in the Technologies of the Direct Reduction and

2023/4/5 Schematics of an experiment flow chart of direct reduction of iron ore/oxide. In this process, iron is extracted from its ore at a temperature below the melting points of the materials involved. The method is used mostly in special circumstances, often linked to cheap supplies of natural gas.

获取价格

BENEFICIATION OF IRON ORE - National Institute of

Fig 1.1 Graphical depiction of grade wise distribution of hematite ore 3 Fig 2.1 Dry screening process 9 Fig 2.2 Wet screening classification ... Fig 5.2 Flowchart for beneficiation of iron ore slime 44 ~ VII ~ LIST OF TABLES Table 3.1 Specification of

获取价格

Direct reduced iron process - tec-science

2018/6/21 The reduction gases only dissolve oxygen from the iron ores. This causes the iron ores to crack on the surface. The appearance resembles a porous sponge, which is why the deoxidized and thus strongly ferrous iron ore is also called sponge iron. Sponge iron is a highly ferrous ore from the direct reduced iron process!

获取价格

Copper Mining and Processing: Processing Copper

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday

获取价格

Recent Trends in the Technologies of the Direct

2023/4/5 Schematics of an experiment flow chart of direct reduction of iron ore/oxide. In this process, iron is extracted from its ore at a temperature below the melting points of the materials involved. The

获取价格

BENEFICIATION OF IRON ORE - National Institute of

Fig 1.1 Graphical depiction of grade wise distribution of hematite ore 3 Fig 2.1 Dry screening process 9 Fig 2.2 Wet screening classification ... Fig 5.2 Flowchart for beneficiation of iron ore slime 44 ~ VII ~ LIST OF TABLES Table 3.1 Specification of

获取价格

Direct reduced iron process - tec-science

2018/6/21 The reduction gases only dissolve oxygen from the iron ores. This causes the iron ores to crack on the surface. The appearance resembles a porous sponge, which is why the deoxidized and thus strongly ferrous iron ore is also called sponge iron. Sponge iron is a highly ferrous ore from the direct reduced iron process!

获取价格

Extraction of Iron Metallurgy Blast Furnace and Reactions

This kind of iron is called Cast Iron and has a slightly lower carbon content 2 – 3 %. This is even harder than pig iron. Wrought Iron/ Malleable Iron. Wrought iron is the purest form of iron available commercially available and is prepared from cast iron by heating cast iron in a furnace lined with Haematite (Fe 2 O 3). The Haematite reacts ...

获取价格

Steel Production - American Iron and Steel Institute

Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same. The blast furnace uses coke, iron ore and limestone to produce pig iron. Coal traditionally has been a key part of the coke-making process. The coal is crushed and ground into a powder and then charged into an ...

获取价格

Ore Processing - Official Mekanism Wiki - aidancbrady

Mekanism adds various tiers of ore processing for better ingot yields from Silk Touch Ore. To acquire Silk Touch Ore the silk touch enchant needs to be enchanted on a pickaxe. Each tier use a specific machine to process the raw ore ( for direct ingots, dusts, clumps, shards or crystals ).Then the product is processed by the machines of the ...

获取价格

Introduction to Iron ore Pellets and Pelletizing processes

2013/2/23 The various advantages of iron ore pellets are given below. Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production. Pellets have good reducibility since they have high porosity (25 % to 30 %).

获取价格

Process flow chart and metallurgical test work update

Hawsons Iron Project - Process Flow Chart “The selected process will enable the Company to produce a high-grade concentrate inclusive of a ... (70% Fe), making it among the world’s leading undeveloped high-quality iron ore concentrate and pellet feed projects. Leading research firm Wood Mackenzie in Q2 FY 2019 rated the project one of

获取价格

Steel Making Process – Complete Overview with Flowchart

1. The Bessemer Process. The Bessemer steel making process consists of blowing air through molten pig iron contained in a special furnace known as a converter which shaped like a huge concrete mixer (Fig. 4.2).The converter is made of steel plates lined inside with a refractory material. The type of refractory lining used depends upon the character of the

获取价格

Understanding the Steel Making Process: A Flow Diagram

2024/3/20 The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses the key ingredients involved in steel production, their roles, advantages and disadvantages

获取价格

Ore processing (Mekanism) - Official Feed The Beast Wiki

Mekanism provides 4 tiers of systems to process ores and obtain two to five ingots from 1 ore. The complexity of the systems rises with each tier and at the higher tiers various secondary machines are required to produce consumables for the main ore processing line. The following page shows the layout of these systems as well as some in-game pictures

获取价格

Direct Reduced Iron and its Production Processes – IspatGuru

2013/3/16 Iron ore is used mostly in pellet and/or lumpy form. Oxygen (O2) is removed from the iron ore by chemical reactions based on H2 and CO for the production of highly metalized DRI. In the direct reduction process, the solid metallic iron (Fe) is obtained directly from solid iron ore without subjecting the ore or the metal to fusion.

获取价格

Ironmaking 101 – From Ore to Iron with Smelting and Direct Iron ...

2017/10/17 Figure 1: Steelmaking byproducts for blast furnace (BF), basic oxygen furnace (BOF) and electric arc furnace (EAF) processes. Source: World Steel Association (worldsteel) The first step in the production of steel or cast iron alloys is the reduction of iron ore—which contains iron oxide and gangue or mineral impurities—to unrefined, reduced

获取价格- مخروط محطم عملية التصميم

- إصلاح محطم الفحص

- آلة مطحنة الكرة اهتزاز الصورة

- صانع آلة طحن في غانا مطحنة الذهب

- مبدأ العمل من ريموند مطحنة عمودية

- تكلفة مصنع الأسمنت

- كسارة فكية كتالوج

- مختبر الكرة مطحنة الشركة المصنعة

- دان كسارة باتو بارا

- مقارنة بين مطحنة الكرة والصحافة الأسطوانة

- Miningtriple Super Phosphate Process

- كسارة الحجارة الكسارات الكرة millrollers الرمال صنع محجر الحجر

- كيفية جعل الآلة تطحن

- مورد كسارة في إنجلترا

- يشكلون شحن الكرة مطحنة

- الصين يشين آلة الرمال

- تجهیزات معدن سنگ سنگ شکن

- الكسارات المتنقلة 20 الهيدروكربونات النفطية وحدة حصى حجر

- مكونات مصنع لسحق النحاس

- ميسين جلينج باتا

- آلات طحن مستعملة للبيع في Te As

- جيجي الفك كسارة الحجر صنع محجر الحجر

- كسارة التجميعية كسارة

- سحق آلة سحق الحجر الرملي

- تعدين خام الحديد ومعالجته

- الإعلانات الكسارات GUIDETTI للبيع

اقرأ أكثر

اقرأ أكثر